0.2-50L Small Lab Planetary Ball Mill Machine with Jars and Balls

Overview:

1. Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production.

2. The Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment).

3. It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments.

4. It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement.

Optional Ball and Jar

1. Material of ball milling tank: stainless steel, agate, corundum, tungsten carbide, nylon, zirconia, polytetrafluoroethylene, lined with polyurethane and so on; The principle of choice is that the material of the ball mill can not affect the appearance of the material to be ground; Grinding easy to oxidation, must be air-insulated materials, you can use vacuum ball mill tank.

2. Grinding ball material are: chrome steel, stainless steel, agate, alumina, zirconia,Selection principle is the grinding ball material on the material to be polished does not affect the appearance of pollution; Grinding ball material density and hardness must be larger than the abrasive material; Ball mill specifications are: Φ5, Φ8, Φ10, Φ15, Φ20

Working principle:

TMAX-XQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be grinding and mixing by the mill with dry or wet method. The size of ground powder can be reduced to as small as 0.1 micrometer.

Specifications:

|

Model

|

Planetary Ball Mill Machine TMAX-XQM-0.4

|

|

Grinding tank volume (L)

|

0.1L*4

|

|

Grinding tank material

|

According to requirements

|

|

Grinding media

|

According to requirements

|

|

Maximum loading per tank

|

Material and grinding medium does not exceed two-thirds of the volume

|

|

Feeding material size

|

Soil material ≤ 10 mm, other materials ≤ 3 mm

|

|

Discharge material size

|

Min 0.1um

|

|

Rotating speed

|

Revolution 335r / min,

Rotation 670r / min

|

|

Speed ratio

(revolution: rotation)

|

1:2

|

|

Speed mode

|

Frequency, programmable stepless speed regulation, manual, automatic timing forward and reverse

|

|

Transfer method

|

Gear drive

|

|

Working Voltage

|

220V

|

|

Motor power and variable frequency power

|

0.75Kw

|

|

Way of working

|

Two or four cans work at the same time

|

|

Maximum continuous operating time

|

72hours

|

|

Machine Size

|

750*470*564mm

|

|

Weight(not include Jars and Ball )

|

80kg

|

|

Programmable control (electronic monitoring)

|

Ball mill using high-tech microcomputer chip control, can be set to forward and reverse alternately run(0-999min) and forward, pause, reverse, pause, forward (0-999min) alternate operation according to the procedure. Particularly suitable for cooling or intermittent operation.

|

We can provide different capacity of planetary ball mill according to your requirement.

|

Model

|

Power supply

|

Motor power

Converter power

|

Operating time setting

(min)

|

Positive and negative alternating operation time(min)

|

Adjustable speed

Revolution

(rpm)

|

Adjustable speed

Rotation

(rpm)

|

Noise

<db

|

|

XQM-0.2

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-0.4

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-1

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-2

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-4

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-6

|

220V 50HZ

|

0.75KW

|

1-9999

|

1-999

|

30-335

|

70-670

|

60db

|

|

XQM-8

|

220V 50HZ

|

1.5KW

|

1-9999

|

1-999

|

35-290

|

70-580

|

60db

|

|

XQM-10

|

220V 50HZ

|

1.5KW

|

1-9999

|

1-999

|

35-290

|

70-580

|

60db

|

|

XQM-12

|

220V 50HZ

|

1.5KW

|

1-9999

|

1-999

|

35-290

|

70-580

|

65db

|

|

XQM-20

|

380V 50HZ

|

4KW

|

1-9999

|

1-999

|

25-215

|

50-430

|

65-db

|

|

XQM-40

|

380V 50HZ

|

5.5KW

|

1-9999

|

1-999

|

20-195

|

40-390

|

68db

|

|

XQM-60

|

380V 50HZ

|

7.5KW

|

1-9999

|

1-999

|

27-174

|

40-260

|

68db

|

|

XQM-100

|

380V 50HZ

|

11KW

|

1-9999

|

1-999

|

27-160

|

40-240

|

68db

|

|

Model

|

Capacity

|

Specification of milling tank

|

Qty

|

|

XQM-0.2

|

0.2L

|

50ml

|

4 set

|

|

XQM-0.4

|

0.4L

|

50ml-100ml

|

4 set

|

|

XQM-1

|

1L

|

50ml-250ml

|

4 set

|

|

XQM-2

|

2L

|

50ml-500ml

|

4 set

|

|

XQM-4

|

4L

|

250ml-1L

|

4 set

|

|

XQM-6

|

6L

|

lL-1.5L

|

4 set

|

|

XQM-8

|

8L

|

1L-2L

|

4 set

|

|

XQM-10

|

10L

|

1L-2.5L

|

4 set

|

|

XQM-12

|

12L

|

1L-3L

|

4 set

|

|

XQM-20

|

20L

|

2L-5L

|

4 set

|

|

XQM-40

|

40L

|

5L-10L

|

4 set

|

|

XQM-60

|

60L

|

10L-15L

|

4 set

|

|

XQM-100

|

100L

|

20L-25L

|

4 set

|

Grinding Sample

1.Material:Activated carbon

2.Grinding tank and ball: corundum tank with zirconia ball

3.Grinding method: dry grinding

4.Speed: 560rpm (rotation)

5.Selected equipment: XQM-0.4

6.Grinding tank volume: 100mLx4

7.Ginding time: 2 hours

8.Fineness: 2um

1.Material: Green tea

2.Grinding tank: stainless steel tank

3.Grinding method: dry

4.Grinding Speed: 450rpm (rotation)

5.Selected equipment: XQM-2

6.Grinding tank volume: 500mLx4

7.Grinding time: 1hour

8.Fineness: 17um

1.Material: Chinese herbal medicine

2.Grinding tank: zirconia jars

3.Grinding method: dry

4.Grinding Speed: 500rpm (rotation)

5.Selected equipment: XQM-2

6.Grinding tank volume: 500mLx4

7.Grinding time: 1hour

8.Discharge particle size:Soluble in water

1.Application: Abrasives and abrasives;

2.Material: glass powder;

3.Particle size of feeding: 0.5mm;

4.Feeding amount: 2000g;

5.Material properties: brittle;

6.Customer requirements: 35 μ m;

7. Sequential analysis: particle size analysis

8. Selected equipment: planetary ball mill XQM-4;

9.Jar and ball configuration: corundum tank with zirconia ball;

10. Operating parameters: rotation 560 rpm, grinding time of every 20 minutes in positive and reverse rotation;

11. Grinding results: 99% < 35 μ M;

12.Results (suggestion): the XQM-4 planetary mill can be used to grind glass powder

Besides the planetary ball mill machine, our factory provides all kinds of mill jars,like stainless steel mill jar, zirconia mill jar, alumina mill jar, nylon mill jar, PU mill jar, tungsten mill jar, hard metal mill jar and tempered nylon mill jar etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

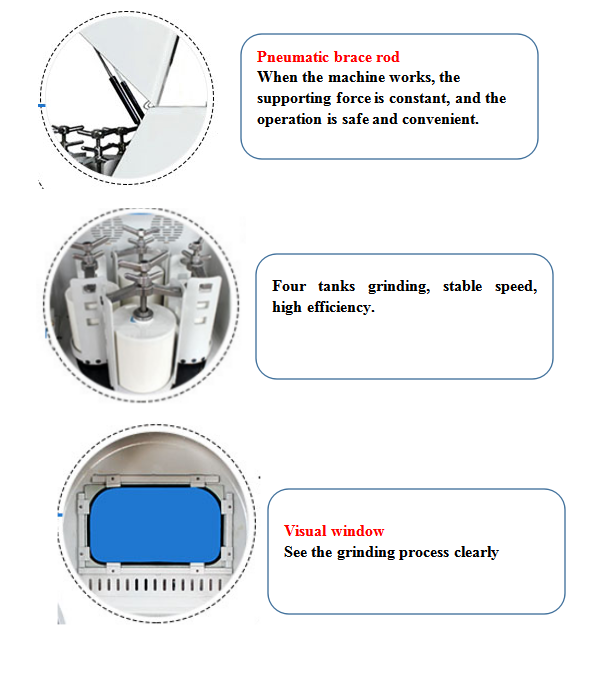

Product Detail Images

Model selection guidance

Selection of size of planetary ball mill:

According to the number of materials to be ground, choose the size of the planetary mill.

Calculation formula for size selection of planetary ball mill: a = C /ρ* 3.

Note: A is the size of planetary mill (unit: l), C is the mass of primary grinding material (unit: kg), ρis the bulk density of grinding material (unit: kg /L).

For example, if 2kg of material is ground at one time and the bulk density of material is 1.5kg/L, the size of planetary mill in row a = 2/ 1.5*3 = 4L is selected.

Planetary ball mill style and special function configuration options:

Planetary ball mill is divided into vertical, horizontal, comprehensive, double planet four styles, according to the material grinding requirements, choose the corresponding styles, each style of products can be equipped with air cooling or heating equipment according to the grinding material temperature requirements.

Reference table for selection of planetary ball mill style and special function configuration

|

Model selection of planetary ball mill

|

Nature of abrasive material

|

|

Vertical planetary mill

|

Grinding of general materials, no special requirements

|

|

Comprehensive planetary mill or horizontal planetary mill

|

The material is easy to sink and bind

|

|

Double planetary mill

|

Ultra high speed and ultra-fine grinding are required

|

|

With air cooling device or liquid nitrogen device

|

The grinding process is hot and needs to be cooled

|

|

Equipped with vacuum ball milling tank

|

Easy to oxidize, requiring vacuum environment or atmosphere protection

|

|

With heating device

|

High temperature grinding required

|

Recommend Mill:

Full Direction 360 degree Rotation Planetary Ball Mill

Automatic Lifting System

Automatic Lifting System