10 Teeth Tungsten Carbide Bush Hammer for Stone Finishing Process

Product Description:

Our 10-tooth tungsten carbide bush hammer is a high-quality tool designed for the stone finishing process and is specifically designed to create a rough and unique pebbled surface finish. Featuring replaceable carbide teeth, the tool revolutionizes traditional manual methods of finishing litchi surface, allowing stone manufacturers to achieve a more uniform appearance, reduce production costs and increase efficiency. Our brush hammer wheels are available in various sizes from 125 to 300 and can also be customized to suit specific requirements.

Product Details:

1. Adjustable roughing and finishing

2. Easy to use, 5 times more efficient than manual methods

3. Adopt high-quality alloy structure, precision welding, durable

4. Affordable price and low overall cost

5. Provide customization options based on customer needs

| Diameter(mm) |

Roller Quantity |

Connection |

Application |

| 125 |

3 |

M14, M16, 5/8"-11 |

Small Bush Hammer |

| 150 |

4 |

| 200 |

4 |

Quick Connector |

Bush Hammer |

| 250 |

5 |

| 300 |

6 |

Depends on themachine |

Sunk Bush Hammer |

| 350 |

8 |

| 400 |

10 |

| 450 |

12 |

| 50 |

1 |

Frankfurt type |

Frankfurt Bush Hammer |

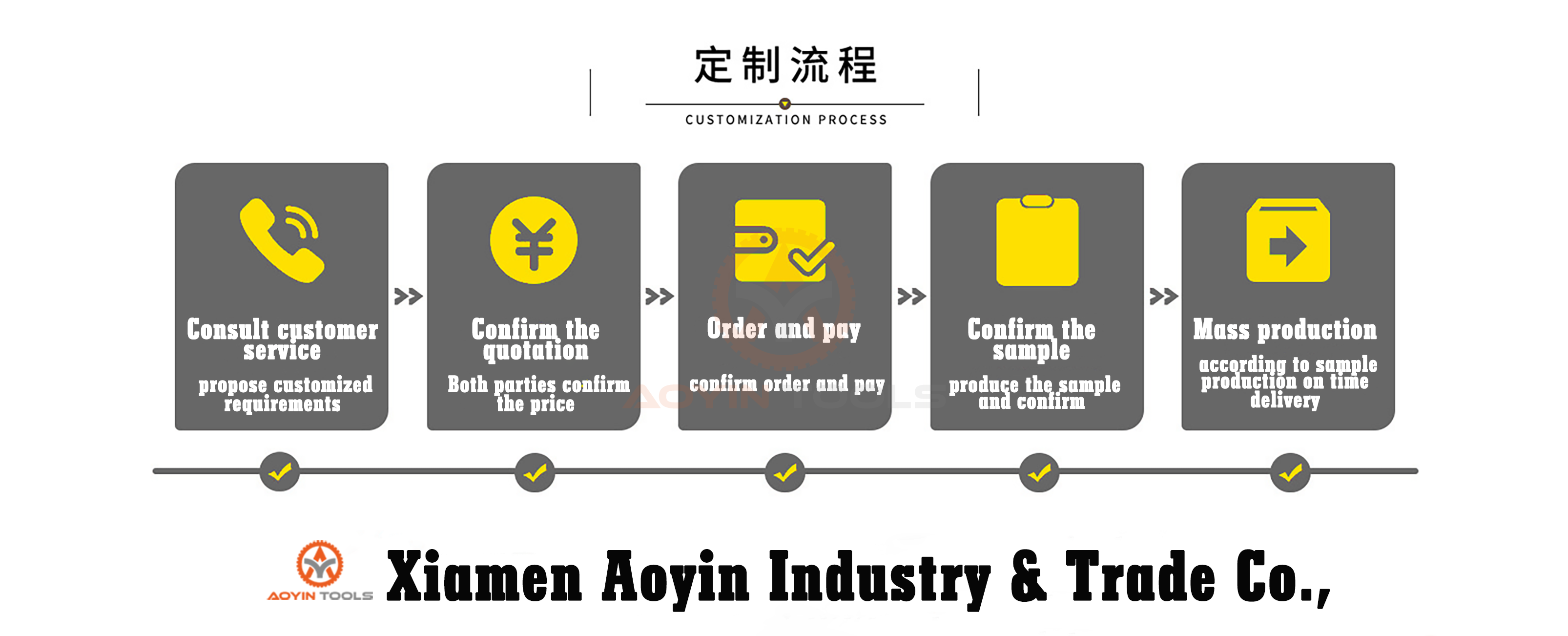

Customization advantages:

1. Greater cost-effectiveness: New formulations and manufacturing processes deliver superior performance at lower costs.

2. Longer cutting life: Designed to reduce cutting costs for users, it's formulated to withstand high temperatures and maintain grip on diamonds for longer life.

3. Stable quality: With the spirit of excellence, meticulous product training and management system, and highly skilled production team, our products have always maintained a high degree of stability.

Application:

Mainly used for grinding and polishing pebbled surfaces on stone and concrete, the bush hammering effect can be adjusted to achieve the desired finish.

This tool significantly improves production efficiency, and the alloy grinding head has high wear resistance and long service life.

In addition to our 10-tooth tungsten carbide bush hammer, we offer a variety of customization options to meet different customer needs. Please contact us for more information, or check our FAQ section for frequently asked questions and answers about our products.

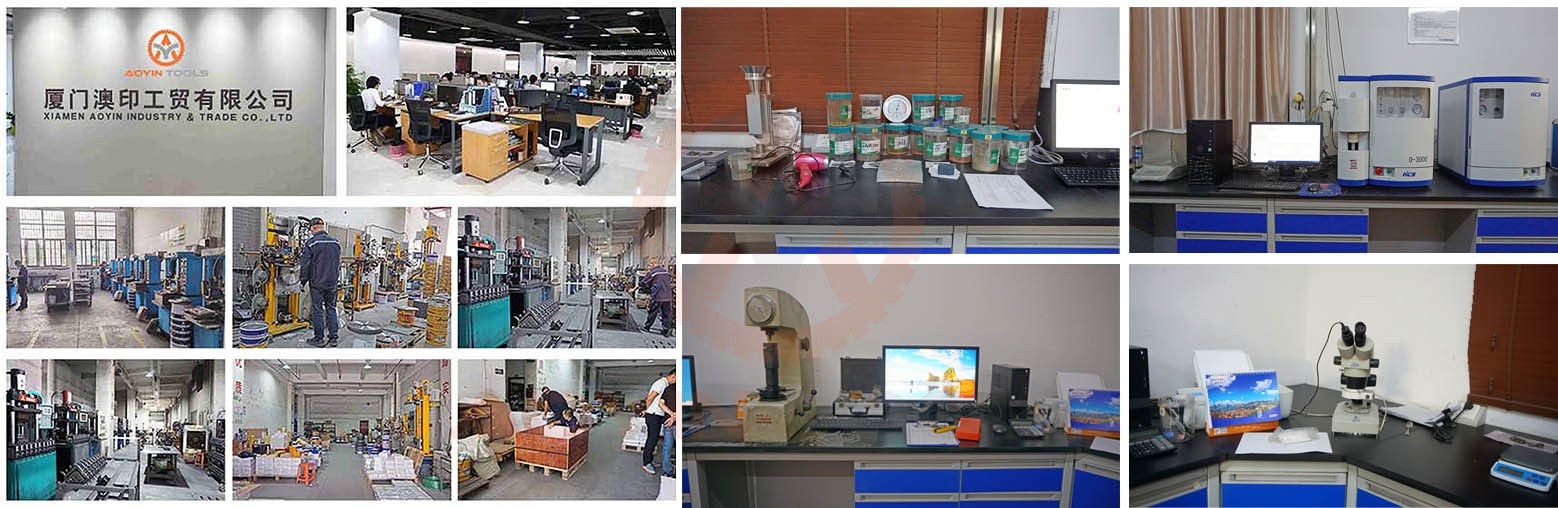

Company Service Advantages:

Our company is committed to providing top-quality products and superior customer service. We prioritize customer satisfaction by delivering reliable products that meet industry standards and expectations.

FAQ - Frequently Asked Questions:

1. Are the carbide teeth on the bush hammer wheel replaceable?

- Yes, the carbide teeth on the bush hammer wheel are replaceable, allowing for easy maintenance and extended use of the tool.

2. What sizes are available for the bush hammer wheels?

- The bush hammer wheels are available in various sizes ranging from 125 to 300, and custom sizes can be made upon request to meet specific needs.

3. How does the bush hammer tool compare to manual methods in terms of efficiency?

- The bush hammer tool is 5-6 times more efficient than manual methods, significantly increasing production efficiency and reducing labor costs.

4. What materials are suitable for use with the bush hammer tool?

- The bush hammer tool is primarily used for stone and concrete surfaces, specifically for creating a rough and unique Lichee-face finish.

5. Is customization available for different specifications or requirements of the product?

- Yes, customization options are available to tailor the bush hammer tool to specific specifications and requirements, providing a personalized solution for customers.