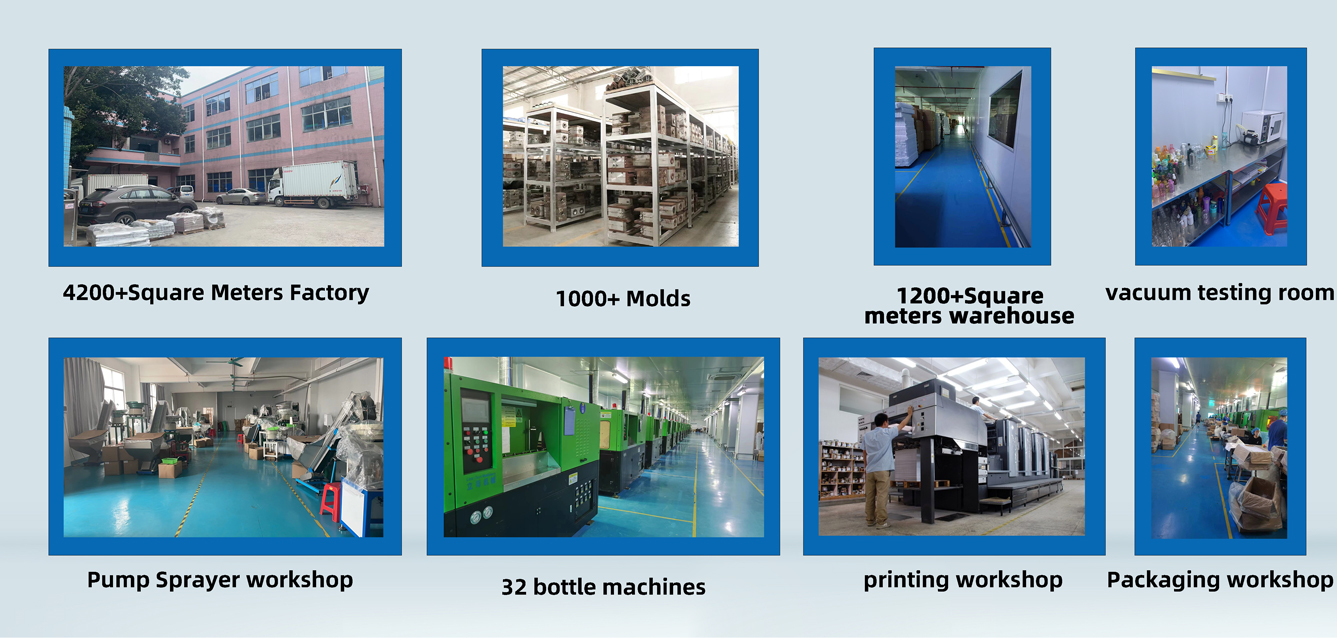

Factory information for 3000ml 3l hdpe hdpe laundry detergent bottle

The detergent bottle is a plastic container specifically designed for packaging and dispensing various types of detergent products. It is commonly used for laundry detergents, dishwashing liquids, and other cleaning solutions. The bottle features a sturdy and ergonomic design, with a secure cap or lid to prevent leakage and maintain product integrity. Its size ranges from small bottles for single-use applications to larger containers for extended use. The bottle's design often includes measurement markings for convenient dosage control.

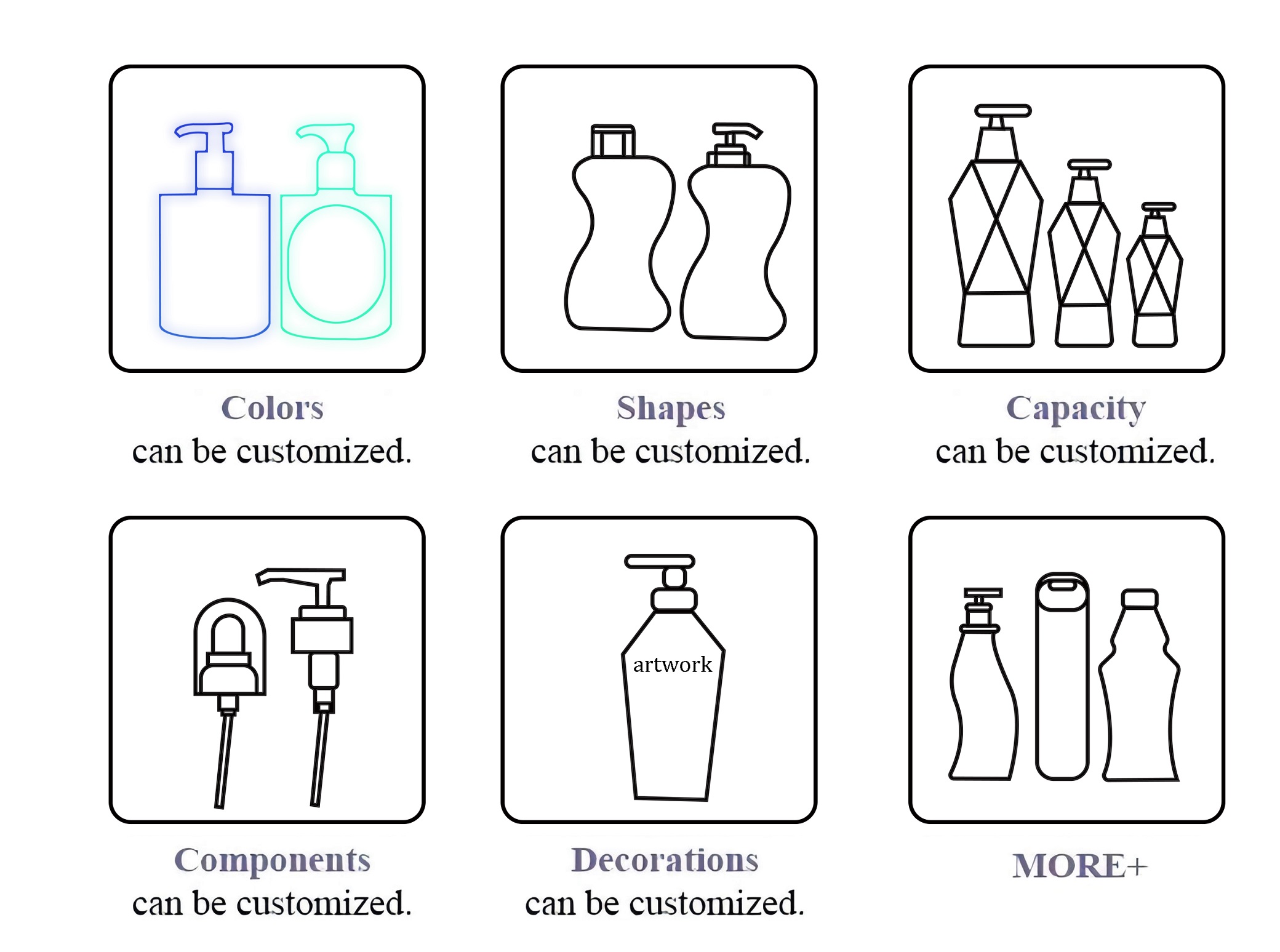

Custom Packaging Solutions for 3L detergent bottle

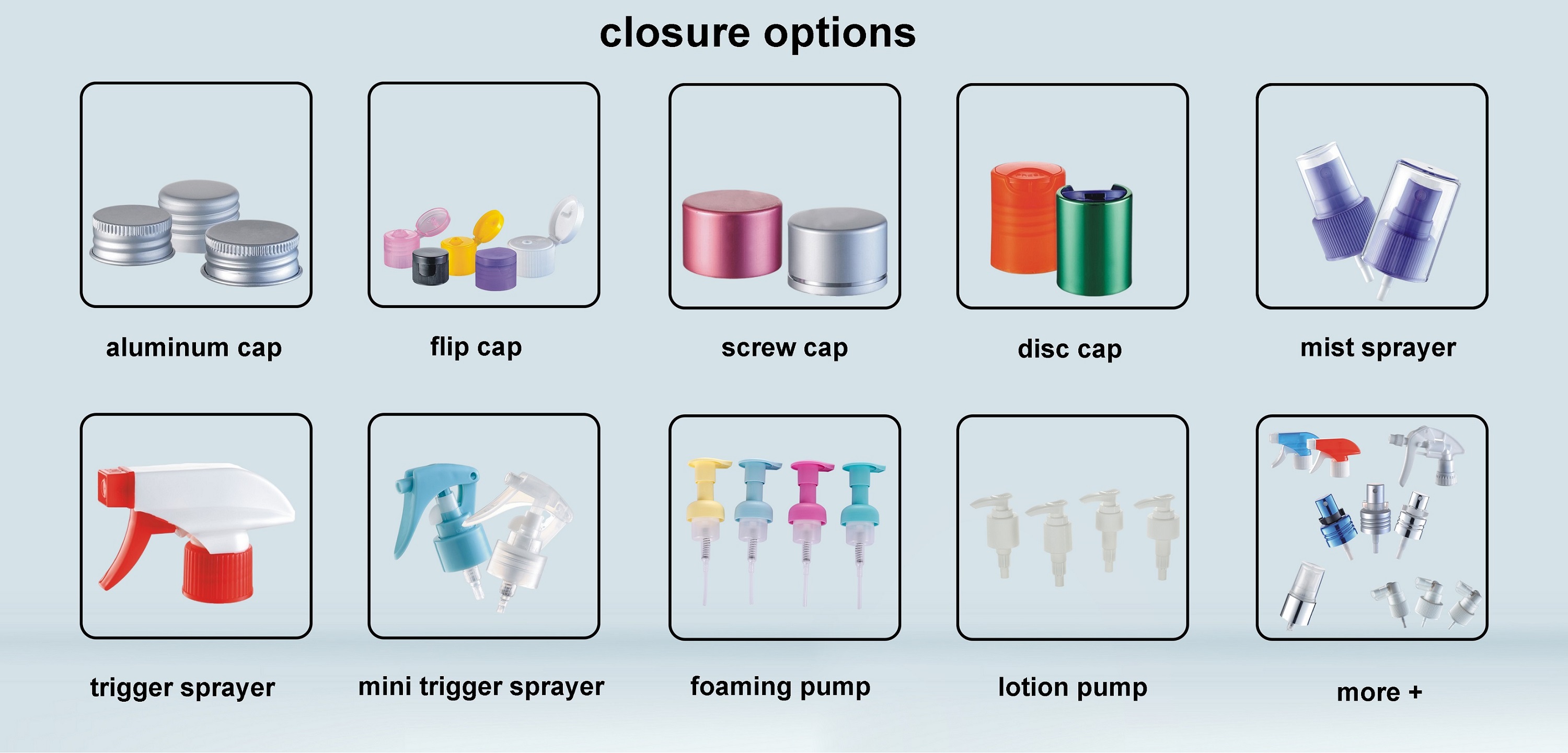

Closure options for the hdpe detergent bottle

Shipment Options of detergent bottle

FAQ

1. Can you produce items which I can't find on your website?

Yes, we are very pleased to design special package for you.

2. What kind of company Xinyi Packaging is?

Xinyi Packaging is a professional cosmetic packaging solution company located in Guangdong, China. Our major products includes PE, PP, PETG bottles, cosmetic tubes, roll on bottle, cream jar, acrylic series,printing materials and so on.

3.Can I get some samples before place order and how long for a sample?

Yes, and sample are always free, Delivery time 7 days.

If customized samples, Cost are various according to your art work. 7-15 days for pre-production sample.

4. How long can I expect to receive my goods after I place order?

Our production time are always 10-25 days after pre- production sample confirmation.

5. What’s your packing method?

We provide standard export carton packing to make sure safety delivery.

We also accept the special packing method according to customer’s design.

6.What’s the payment?

We accept payment as the following,

30% T/T deposit, 70% balance before delivery.

30% TT deposit, the balance L/C

100% TT in advance

Western Union

Paypal for small amount payment.

7. How do you control the quality?

We will make samples before mass production and test them. After sample approved, we will begin mass production.

Doing 100% inspection during production; then do random inspection before packing; taking pictures after packing.