Seamless steel Gas Cylinder

50 liter industrial gas cylinders can meet the needs of gas use for a certain period of time, but not too bulky, easy to handle and storage. Secondly, due to its standardized design and manufacturing, the safety in the filling, transportation and use process can be better guaranteed

|

Implementation standard

|

Cylinder Model

and Standard

|

Norminal Working

Pressure(Bar)

|

Hyd.test Pressure

(Bar)

|

Design Wall Thickness

(mm)

|

Material |

Bottom Shape |

Outer Diameter

(mm)

|

Water Capacity

(L)

|

Length(mm) |

Weight(kg) |

| EN ISO9809-1 |

267-V-150bar |

150 |

250 |

6.0 |

37Mn |

Concave |

267 |

50 |

1110 |

52.8 |

| 232-V-200bar |

200 |

300 |

5.5 |

34CrMo4 |

Concave |

232 |

50 |

1435 |

53.0 |

| 232-V-230bar |

230 |

345 |

5.7 |

34CrMo4 |

Concave |

232 |

50 |

1435 |

53.0 |

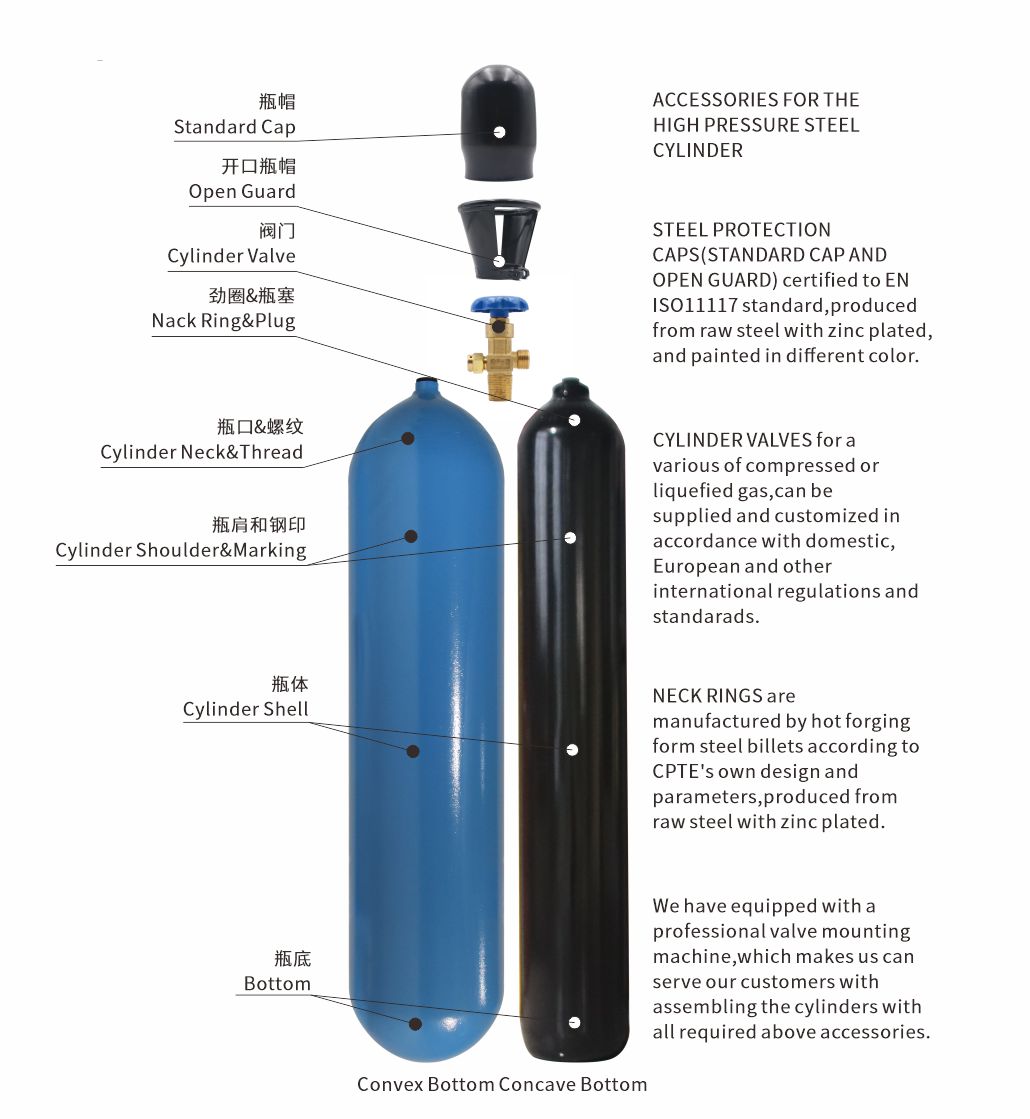

Range of Application:

- Metal processing: such as welding (such as argon arc welding, gas welding, etc.) and cutting (oxygen cutting, etc.), oxygen and acetylene cylinders are often used for this.

- Machinery manufacturing: Used for all kinds of machinery assembly, maintenance process of pneumatic tool drive.

- Chemical industry: as a reaction raw gas storage and supply, such as nitrogen for inert protection, hydrogen for some chemical reactions, etc.

- Electronics industry: High purity gas cylinders are used in semiconductor manufacturing, cleaning, etching and other processes in the production of electronic components.

- Medical field: such as oxygen cylinders for medical emergency and treatment.

- Scientific research experiments: Provide specific gases for various scientific research and experiments.

- Aerospace: Used in the manufacture and inspection of spacecraft, etc.

- Automobile manufacturing: It is also used in the production and maintenance of automobiles.

- Fire protection: Some fire suppression systems use specific cylinders

Why Choose Us?

- Strong production capacity:With a self-built factory covering over 56,000 square meters and employing over 240 staff, the company has the capacity to produce 300,000

- Direct sales from the source factory:By eliminating foreign trade companies, purchasers can directly access the manufacturer for one-stop procurement

- 10 years of industry experience:The factory holds IATF 16949 and ISO 9001 quality management system certificates,

- Customization capability:Our products can be customized according to your preferences, including color, size, thread, and logo.

- At present, the company has 6 gas cylinder spinning production lines, 3 heat treatment and tempering lines, 2 automatic production lines for machine adding, spraying and winding, and 1 LPG composite gas cylinder production line

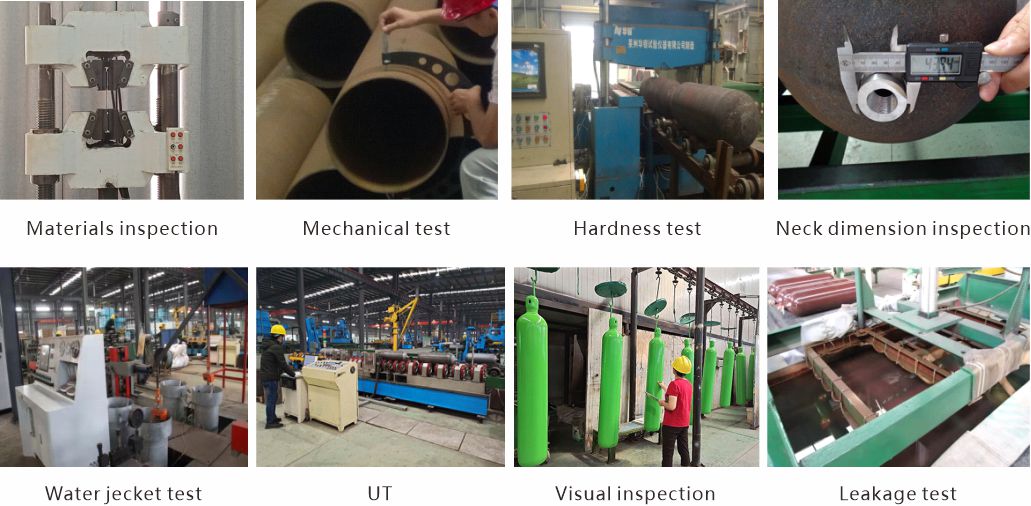

Cylinder Product Inspection Display

After many cylinder tests, the factory ensures that the product is safe and reliable, so that you can buy with confidence and use with confidence. Every inspection procedure is scientifically rigorous and allows no oversight. From the selection of materials to the production process, industrial gas cylinders strive to combine exceptional quality with impeccable safety. Every link demonstrates superb craftsmanship and quality assurance.

Quality Control

Our products have ISO 11439, ISO11119, ISO9089, UN ISO9809, ECE R110, EN11245 and other international certificates, as well as the company's own ISO9001 and IATF 16949 and other international quality system certificates. We know that you want to keep improving the quality of your products. We, on the other hand, focus on details, on quality. Because we believe that every smallest step affects the value and quality of the final product.

Since its establishment over ten years ago, the company has a self-built factory covering an area of 56,000 square meters. We currently have a workforce of 240 employees, including 50 senior technical and management personnel. Additionally, we possess the production capacity to manufacture 300,000 various types of gas cylinders per year, as well as 9,000 sets of CNG framework assemblies and gas supply systems.