Mold Thermostat

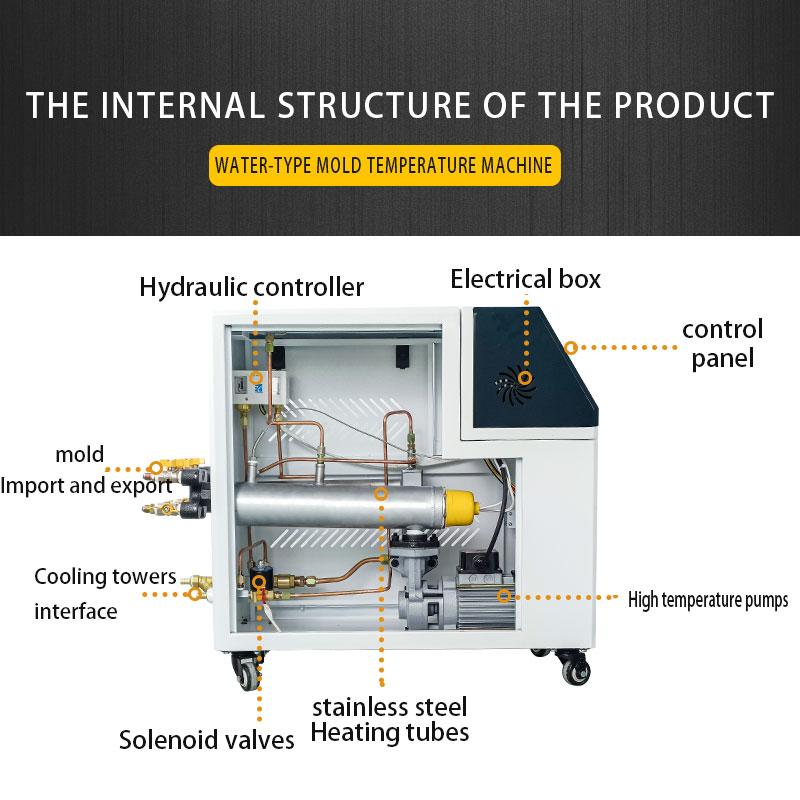

As a kind of precision temperature control equipment, the core function of the mold temperature machine is to be able to accurately adjust the temperature of the mold to ensure the constant temperature environment required in the production process. It consists of several key components, including a heating barrel, a heating and cooling system, a power transmission system, a level control system, as well as a temperature sensor, an injection port, and more.

During the operation, a pump in the power transmission system transports the hot fluid from the tank with the built-in heater and cooler to the mold and back from the mold to the tank. The temperature sensor monitors the temperature of the hot fluid in real time and transmits the data to the controller in the control section. The controller automatically adjusts the state of the heater and solenoid valve according to the set target temperature value, so as to indirectly control the temperature of the mold.

When the mold temperature exceeds the set value, the controller will open the solenoid valve and let the cooling water into the system to reduce the temperature of the hot fluid until it returns to the preset range. Conversely, if the mold temperature drops below the set point, the controller activates the heater to increase the temperature of the hot fluid so that the mold temperature reaches the desired level.

This fine temperature adjustment mechanism ensures that the mold can maintain the best and constant temperature state in the production process, effectively avoids the product quality problems caused by temperature fluctuations, and greatly improves the production efficiency and product yield.

Key Features:

1. Exclusive Customization:

We will tailor different KW water/oil mold thermostats for you according to the needs of customers, and the price required for different power will be different.

2.. Precise temperature control

The mold thermostat adopts advanced temperature monitoring and feedback system, which can realize the precise control of mold temperature, ensure that the mold is in the best temperature environment during the production process, and greatly improve the product quality consistency.

3. Energy efficient

The unique heating and cooling design makes full use of the heat circulation, greatly reduces energy consumption, saves more than 30% of energy consumption compared with traditional methods, and realizes more environmentally friendly and energy-saving production.

4. Easy to operate

The user-friendly control interface design is simple and easy to use, even non-professionals can quickly master the use skills, which greatly improves the applicability and efficiency of the equipment.

5. Stable and reliable

The use of high-quality core components, with intelligent monitoring system, to ensure the long-term stable operation of the equipment, minimize the risk of failure and downtime losses, and create greater value for users.

6. Widely applicable

Whether it is injection molding, die-casting or other thermoforming processes, the mold thermostat is capable of meeting the temperature control needs of different industries and materials, and has strong applicability.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.