Dual-temperature mold temperature machine

Water/oil temperature machine is an advanced temperature regulating equipment, which is widely used in mold temperature control in many industries such as plastics, rubber, metal, etc. With a power of 9KW, the temperature can be adjusted quickly and efficiently to the desired range, ensuring that the mold maintains a constant temperature environment during the production process.

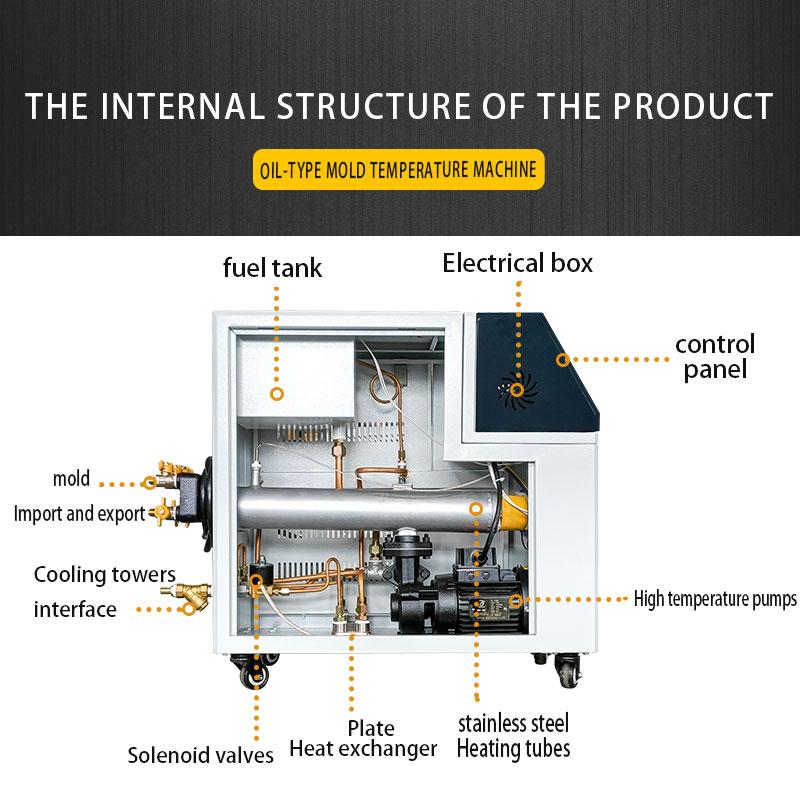

The core components of this water/oil temperature machine include a heating unit, a cooling system, a liquid circulation system and an intelligent control system. The heating unit uses a high-power electric heating tube to quickly increase the temperature of the liquid. The cooling system uses water-cooled or air-cooled technology to quickly cool down and ensure that the temperature fluctuates within ±0.5°C. The liquid circulation system circulates temperature-controlled liquid to the mold by a high-efficiency pump to achieve uniform heating/cooling. The intelligent control system accurately monitors the temperature data and automatically adjusts the heating and cooling states to ensure that the mold temperature is always stable at the set value.

In addition, the temperature machine has a user-friendly design and the control panel is simple and intuitive to operate. Key parameters such as temperature and flow are clear at a glance and can be easily set and adjusted by the user. Built-in multi-level safety protection devices, such as over-temperature, water shortage, leakage, etc., effectively prevent various risks in operation. Rugged body for durability and extreme reliability.

With excellent temperature control performance and user-friendly design, the 9KW water/oil temperature machine is widely praised. It can not only ensure the stability and reliability of product quality, but also greatly improve production efficiency and effectively reduce the production cost of enterprises. Whether it's plastic injection molding, rubber vulcanization or metal die casting, this temperature machine is the ideal choice.

Key Features:

1. Exclusive Customization:

We will tailor different KW water/oil mold thermostats for you according to the needs of customers, and the price required for different power will be different.

2. Dual temperature independent control

The dual-temperature mold temperature machine is equipped with an independent heating and cooling system, which can accurately adjust the high and low temperature zones of the mold at the same time to meet diverse temperature requirements.

3. Energy efficient

Advanced heat recovery technology recycles heat between heating and cooling systems, significantly reducing energy consumption and achieving more environmentally friendly and energy-saving production.

4. Intelligent temperature management

The intelligent control system based on IoT technology can monitor temperature changes in real time and automatically adjust them to ensure that the mold temperature is always stable within the optimal range.

5. Easy to operate

The humanized touch screen control interface is intuitive, intuitive and clear, and the operation is simple and easy to use, which greatly improves the efficiency of equipment use.

6. Widely applicable

Whether it's injection molding, die casting, or other thermoforming processes, this dual-temperature mold temperature controller offers customized solutions to meet the temperature control needs of a wide range of industries.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.