ALLEN BRADLEY 1746-HS SER A MOTION CONTROL MODULE (IN STOCK&READY FOR SHIP)

Contact: Miya

Contact: Miya

Job Title: Sales Manager

Job Title: Sales Manager

Skype: live:miyazheng520

Skype: live:miyazheng520

Email: sales@amikon.cn

Email: sales@amikon.cn

Tel: 86-18020776792(Whats App )

Tel: 86-18020776792(Whats App )

QQ :2851195450

QQ :2851195450

Brand Name AB

Product reference 1746-HS

The Allen-Bradley 1746-HS is a SLC 500 IMC 110 Motion Control System. This IMC 110 Motion Control System has 24 Volts DC Inputs and 24 Volts DC Outputs with a Backplane Current (24 Volts) of 104 milliamps.

The Allen Bradley 1746-HS is an IMC 110 Motion Control Module for an SLC 500 system. It has 24 Volts of DC Inputs and Outputs with a Backplane Current of 300 mA at 5 Volts DC and 104 mA at 24 Volts DC. With an input frequency of 300 kHz and a 4.8 millisecond update time, its step response is 100 milliseconds for input and 2.5 milliseconds for output. It requires one slot for installation in an SLC 500 system chassis and is compatible with all SLC processors except SLC 5/01 and SLC 5/02 processors. Depending on the application for incremental, absolute or speed moves, the 1746-HS can be programmable.

The 1746-HS Motion Control Module uses an Offline Development System (ODS) that allows a user to utilize a compatible computer to create, edit, and document Adjustable Machine Parameters (AMP) and Motion Management language (MML) files. For communication, it uses an RS-485 port to directly download AMP and MML files. It also supports the restoration of backed-up projects for later use.

The 1746-HS module constantly uses I/O updates to keep the SLC informed of its working process. It must be as close to the SLC processor as possible for better functionality and is intended for use in a clean and dry environment. This unit operates at a temperature between 0 and 60 degrees Celsius and has a 30 g operating shock.

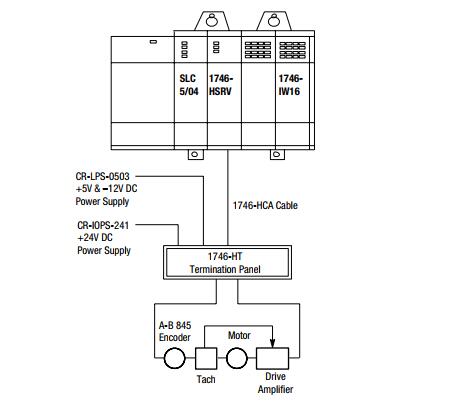

The SLC Servo Module (catalog number 1746-HSRV) is compatible

with the SLC 500 family and only used with SLC 5/03™ FRN 5.0, SLC

5/04™, or SLC 5/05™ SLC Servo Modules. The SLC Servo Module is

programmed for incremental, absolute or speed moves, depending on

the application.

The SLC Servo Module, compatible with the SLC family, is used with

SLC 5/03 FRN 5.0 (and above) processors using RSLogix 500, AI500 or

APS (version 5.0 or higher) software. Once the SLC processor is

initiated, the execution of the motion block is independent of the scan

time of the processor. Blended motion allows for complicated move

profiles consisting of two to thirty-two segments. The blended move

profiles are stored in the SLC Servo Module’s memory as a series of

absolute moves and can be executed more than once. Other move or

homing operations can be performed between blended move profiles.

The SLC Servo Module controls absolute position over a range of 32

bits. The SLC Servo Module performs an origin search (also called

homing) and automatically resets the absolute position to the home

position when the SLC processor requests a search function after

detecting one of the following:

• Encoder marker

• Limit switch

• Limit switch and marker

The SLC Servo Module operates in two modes:

• Configuration

• Command

When operating in the configuration or the command mode, the status

of the module is reported to the SLC processor.

Configuration Mode Operation

You can enter configuration mode only if the system is in Estop. In the

SLC Servo Module, you configure the SLC Servo Module by using M

files containing data provided by the SLC 5/03 (or versions listed

above) processors. All configuration parameters are internal to the SLC

Servo Module and stored in non-battery backed RAM.

In configuration mode, you select the proper setup configuration to

match the servo drive and motor without setting switches and without

special software. If you do not set up your own configuration, the

configuration is set to the default setting.

Command Mode Operation

Motor operations are performed in command mode. To operate in this

mode, set the mode flag (bit 15 in output word 0) to 0. In the

command mode, the SLC processor issues commands and activates

the following operations or moves:

• Absolute moves

• Incremental moves

• Speed moves

• Monitor moves

• Hold moves

• Unhold moves

• Blend moves

• Emergency stop operations

• Homing operations

• Preset operations

• Clear faults

• Alternate home moves

Related Product

|

FOXBORO

|

FBM207C

|

|

FOXBORO

|

P0961BS-OC

|

|

FOXBORO

|

FBM239 P0927AG

|

|

FOXBORO

|

FBM231

|

|

FOXBORO

|

FBM206

|

|

FOXBORO

|

FBM203

|

|

FOXBORO

|

FBM206 P0916CQ

|

|

FOXBORO

|

PF3S-PSA1

|

|

FOXBORO

|

PF3S-BP13

|

|

FOXBORO

|

FBM217

|

|

FOXBORO

|

BO123HE

|

|

FOXBORO

|

P0914XB

|

|

FOXBORO

|

FBM214

|

|

FOXBORO

|

CP40B

|

|

FOXBORO

|

CP40

|

|

FOXBORO

|

CP60

|

|

FOXBORO

|

CP30

|

|

FOXBORO

|

IPM2-P0904HA

|

|

FOXBORO

|

P0916AE

|

|

FOXBORO

|

FBI10E

|

|

FOXBORO

|

CP30B

|

|

FOXBORO

|

FBM201

|

|

FOXBORO

|

FCP270 P0917YZ

|

|

FOXBORO

|

P0931RQ

|

|

FOXBORO

|

P0931RM

|

|

FOXBORO

|

P0917MF

|

|

FOXBORO

|

P0916CC

|

|

FOXBORO

|

P0903CW

|

|

FOXBORO

|

FBM214b P0927AH

|

|

GE

|

DS200SDCIG2AFB

|

|

GE

|

531X305NTBACG1

|

|

GE

|

531X113PSFARG1

|

|

GE

|

531X111PSHAPG3

|

|

GE

|

IC697CPM790

|

|

GE

|

DS200LDCCH1 DS200LDCCH1ALA

|

|

GE

|

IC695CRU320/IC695CRU320CA-EL

|

|

GE

|

IC693CPU374-KZ

|

|

GE

|

IC695CPU315

|

|

GE

|

IC693ALG392

|

|

GE

|

IC697CPX935

|

|

GE

|

IC694MDL740

|

|

GE

|

IC693MDL740F

|

|

GE

|

IC693MDL740

|

|

GE

|

IC200MDL740

|

|

GE

|

IC200ALG630

|

|

GE

|

IC200ALG322

|

|

GE

|

DS200PCCAG9ACB

|

|

GE

|

531X303MCPBCG1

|

|

GE

|

IC670MDL740

|

|

GE

|

IC694MDL753

|

|

GE

|

IC694BEM331

|

|

GE

|

IC694APU300

|

|

GE

|

IC693PCM301

|

|

GE

|

IC693MDL752

|

|

GE

|

IC693MDL646

|

|

GE

|

IC693MDL330

|

|

GE

|

IC693ALG390

|

|

GE

|

IC693ACC310

|

|

GE

|

IC693MDL645

|

|

GE

|

IC693BEM331

|

|

GE

|

IC693MDL930

|

|

GE

|

IC693PWR321P

|

|

GE

|

IC693PWR330

|

|

GE

|

IC693MDL741C

|

|

GE

|

IC695CPU320

|

|

GE

|

IC693DSM302

|

|

GE

|

IC693CPU372

|

|

GE

|

IC693CPU350

|

|

GE

|

IC200CPU002

|

|

GE

|

IC200ALG264

|

|

GE

|

HE693PBS105

|

|

GE

|

IC693ALG223

|

|

GE

|

IC693CPU311

|

|

GE

|

IC200CPUE05

|

Our Advantages:

1.365 days warranty for all the goods from us.

2.2000+ suppliers with us, we could help you to get any components which is difficult to get.

3.Risk-free guarantee, 60 days refund. If the item you purchase from our store are not of perfected quality, simply return them to us for replacement or refund.

|

If you have any question pls do not hesitate to contact us.We can supply all kind of the

automation parts,if you want to purchase

parts pls send the parts model to my mail, I will prompt reply you as I receive the mail.Hope anyone inquire from us.

Waiting for your inquiry.

|