Allen Bradley 1785-LT3 Processor Module

Contact: Miya

Contact: Miya

Job Title: Sales Manager

Job Title: Sales Manager

Skype: live:miyazheng520

Skype: live:miyazheng520

Email: sales@amikon.cn

Email: sales@amikon.cn

Tel: 86-18020776792(Whats App )

Tel: 86-18020776792(Whats App )

QQ :2851195450

QQ :2851195450

Brand Name AB

Product reference 1785-LT3

Classic PLC�5 Family Processor Features

From the family of PLC-5 processors, you can choose the processor(s)

that you need for your application. Features common to all Classic PLC-5

processors are:

same physical dimensions

use of the left-most slot in the 1771 I/O chassis

can use any 1771 I/O module in the processor-resident local I/O chassis

with up to 32 points per module

same programming software and programming terminals

same base set of instructions

ladder programs and SFCs can be used by any of the PLC-5 processors

Check with your Allen-Bradley sales office or distributor if you have

questions regarding any of the features of your PLC-5 processor.

Subprogram Calls

Use a subroutine to store recurring sections of program logic that can be

accessed from multiple program files. A subroutine saves memory

because you program repetitive logic only once. The JSR instruction

directs the processor to go to a separate subroutine file within the logic

processor, scan that subroutine file once, and return to the point

of departure.

For detailed information about how you generate and use subroutines, see

your programming software documentation set.

Sequential Function Charts

Use SFCs as a sequence-control language to control and display the state

of a control process. Instead of one long ladder program for your

application, divide the logic into steps and transitions. A step corresponds

to a control task; a transition corresponds to a condition that must occur

before the programmable controller can perform the next control task. The

display of these steps and transitions lets you see what state the machine

process is in at a given time.

For detailed information about how you generate and use SFCs, see you

programming software.

Ladder Logic Programs

A main program file can be an SFC file numbered 1-999; it can also be a

ladder-logic file program numbered 2-999 in any program file.

Backup System

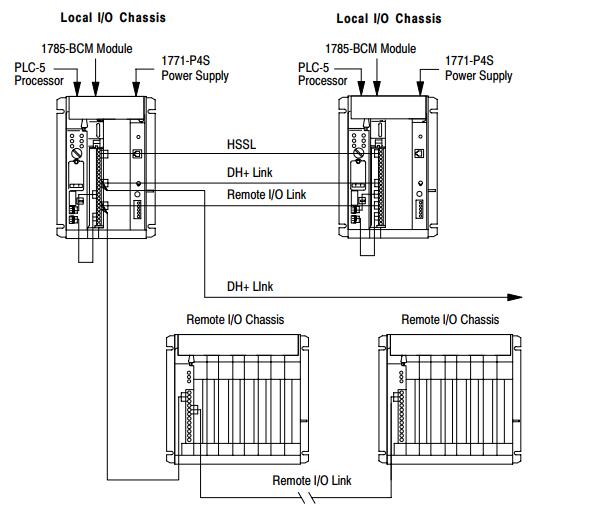

The following diagram shows a typical PLC-5 backup system:

In a PLC-5 backup system configuration, one system controls the operation

of remote I/O and DH+ communications. This system is referred to as the

“primary system.” The other system is ready to take control of the remote

I/O and DH+ communications in the event of a fault in the primary system.

This is referred to as the “secondary system.”

See chapter 2, “Choosing Hardware,” to select backup system hardware.

See the PLC-5 Backup Communication Module User Manual, publication

1785-6.5.4, for more information on configuring a PLC-5 backup system.

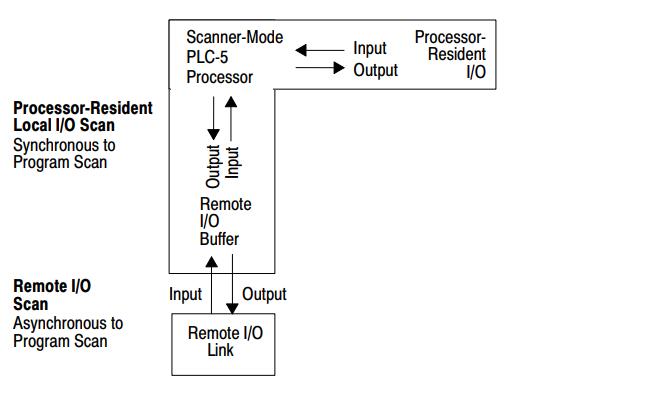

Use scanner mode whenever you want a Classic PLC-5 processor to scan

and control remote I/O link(s). The scanner-mode processor also acts as a

supervisory processor for other processors that are in adapter mode.

The scanner-mode processor scans the processor memory file to read

inputs and control outputs. The scanner-mode processor transfers

discrete-transfer data and block-transfer data to/from the processor-resident

local rack as well as to/from modules in remote I/O racks.

A PLC-5 processor scans processor-resident local I/O synchronously to the

program scan. A PLC-5 processor scans remote I/O asynchronously to the

program scan, but the processor updates the input/output image data table

from the remote I/O buffer(s) synchronously to the program scan. This

occurs at the end of each program scan.

The scanner-mode PLC-5 processor can also:

gather data from node adapter devices in remote I/O racks

process I/O data from 8-, 16-, or 32-point I/O modules

address I/O in 2-, 1-, or 1/2-slot I/O groups

support a complementary I/O configuration

support block transfer in any I/O chassis

Configure the PLC-5/15 or -5/25 processor for scanner mode by setting

switch assembly SW1.

Use a Classic PLC-5 processor (except the PLC-5/10 processor) in adapter

mode when you need predictable, real-time exchange of data between a

distributed control PLC-5 processor and a supervisory processor. You

connect the processors via the remote I/O link (see Figure 1.3). You can

monitor status between the supervisory processor and the adapter-mode

PLC-5 processor at a consistent rate (i.e., the transmission rate of the

remote I/O link is unaffected by programming terminals and other

non-control-related communications).

1 The following programmable controllers can operate as supervisory processors:

PLC�2/20� and PLC�2/30� processors

PLC�3� and PLC�3/10� processors

PLC�5/11, �5/15, �5/20, �5/25, and �5/30 processors as well as PLC�5/VME� processors

PLC�5/40, �5/40L, �5/60, �5/60L, and �5/80 processors as well as PLC�5/40BV� and

PLC�5/40LV� processors

PLC�5/20E�, �5/40E�

PLC�5/250�

All PLC�5 family processors, except the PLC�5/10, can operate as remote I/O adapter modules.

2

2

The PLC-5 processor in adapter mode acts as a remote station to the

supervisory processor. The adapter-mode PLC-5 processor can monitor

and control its processor-resident local I/O while communicating with the

supervisory processor via a remote I/O link.

The supervisory processor communicates with the PLC-5/12, -5/15, or

-5/25 adapter with either eight or four I/O image table words.

A PLC-5 processor transfers I/O data and status data using discrete

transfers and block transfers. You can also use block-transfer instructions

to communicate information between a supervisory processor and an

adapter-mode processor. The maximum capacity per block transfer is

64 words.

OTHER RECOMMENDATION

|

GE

|

DS200SDCIG2AFB

|

|

GE

|

531X305NTBACG1

|

|

GE

|

531X113PSFARG1

|

|

GE

|

531X111PSHAPG3

|

|

GE

|

IC697CPM790

|

|

GE

|

DS200LDCCH1 DS200LDCCH1ALA

|

|

GE

|

IC695CRU320/IC695CRU320CA-EL

|

|

GE

|

IC693CPU374-KZ

|

|

GE

|

IC695CPU315

|

|

GE

|

IC693ALG392

|

|

GE

|

IC697CPX935

|

|

GE

|

IC694MDL740

|

|

GE

|

IC693MDL740F

|

|

GE

|

IC693MDL740

|

|

GE

|

IC200MDL740

|

|

GE

|

IC200ALG630

|

|

GE

|

IC200ALG322

|

|

GE

|

DS200PCCAG9ACB

|

|

GE

|

531X303MCPBCG1

|

|

GE

|

IC670MDL740

|

|

GE

|

IC694MDL753

|

|

GE

|

IC694BEM331

|

|

GE

|

IC694APU300

|

|

GE

|

IC693PCM301

|

|

|

|

BENTLY NEVADA

|

3500/15 AC 127610-01

|

|

BENTLY NEVADA

|

3500/72M 176449-08

|

|

BENTLY NEVADA

|

3500/32M 149986-02

|

|

BENTLY NEVADA

|

3500/53 133388-01

|

|

BENTLY NEVADA

|

125388-01

|

|

BENTLY NEVADA

|

128275-01

|

|

BENTLY NEVADA

|

330180-X1-CN

|

|

BENTLY NEVADA

|

3300/46-46-04-02-01

|

|

BENTLY NEVADA

|

3300/20-13-03-01-00-00

|

|

BENTLY NEVADA

|

330780-91-00

|

|

BENTLY NEVADA

|

330103-00-04-10-02-05

|

|

BENTLY NEVADA

|

330130-040-01-00

|

|

BENTLY NEVADA

|

330130-080-02-05

|

|

BENTLY NEVADA

|

172109-01

|

|

BENTLY NEVADA

|

330103-00-05-10-02-00

|

|

BENTLY NEVADA

|

330703-000-060-10-02-00

|

|

BENTLY NEVADA

|

330103-00-10-10-02-00

|

|

BENTLY NEVADA

|

330103-00-06-10-02-00

|

|

BENTLY NEVADA

|

330730-080-00-00

|

|

BENTLY NEVADA

|

172103-01

|

|

BENTLY NEVADA

|

3500/22M

|

|

BENTLY NEVADA

|

330105-02-12-90-02-05

|

|

BENTLY NEVADA

|

3500/64M

|

|

BENTLY NEVADA

|

3500/44M

|

|

BENTLY NEVADA

|

5300-08-050-03-00

|

|

BENTLY NEVADA

|

330878-90-00

|

|

BENTLY NEVADA

|

330103-10-14-10-02-CN

|

Our Advantages:

1.365 days warranty for all the goods from us.

2.2000+ suppliers with us, we could help you to get any components which is difficult to get.

3.Risk-free guarantee, 60 days refund. If the item you purchase from our store are not of perfected quality, simply return them to us for replacement or refund.

|

If you have any question pls do not hesitate to contact us.We can supply all kind of the

automation parts,if you want to purchase

parts pls send the parts model to my mail, I will prompt reply you as I receive the mail.Hope anyone inquire from us.

Waiting for your inquiry.

|