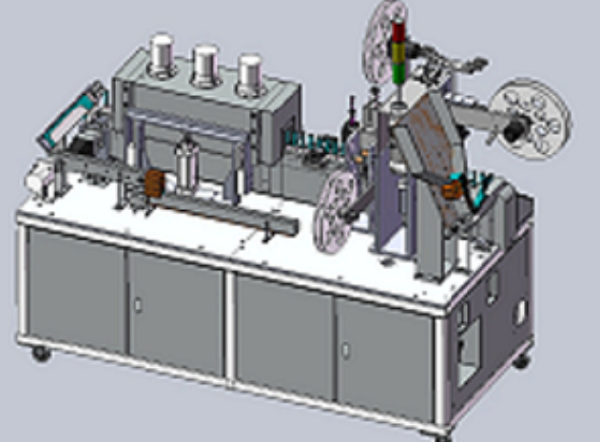

Automatic 18650 Cylindrical Battery Pack Heat Wrapper Shrinking Machine for PP/PVC/POF Material

FEATURE

The cylinder battery laminating machine is a kind of automatic equipment which is used for laminating of cylinder battery, punching and placing insulating gasket and heat shrinkable standard. This equipment can pack about 3300 electric cores per hour, and the structure design is simple and generous, and the performance is stable. In the market, up to now, it is one of the most cost-effective integrated standard equipment

1. High efficiency: the film efficiency is 50~70PCS/MIN. It is 6~10 times of artificial efficiency

2. High precision: the precision servo motor and high-precision mechanical structure make the film precision up to ±0.1MM, and the technology is leading the industry.

3. Highly intelligent: the humanized operation interface is convenient for manual operation, the fault is automatically alarmed, and the fault point is clear at a glance;

4. Simple operation and maintenance: the personnel can operate the equipment with a little training, and the maintenance is relatively simple;

5. High flexibility of equipment: After replacing the fixture and mold, it can be adapted to cylindrical batteries such as AA, AAA and 18650.

Technological process

The parameter setting is completed through the touch screen, and the following functions are automatically completed by PLC: manual loading of battery core→ feeding by motor + cylinder → battery delivery by chain → battery core correction + servo labeling → laminating surface pad → correction again → spinning feeding + tunnel furnace heat shrinking → the first turning of air cylinder → loading by belt running → the second turning of air cylinder (feeding groove of finished battery core) → feeding and discharging groove; equipment allocation Sound light alarm is set.

Operation parameters can be set according to the actual requirements

Structure

1) The structure of the equipment is compact and reasonable, the appearance is beautiful, and the occupied space is small.

2) The equipment is easy to operate, and workers can easily master it without professional training.

3) The equipment is controlled by PLC, which is responsible for battery feeding, labeling, laminating surface pad, heat shrinkable insulation skin, easy to learn, high efficiency, labor cost saving, and good product performance.

4) The equipment and materials are made of high-quality thick cold-rolled sheet metal and aluminum profile frame.

5) The equipment is equipped with universal casters, which makes it easy to move and handle the equipment.

Specification

|

Model

|

Tmax-Shrinking

|

|

Specification

|

AA,AAA,18650

|

|

Film speed

|

50~70PCS/MIN

|

|

Film precision

|

±0.1MM

|

|

Power supply

|

380V/220V

|

|

Air pressure

|

0.5~0.7Mpa

|

|

Power

|

9KW

|

|

Weight

|

800KG

|

|

Machine size

|

2100(L)*950(W)*1600(H)

|

|

Casing requirements

|

The width of the coil is 29.7±0.2mm, and the thickness of the single layer is 0.08±0.01mm.

|

|

Insulation sheet coil size

|

width between 20 ± 0.1mm (no material break and tape interface in the middle of the coil)

|

|

Insulation sheet die size

|

Outer diameter 17.4 ± 0.1 mm; inner diameter 10.5 ± 0.1 mm; inner and outer diameter concentricity ± 0.10 mm

|

|

Heat shrinkable bottom edge size

|

2.5mm ± 0.3mm (size error is related to casing material and baking conditions)

|

Product Images

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.