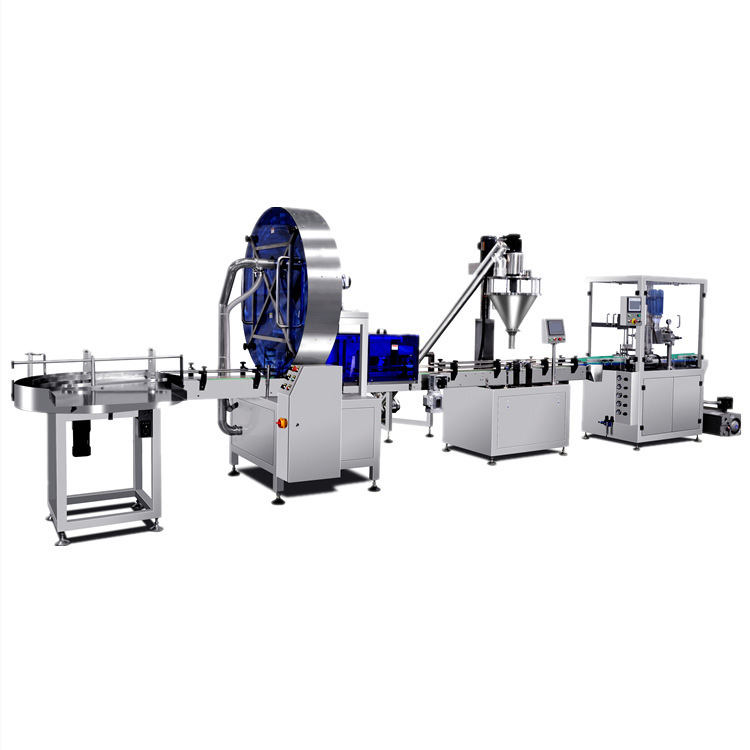

Automatic 850g Milk Powder Coffee Packing Machine Can Filling Line Machine

Layout: Automatic 850g Protein Powder Filling Capping Line

Flow Chart--Automatic Powder Multi-Function Production Line:

Step 1: the unscrambler will unscramble and lined up the cans first

Step 2: the UV sterilizer sterilize the cans before powder filling

Step 3: the powder screw feeder lift the powder from hopper to the tube top, then drop the powder

Step 4: the powder auger filling machine will fill the powder into the cans

Step 5: the automatic cans seamer (vacuum nitrogen function is optional) will seal cans one by one

Step 6: the cans cleaning machine polish and clean cans body after canning

Step 7: the date coding machine code the date on bottom

Step 8: the snap lid applicator press the plastic lid on the cans

Step 9: the unscrambler will collect all the cans at the end

Advantages--Automatic Can Packing Line:

1. Automatically material conveying, weighing, canning, labeling to elimilate the unnecessary labor cost and promote production efficiency at the same time.

2. Advanced Tech: Human-Computer Interaction Touch Screen, PLC Controller, Photoelectricity Senser, High Accuracy Servo Motor etc.

3. Auxiliary device: like nitrogen gas generator or liquid nitrogen storage tank and other device could be assemble together depend on your request.

4. Application: it is suitable for paper/plastic/metal cans packing and widely used in food, pharmaceutical, chemical, commodity industries etc.

Specification--Powder Auger Doser For Food Powder:

Hopper capacity

|

15L

|

30L

|

50L

|

100L

|

Measuring range

|

0.5-200g

|

10-500g

|

50-5000g

|

5000-25000g

|

measuring accuracy

|

1%

|

1%

|

0.5%-1%

|

0.5%

|

Filling speed

|

30-100

|

30-120

|

30-120

|

5-15

|

Filling machine Power

|

1kw

|

1.2kw

|

1.9kw

|

2.75kw

|

Weight

|

30kg

|

40kg

|

60kg

|

100kg

|

Applications--Automatic Whey Powder Filling Line

Contact Us