The product description

This die-casting machine reduces the drying cycle time by more than 15%;Increase pump flow by more than 20%;Increase refrigeration capacity by more than 100%;Qualified rate increased by 100%;Productivity is 20% higher than in the past.

Product parameters

LH series of standard parameter table (170 t)

|

ITEMS

|

Unit

|

Specification

|

|

HYDRAULIC WORKING PRESSURE

|

MPa

|

7

|

|

CLAMPING FORCE

|

KN

|

1700

|

|

SPACE BETWEEN TIE BARS

|

mm

|

460*460

|

|

Tie Bar Diameter

|

mm

|

80

|

|

DIE OPENING STROKE

|

mm

|

350

|

|

INJECTION FORCE(intensify)

|

KN

|

220

|

Plunger launch distance

|

mm

|

120

|

|

Injectionposition

|

mm

|

0 -- 140

|

|

PLUNGER DIAMETER

|

mm

|

40----60

|

|

INJECTION STROKE

|

mm

|

320

|

Casting pressure (intensify)

|

MPa

|

143/92/64

|

Casting Fiange Protrusion

|

mm

|

10

|

Casting Fiange Diameter

|

mm

|

110

|

|

MAX CASTING AREA UNDER 40Mpa

|

CM2

|

400

|

|

lnjection Weight(Al)

|

Kg

|

1.8

|

|

Die Height(Min--Max)

|

mm

|

200~550

|

|

EJECTOR FORCE

|

KN

|

100

|

|

EJECTOR STROKE

|

mm

|

80

|

|

Motor Capacity

|

Kw

|

11

|

|

Machine Dimensions (L*W*H)

|

m

|

5.5*1.6*2.05

|

|

Referential Machine Weight For Uplifting

|

T

|

5.8

|

|

Oil Tank Capacity

|

L

|

300

|

We reserve the right to make any technical improvement without further notice

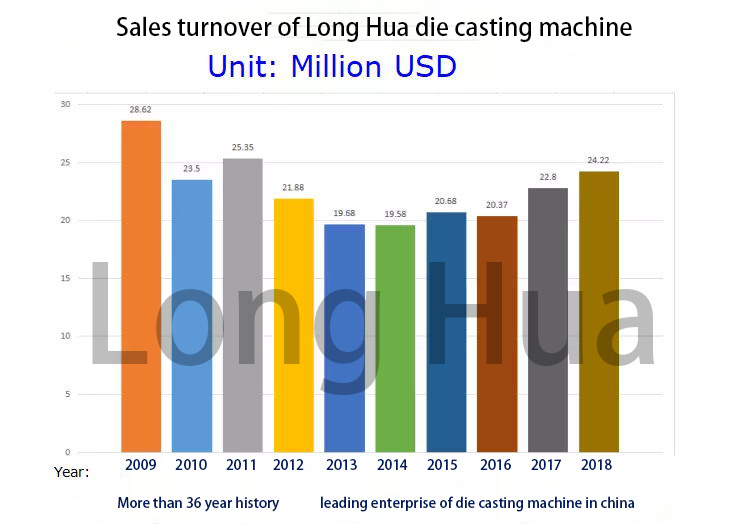

sales turnover

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.