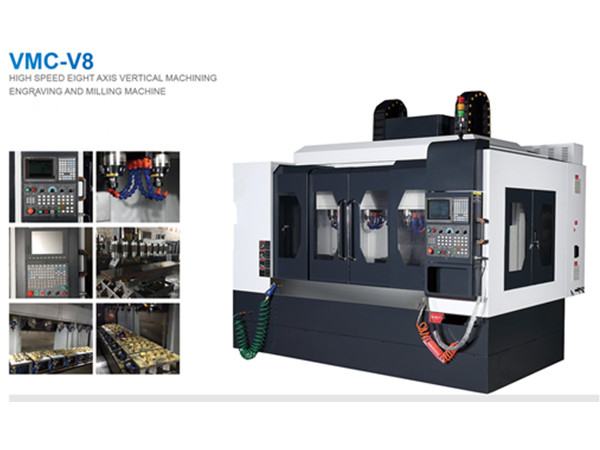

Automatic Faucet Grinding Machine

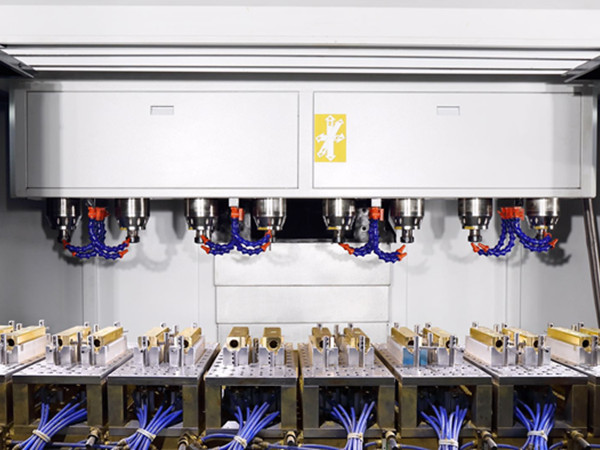

The spindle system of machine tool are used for constant torque and high speed electric spindle,the maximum speed of 18000rpm,the important parts are by strengthening treatment,and adopt the world famous brand NSKP4 special bearings for spindle and use high-quality high-temperature grease for it,whole spindle assembled in constant temperature conditions,through the computer balance correction and running test,it make the whole spindle use long life,high precision,strong reliability.

|

Model No.VMC-V8

|

|

X-axis (left and right stroke): 420mm

|

|

Y axis (front and back stroke): 530mm

|

|

Z axis (up and down stroke): 500mm

|

|

Spindle center to column guide rail distance: 550mm

|

|

Spindle end to table surface distance: 100-600mm

|

|

Y-axis rail spacing: 700mm

|

|

Working table size: 2100×500mm

|

|

Type T groove: 5×18×102

|

|

Table maximum load weight: 600KG

|

|

Taper hole of spindle: ER32

|

|

Spindle speed: 18000rpm

|

|

Spindle motor: 5.5*8KW

|

|

X-axis motor: 2KW

|

|

Y-axis motor: 2KW

|

|

Z-axis motor: 3KW

|

|

Three-axis maximum cutting feedrate: 10m/min

|

|

Three-axis fast moving: 20m/min

|

|

Positioning accuracy: ±0.04mm

|

|

Repeatability precision: ±0.05mm

|

|

Size: 3000×2300×3000

|

|

Pneumatic power: 6-9kg/cm2

|

|

Power supply capacity : 50KW

|

|

Weight: 7000KG

|

|

Name

|

Brand

|

|

NC system

|

SYNTEC(Taiwan)

|

|

NC system

|

Mitsubishi(Japan)

|

|

Servo variable frequency drive

|

Domestic

|

|

X,Y,Z axis servo motor

|

YASKAWA set(Japan)

|

|

X,Y,Z axis servo motor

|

MITSUBISHI full set(Japan)

|

|

Electric spindle motor

|

Domestic

|

|

Spindle bearing

|

THT/NSK(Japan)

|

|

Screw rod bearing

|

THT/NSK(Japan)

|

|

Linear guide rail

|

YINTAI/SHANGYIN(Taiwan)

|

|

Ball screw

|

YINTAI/SHANGYIN(Taiwan)

|

|

Tool magazine

|

BEUU(Taiwan)

|

|

Coupling

|

Domestic

|

|

Heat exchanger

|

Domestic XIDA

|

|

Compensating cylinder

|

Domestic

|

|

Automatic lubrication system

|

Domestic

|

|

Coolant system

|

Domestic Luokai

|

|

Lighting system

|

Domestic LED

|

|

Alarm lamp

|

Domestic Southern China Tiancheng

|

|

Contactor

|

France Schneider

|

|

Breaker

|

France Schneider

|

|

Spindle oil cooler

|

Domestic

|

|

Electric

|

France Schneider

|

Our Service:

Before sales

Our professional technical recommend the right machine,and can also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical go to customer's factory to install and adjust machine.

We have after-sell service to supply all life-time machine maintance and repairment service.

FAQ:

Q: Are we a trading firm or a manufacturer?

A: We are a MANUFACTURER.

Q: What’s our payment mode?

A: L/C, T/T

Q: Can machines be customized?

A: YES.

Q: How long is the warranty period?

A: 12 months.