Automotiver Rubber Cover Element Black

Rubber cover element black-The first is fluororubber. It is resistant to high temperature, oil, acid and alkali and strong oxidants. Temperatures range from minus 30 degrees Celsius to 260 degrees Celsius. It is mainly used in high temperature, high pressure and vacuum environment, as well as oil environment. They range from aerospace to petrochemical.

The second type of silicone rubber, which can also withstand high temperature and low temperature, can be used in the environment of minus 70 degrees Celsius to 260 degrees Celsius and good elasticity.

Best used for sealing gaskets in thermal machinery. In addition, it is resistant to ozone and aging, and non-toxic, can be used to make insulation, medical rubber products and insulation products.

The third category, nitrile rubber. It is an excellent aromatic solvent and oil resistant, so it can be used to make oil resistant sealing products, but it is not resistant to ketones, chlorinated resins and esters.

The fourth type, neoprene, is well resistant to solvents and chemical media and to oil. It has ozone resistance, oxidation resistance and weathering resistance. In life, it can be made into doors and Windows sealing strip and diaphragm and vacuum sealing products can be seen everywhere.

Fifth, three ethylene propylene, in the door and window sealing strip and the automotive industry is used more, with excellent performance of temperature resistance, oxidation resistance and ozone resistance as well as weathering aging.

The sixth, polytetrafluoroethylene composite gasket. It is a new type of sealing material made of high quality rubber and polytetrafluoroethylene as raw materials, using a special process. With the double excellent characteristics of ptfe and rubber, the product can be made of high temperature resistance, adhesion resistance, and non-toxic corrosion resistance, with good sealing and elasticity.

Experience: More than 20 years experience in rubber OEM production

Shape: According to customer's drawing

Package: PE bags, Cartons,Pallet

Payment Terms: T/T,L/C and so on.

Sample time: 25-30 days

Shipment Way: Vessel,Air,Express etc.

Below is our cooperated car brands for your reference.

Q1.Which kind of product do you produce?

Kingtom:Rubber injection parts,rubber compression parts and rubber extrusion parts,rubber-metal parts,plastic parts.

Q2.What information do you need for making price?

Kingtom:1.2D/3D drawing,or samples photo with detail size.

2.Material And Material hardness

3.Detail quantity

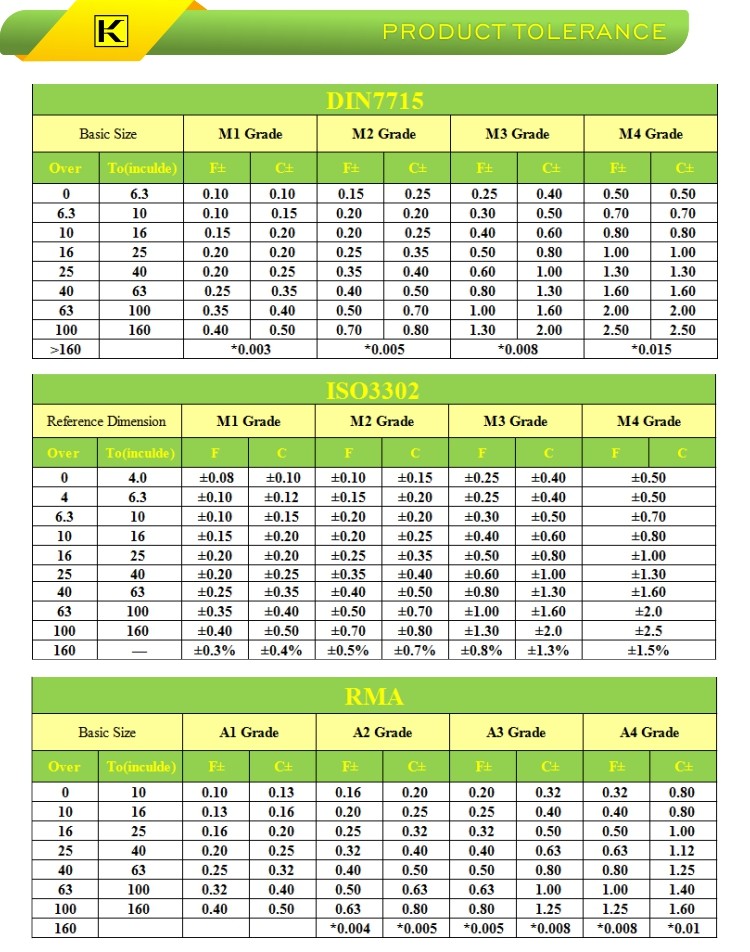

4.Your other requirements like tolerence,surface treatment.

5.Product usage environment

Q3.I don't have 3D drawing,how should i do ?

Kingtom:You can send one sample to us,then we can produce as your sample.

Q4:How to make sure the quality?

Kingtom:Check the samples before mass production.

There is the detail inspection report and goods photos before shipping.

Q5.Do you provide samples?

Kingtom:Yes,samples is free and you just pay the express cost.

Q6.How is the delivery time?

Kingtom:It usually takes 10-30days.It depends on the orders.