|

Model No

|

SS3815 King Grey

|

|

Material

|

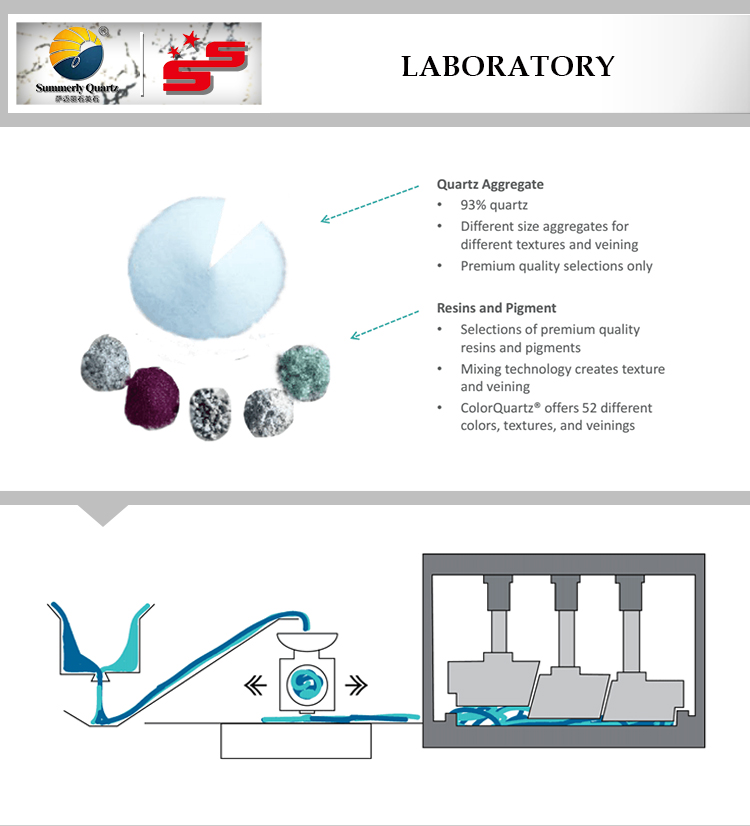

93 % pure quartz crystal, with 7 % of resins, color pigments and others.

|

|

Size

|

Slabs Size:

3000x1400mm,3000x1600mm,3200x1600mm,etc.

Tile Sze:

3300×300,300×600,600×600 and welcome customized.

Countertop Size: 48 x 26".

70 x 26", 78 x 26",

96"x26", 108"x26"

Vanity top

Size:22"x25", 22"x31",

22"x37",

22"x49",

22"x61", 22"x73"

Customized Sizes are Available.

|

|

Thickness

|

15mm, 18mm, 20mm, 30mm.

|

|

Tone & Figure

|

Consistent.

|

|

Surface Flatness

|

<0.50mm

|

|

Mohs′ Hardness

|

7

|

|

Quality control

|

Colour tone control, safe packing.

|

|

Package

|

Strong wooden bundles with fumigation.

|

|

Application

|

kitchen countertops, tabletops, vanity top, wall, floor,etc.

|

Quartz can offer simplicity in both design

and care with the added benefit of flexibility in color schemes. Quartz’s

designs also have the natural look and feel of granite, marble and other

quarried stones, and feature superior performance because of Quartz’s strength

and durability. It is non-porous. This non-porous nature provides maximum

resistance to staining, greatly reduces

the potential for bacterial growth. In

addition, it does need not for any sealing and maintenance-free.

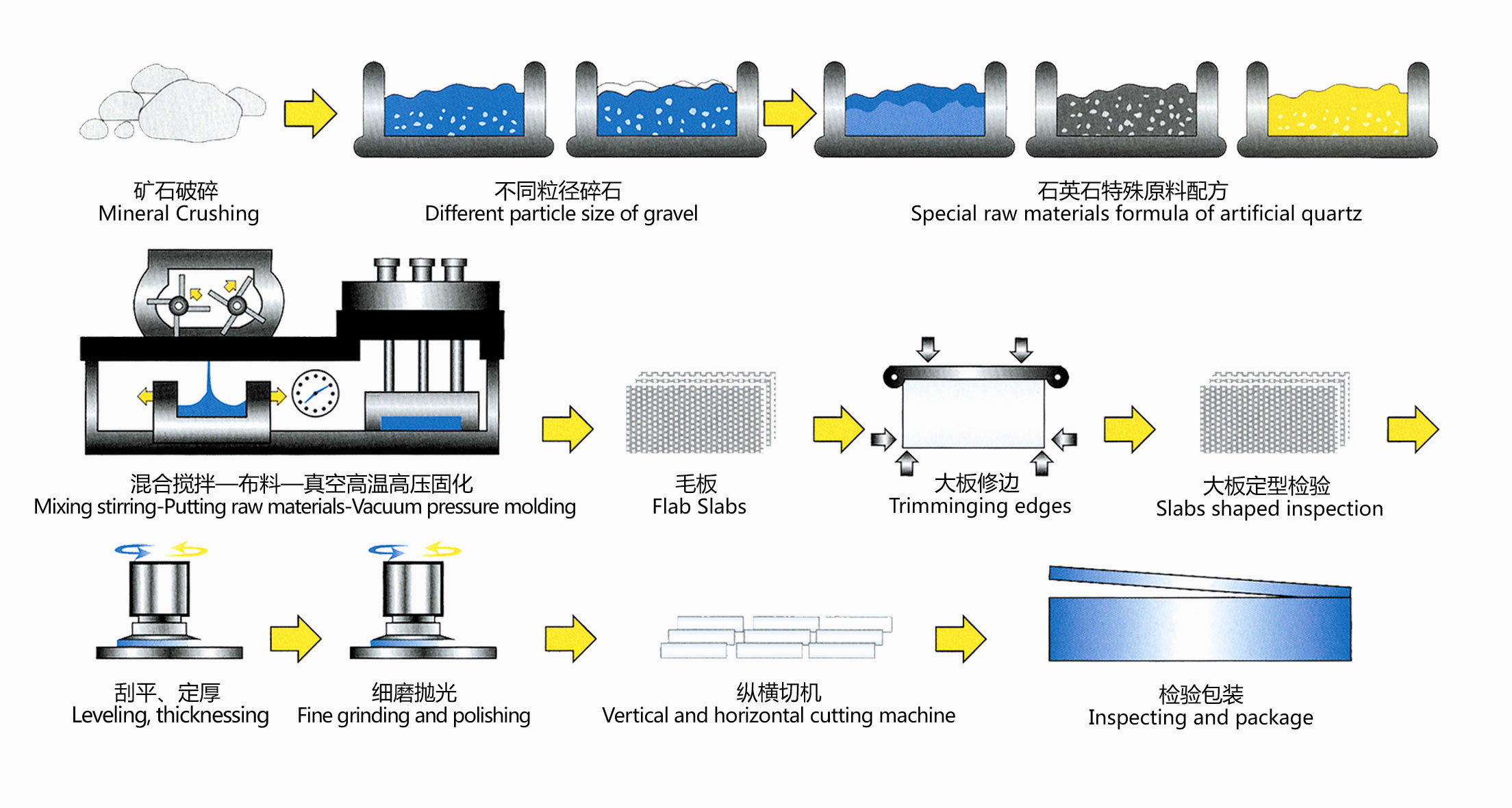

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

Laboratory: