Model No

|

SS5947-Luoduoweike

|

Materials:

|

High purity acid-washed 93% quartz stone, 7% polymer material and a small amount of inorganic pigment

|

Size:

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

Compressive Strength

|

>200Mpa

|

Harness

|

7 Mohs

|

Density

|

2.3~2.5g/cm3

|

Quality control

|

Color difference control,Safe packing,

Thickness tolerance: /-1mm

All products are checked by experienced QC piece by piece and then pack

|

Package

|

Wooden bundles for Slab, Styrofoam boxes and seaworthy wooden pallets

|

Samples

|

Free

|

Ideal Use:

|

Interior flooring, Counter tops and Vanitytops, etc.

|

Quartz is a fantastic material not only for kitchen countertops but also for kitchen, fireplaces, bars and any other area of your home. It’s an extremely versatile material due to its durability and variety of colors and designs. While other materials are limited by their design and ability to withstand certain elements, quartz has nearly limitless applications. Whether you’re remodeling your kitchen or building a new one from scratch, choosing countertops is one of the most exciting steps in the process.Quartz is one of the most popular engineered stone options on the market, so let’s focus on the many benefits it affords.

Features :

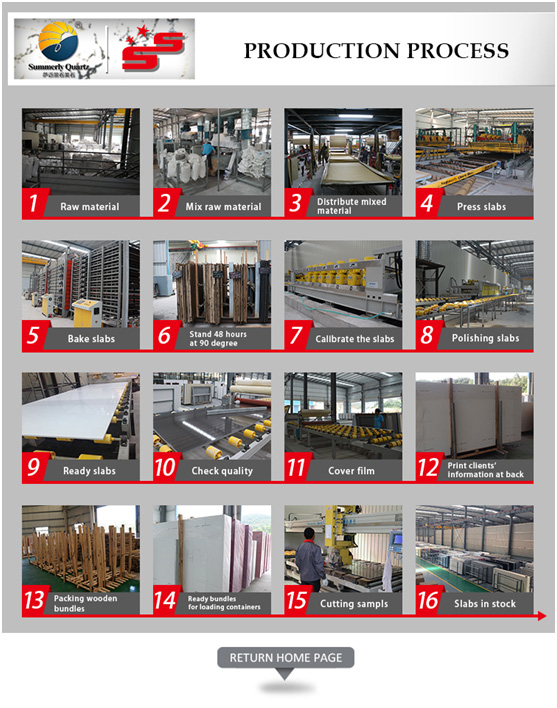

Production Engineering:

1. The process begin with a rigorous inspection of raw materials.

2. Feeding natural quartz raw material and polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed through quality inspection and packed with a plastic film.

Packing wooden crate (slab) wooden box (tiles/ countertop).