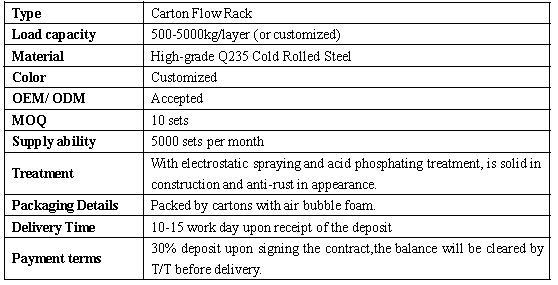

Carton Flow Rack pick system

Product description:

Features:

1. Reduced warehouse cost;

2. Easy,efficient goods loading and unloading;

3. First In First Out(FIFO) pallet goods storage;

4. Heavy duty long life construction;

5. Reduced aisie space by 60-70%;

6. Increased warehouse utilization and space savings;

7. Reduced forklift damage ad pallet or carton flows to the operator or unloading area.

Advantage:

Gravitation racking is developed from pallet rack. Fixed the track to a certain angle, the high end goods can move along the track because of gravity, which can fulfill the principle of FIFO. There is no passage between rows of racks, so space is saved.

Company Information:

Production Process

Material Preparation:Carefully selected the material, get well preparation for the next craftsmanship;

Cutting Material: Based on the size and design of products, to cut down each parts of the shelves

Bending steel: According to the workmanship of shelves, to bend the steel for purpose of matching the racks

Punching: Through punching machine, to perforate holes to each corner of steel board, this step allow each rack to combine with each other

Rolling: Processing the rolling machine then shape the steel to finish one basic racks construction

Polishing: This polishing machinery is mainly to wash out the ray abrasive damage layer and make the surface bright as one mirror.

Welding: Making welds for joints of racks and further finish the racks components

Acid Washing and Phosphating: This workmanship is aim to prevent the corrosion of steel to some extent, and function of protecting the basic body of racks. In another aspect, laying the foundation before coating could improve the adhesion and corrosion resistance of paint film and in the cold metal processing, to reduce friction lubrication.

Spray Painting and Drying: Professional spray painting machine evenly like to put on one new colorful clothes for steel board, the color could be optional then drying the steel board.

Product Packing:

Generally, shelves are flat packed by air bubble film/ film in standard export cartons. Other packing like wooden box are available to clients’ requirement.

Custom plywood crate or box for heavy sheet metal parts.

Heavy duty carton for small and lighter metal parts.

Bubble bag or protective film for inner protection to avoid scratches.

Plywood pallet is available when sheet metal products are in large amount.

Shipping marks as per request.

FAQ:

1. Q: Could you produce according to customers’ design?

A: Sure, we have very rich experience in customizing shelves.

2. Q: Can you customized style, size, colors?

A: Yes, we have rich experience more than 10 years in customization.

3. Q: Where is your factory? Can I visit ?

A: Our factory is located in Foshan, Guangdong. You are warmly welcome to visit whenever you are available.

4. Q: What is your MOQ?

A: Yes, normally will be 10- 100 sets, but with specific model, MOQ can be adjusted.

5. Q: May I know the status of my order?

A:Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.