Cast iron 2 pieces flange end ball valve

In strict accordance with the standard of GB, JB, JIS, ANSI, KS, BS, DIN, API and etc. Our ball valves have been rewarded with ISO,CE,FDA certification. We can supply selective spare parts, PTFE or RPTFE seat, SS304 or SS316 ball, square head or rectangle head stem.Our ball valve is well known for stable quality with ISO mounting pad design,which is very popular in Japan market and Germany market.

Ball valves came out in the 1950s, with the rapid development of science and technology, production technology and continuous improvement of product structure, in a short span of 40 years, quickly developed into a large class valve. In western industrialized countries, the use of ball valves is increasing every year. In China, ball valves are widely used in oil refining, gas pipeline, chemical industry, paper, pharmaceutical, water conservancy, electricity, utilities, metallurgy and other industries, occupying a key position in the national economy. Its action rotates 90 degrees, the body of the valve has the shape of a ball, with a round through hole or channel along its axis. The ball valve in the pipeline is mainly used to cut off, distribute and change the direction of flow of the medium, it only needs to rotate the work 90 degrees and very little torque to close tightly.

The ball valve is the most suitable for the switch, cut off use valve, V type ball valve. Electric valve should pay special attention to the environmental conditions of its use in addition to the parameters of the pipe. Because an electrical appliance in an electric valve is an electro mechanical device, its use by the state is highly dependent on its use of the environment. Generally, electric ball valve, butterfly valve in the next environment to use special attention.

2-PC Ball valve DIN PN16:

Application

|

|

1.Design and Manufacture

|

DIN3357

|

|

2.Face to face

|

DIN3202

|

|

3.Flange End Dimensions

|

DIN2533

|

|

4.Nominal Pressure

|

1.6MPa

|

|

5.Pressure Test

|

DIN3230

|

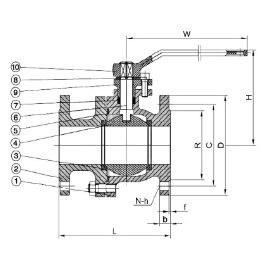

Main Parts and Materials

|

Number

|

Part Name

|

Material

|

1

|

Body

|

Grey Cast Iron(GG25 or GGG40)

|

2

|

Bonnet

|

Grey Cast Iron(GG25 or GGG40)

|

3

|

Ball

|

SS 304

|

|

4

|

Seat

|

PTFE

|

|

5

|

Gasket

|

PTFE

|

|

6

|

Stem

|

SS 304

|

|

7

|

Stem Packing

|

PTFE

|

|

8

|

Stop Collar

|

Carbon Steel

|

|

9

|

Gland Flange

|

Grey Cast Iron(GG25 or GGG40)

|

|

10

|

Lever

|

GGG40

|

Main Dimensions

|

|

Norminal

diameter

|

L

|

H

|

W

|

D2

|

D1

|

D

|

b

|

n-b

|

15

|

115

|

78

|

130

|

45

|

65

|

95

|

14

|

4-φ14

|

20

|

120

|

113

|

160

|

58

|

75

|

105

|

16

|

4-φ14

|

25

|

125

|

107

|

160

|

68

|

85

|

115

|

16

|

4-φ14

|

32

|

130

|

113

|

160

|

78

|

105

|

140

|

18

|

4-φ18

|

40

|

140

|

130

|

250

|

88

|

110

|

150

|

18

|

4-φ18

|

50

|

150

|

146

|

250

|

102

|

125

|

165

|

20

|

4-φ18

|

|

65

|

170

|

176

|

350

|

122

|

145

|

185

|

20

|

4-φ18

|

|

80

|

180

|

222

|

350

|

138

|

160

|

200

|

22

|

8-φ18

|

100

|

190

|

222

|

400

|

158

|

180

|

220

|

24

|

8-φ18

|

|

125

|

325

|

257

|

750

|

188

|

210

|

250

|

26

|

8-φ18

|

|

150

|

350

|

275

|

850

|

212

|

240

|

285

|

28

|

8-φ23

|

|

200

|

400

|

400

|

1200

|

268

|

295

|

340

|

30

|

12-φ23

|

2-PC Ball valve JIS 10K:

Application

|

1.Design and Manufacture

|

JIS B2002

|

|

2.Face to face

|

JIS B2002 Serless 6

|

|

3.Flange End Dimensions

|

JIS B2212-1999

|

Test

|

Nomlnal pressure

|

10K

|

|

Test

|

Shell(water)

|

2.4MPa

|

|

Pressure

|

Seat(Air)

|

0.8MPa

|

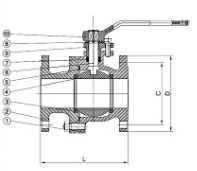

Main Parts and Materials

|

Number

|

Part Name

|

Material

|

|

1

|

Body

|

Cast Iron(FC200 or FCD400)

|

2

|

Bonnet

|

Cast Iron(FC200 or FCD400)

|

3

|

Ball

|

Stainless steel(SUS304)

|

|

4

|

Seat

|

PTFE

|

|

5

|

Gasket

|

PTFE

|

|

6

|

Stem

|

Stainless steel(SUS304)

|

|

7

|

Stem Packing

|

PTFE

|

|

8

|

Stop Collar

|

Carbon Steel

|

|

9

|

Gland Flange

|

Cast Iron(FC200 or FCD400)

|

|

10

|

Lever

|

Cast Iron(FC200 or FCD400)

|

Main Dimensions

|

|

Norminal

diameter

|

10K

|

16K

|

L

|

C

|

D

|

L

|

C

|

D

|

|

15

|

108

|

70

|

95

|

108

|

70

|

95

|

|

20

|

117

|

75

|

100

|

117

|

75

|

100

|

25

|

127

|

90

|

125

|

127

|

90

|

125

|

32

|

140

|

100

|

135

|

140

|

100

|

135

|

|

40

|

165

|

105

|

140

|

165

|

105

|

140

|

50

|

178

|

120

|

155

|

178

|

120

|

155

|

|

65

|

190

|

140

|

185

|

190

|

140

|

185

|

|

80

|

203

|

150

|

210

|

203

|

160

|

200

|

|

100

|

229

|

175

|

250

|

229

|

185

|

225

|

|

150

|

394

|

240

|

280

|

394

|

260

|

305

|

|

200

|

457

|

290

|

330

|

457

|

305

|

350

|

|

250

|

553

|

355

|

400

|

553

|

380

|

430

|

2-PC Ball valve ANSI 150LB:

Application

|

1.Design and Manufacture

|

ANSI B16.1

|

|

2.Face to face

|

ANSI B16.10

|

|

3.Flange End Dimensions

|

BS4504

|

|

4.Working Pressure

|

150PSI Steam Basic Rating

|

|

5.Pressure Test

|

API598

|

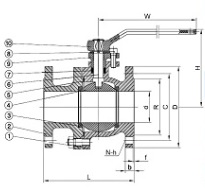

Main Parts and Materials

|

Number

|

Part Name

|

Material

|

1

|

Body

|

A126B/A536 65-45-12

|

|

2

|

Bonnet

|

A126B/A536 65-45-12

|

3

|

Ball

|

AISI 410/AISI 304

|

|

4

|

Seat

|

PTFE/RPTFE

|

|

5

|

Gasket

|

PTFE

|

|

6

|

Stem

|

SS AISI 410

|

|

7

|

Stem Packing

|

PTFE

|

|

8

|

Stop Collar

|

Carbon Steel(ASTM A307)

|

|

9

|

Gland Flange

|

A126B/A536 65-45-12

|

|

10

|

Lever

|

A536 65-45-12

|

Main Dimensions

|

|

Norminal

diameter

|

L

|

D

|

D1

|

D2

|

n-d1

|

W

|

H

|

15

|

108

|

89

|

60.5

|

35

|

4-15

|

115

|

72

|

|

20

|

117

|

98

|

70

|

43

|

4-15

|

115

|

76

|

|

25

|

127

|

108

|

79.5

|

51

|

4-15

|

150

|

92

|

|

40

|

165

|

127

|

98.5

|

73

|

4-16

|

200

|

123

|

50

|

178

|

152

|

120.5

|

92

|

4-19

|

200

|

132

|

65

|

190

|

178

|

139.5

|

105

|

4-19

|

320

|

164

|

|

80

|

203

|

190

|

152.4

|

127

|

4-19

|

320

|

173

|

|

100

|

229

|

229

|

190.5

|

157

|

8-19

|

450

|

210

|

|

150

|

394

|

279

|

241.5

|

216

|

8-22

|

850

|

288

|

|

200

|

457

|

343

|

298.5

|

270

|

8-22

|

1200

|

374

|

|

250

|

533

|

406

|

362

|

324

|

12-25

|

1420

|

366

|

|

300

|

610

|

483

|

432

|

381

|

12-25

|

1420

|

412

|

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45 days.