Ceramic Glass Sludge Waste Water Press Filter Machinery

Filter Press Characteristic:

1. The main parts of filter press is made of cast steel, Stable Structure and long usage life.

2. The filter plates are made of high intensity HDPE, the highest working pressure could be 2.5Mpa, long life span and acid and alkali resistance.

3. Adopting the contact meter to maintain the pressure automatically, saving labor labor cost and improve the working efficiency.

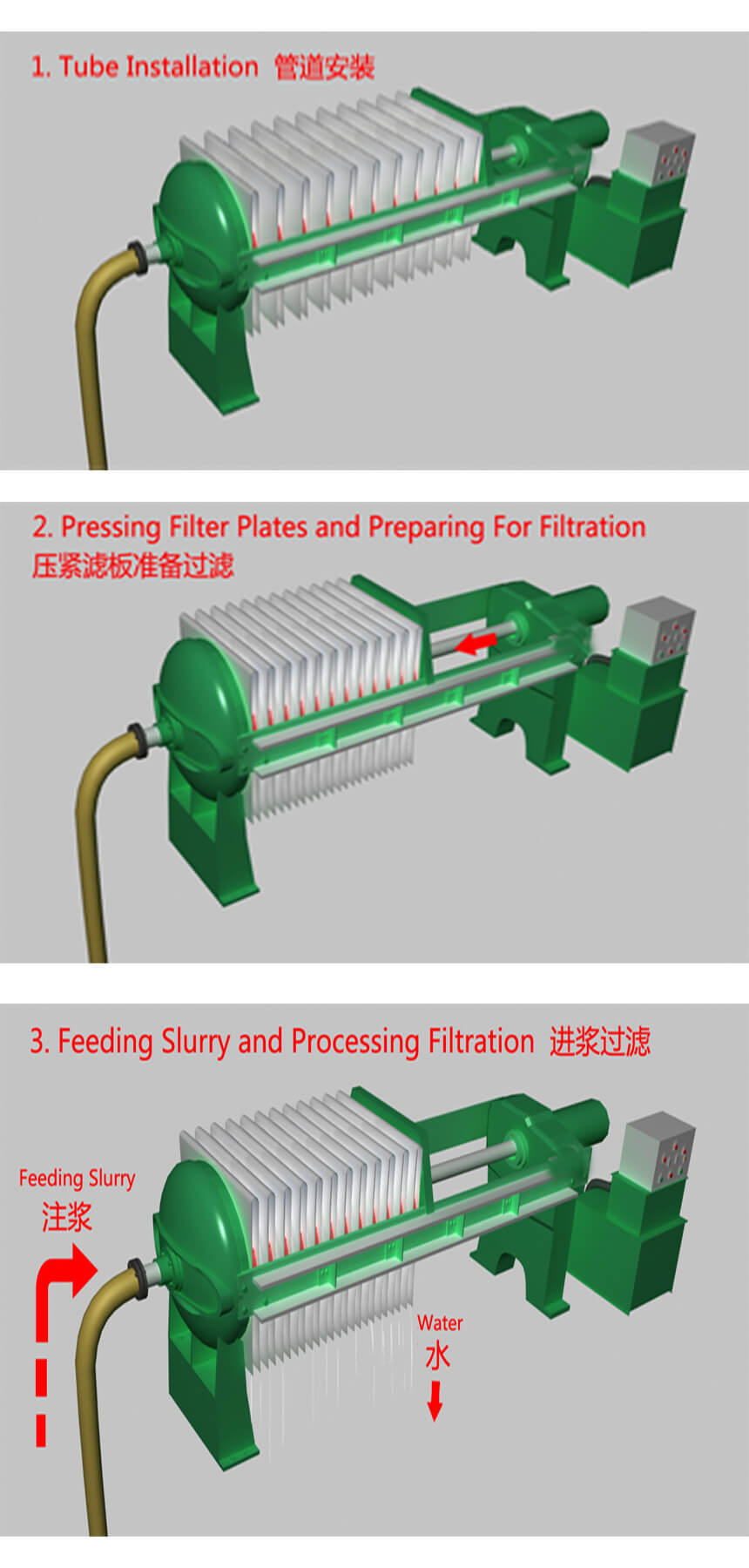

How Filter Press Work:

The filter press separates the solid in sludge from the water, recovering the water itself and reusing it in any production cycle. And the dry filtered cakes easy to be disposed of. The simplicity of the machine guarantees high-efficiency and reliability.

Filter Press Products Application:

Circular plate filter press is used in solid liquid separation industries, such as Mining, Coal, Clay, Kaolin, Wastewater Treatment (eg.: Marble, Granite, Glass, Ceramic, Electronic ceramic, etc.) , Food (Starch, Sugar) and so on.

Filter Press Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) | Weight (kg) |

L | W | H |

WYB-800 | 37 | Φ750 | 55 | 3 | 40 | 489 | ≤2.0 | 4100 | 1150 | 1170 | 2900 |

54 | 60 | 727 | 5200 | 3200 |

72 | 80 | 967 | 6300 | 3800 |

Plates could be added or reduced according to customer’s requirements.

Cast Steel Photos:

We are factory, supplying spare parts at all times, also offering professional technical support.