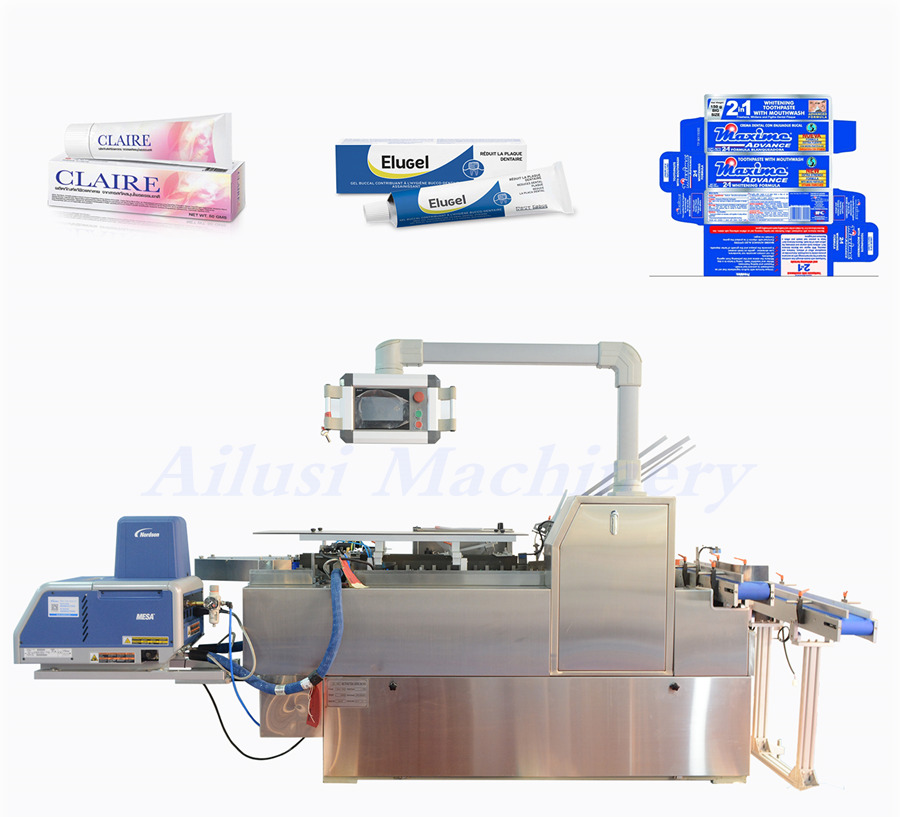

The Toothpaste Cartoning Machine will automatically package regularly shaped, single products into the packaging box using a mechanical action, then carry out automatic box loading.

Main Feature:

* The Tube Cartoning Machine can automatically complete manual folding, carton forming, opening, block boxing, batch number printing, and sealing. It can also be equipped with hot melt glue system to complete the hot melt glue sealing.

* The machine adopts PLC control. The photoelectricity monitors the actions of various parts, and if there is an abnormality during operation, it can automatically stop and display the reason for timely troubleshooting.

* The main drive motor and clutch brake are installed inside the frame, and each part of the transmission system torque overload protector is installed on the machine board. Under overload conditions, the main drive motor can be separated from each transmission part to ensure completeness. The safety of the machine.

* The Tube Box Packing Machine is equipped with an intelligent detection device. There is no manual and no paper box when there is no material, so it is convenient to work with front-end equipment. In the process of testing, waste products (without drug version, instructions) are found out at the exit, ensuring that the product quality fully meets the requirements. ..

* This machine can be used alone or in conjunction with the blister packaging machine and other equipment to form a complete production line. Automatic Tube Filling Sealing Machine, Semi Automatic Tube Filling Sealing Machine.

* The machine can change the packaging specifications according to the different use requirements of users. It is easy to adjust and debug. It is suitable for the production of large quantities of single varieties, and at the same time, it can meet the production of small batches and multiple varieties of users.

*Different type has different machine, please inquiry us the type of machine before placing an order

Working Process:

This machine adopts a series of transmissions to imitate human's actions to automatically complete the processes of box unloading, box opening and box sealing. The working process of the machine is as follows.

|

|

|

|

|

Host running speed 60-80 boxes/min

Origami Speed folding machine 60-80 sheets / minute

|

|

|

Maximum size 205(L)×80(W)×70(H) mm

Minimum size 50(L)×25(W)×14(H) mm

Can do customized, it's better to show your sample to us ;)

|

|

|

Maximum size 170(L)× 240(W) mm

Minimum size 90(L)×120(W) mm

|

|

|

|

PLC

|

Mitsubishi, Programmable controller

|

Application:

It can be used for pharmaceuticals, food products, cosmetics, and chemicals.

* Cosmetic: Face Cleaner, Hand Cream, Eye Cream, Sunscreen, Acne cream, Hair removal cream, Body lotion, Whitening Cream, etc.

* Food:Mayonnaise, Cheese, Peanut butter, Kepchup etc.

* Pharmaceuticals: Ointment, Unguent, Paste, Toothpaste etc.

* Chemicals: Painting, Shoe polish etc.

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Our Servers:

Ailusi provide Turn-key Project Service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.