Compact And High Efficiency Small Roll Ball Mill Machine

Overview

Lab roll mill is a kind of equipment used for ultra-fine grinding and mixing for laboratory and small batch production. The machine is preferred equipment for scientific research, education, experiment and production due to its advantages such as elegant and fashion design, compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials, and etc.

Working Principle

When mill works, the grinding media and the materials inside the tank are rotated to a certain height. Due to the gravity, they fall down from the tube wall. Materials are crushed by impact action of the grinding media, friction and shearing action of grinding media’s rolling and sliding.

Features

1. Compact structure, easy operation

2. High efficiency and uniform granularity

3. Milling pot in different size can be put on the driven rubber roller within a certain range by means of adjusting space between the rubber rollers.

4. It is convenient to change pots and suitable for both wet and dry grinding.

Application Cases of Planetary Ball Mill

Technical Parameters of Lab Roll Ball Mill

|

Category

|

Model No.

|

Power Supply

|

Rotate Speed

|

Max Load

Per Jar

|

Dimensions

& Net Weight

|

|

1 Work Position

|

GQM-1-5

|

220V-50Hz

or 60Hz/0.37kw

|

60-570 rpm

|

35KGS

|

730*415*260mm

32KGS

|

|

GQM-1-15

|

220V-50Hz

or 60Hz/0.75kw

|

60-570 rpm

|

80KGS

|

845*435*270mm

43KGS

|

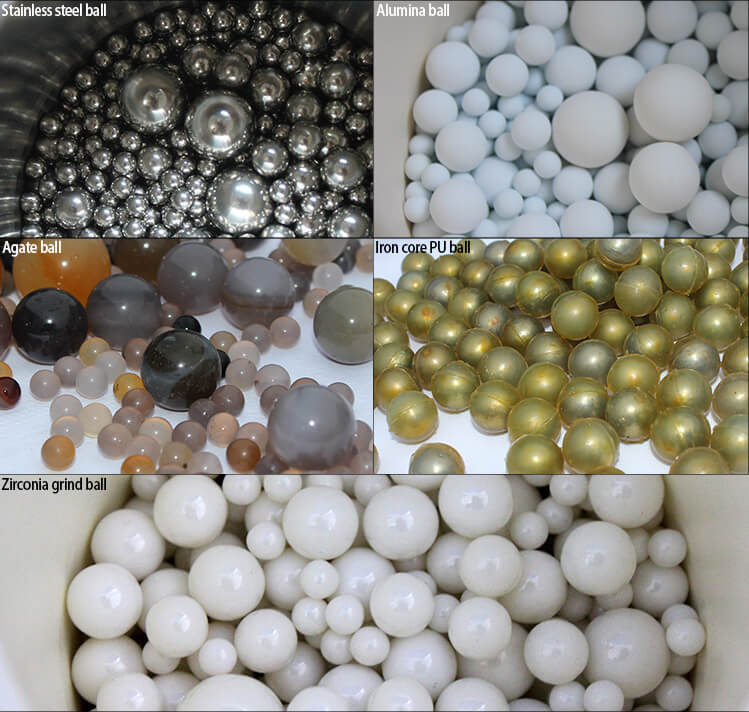

Our factory provides all kinds of mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

Available Roll Mill Jars & Specifications

|

Description of Roll Mill Jars

|

Available Specifications

|

|

Normal ceramic roll mill jar

|

From 1.0L to 15L

|

|

304 Stainless steel roll mill jar

|

From 0.5L to 20L

|

|

Alumina ceramic (Corundum) roll mill jar

|

From 0.5L to 10L

|

|

Nylon roll mill jar

|

From 0.5L to 20L

|

|

Polyurethane roll mill jar

|

From 0.5L to 20L

|

|

PTFE/Teflon roll mill jar

|

From 0.5L to 20L

|

|

Tungsten carbide roll mill jar

|

From 250ml to 3L

|

|

Roll jacket (Stainless steel)

|

0.5L to 3L

|

|

316l Stainless steel roll mill jar

|

Customized

|

Matching Solutions Recommendation for Materials & Mill Jars

|

Materials & Requests

|

Recommended Solutions

|

|

Soil materials and other materials which are not allowed with any impurity contamination

|

Agate mill jar

|

|

Metal or nonmetal which are not allowed with any impurity contamination

|

Zirconium mill jar

|

|

High hardness materials like diamond, tungsten carbide

|

Tungsten carbide mill jar

|

|

Strong add & alkali materials, or other materials under high temperature

|

PTFE mill jar

|

|

Iron ore materials or other materials with low impurity sensitivity

|

304 stainless steel mill jar

|

|

Pigment or materials with later processing under high temperature

|

Nylon mill jar

|

|

Aluminum materials like ceramic glaze

|

Corundum mill jar

|

|

Electronic materials like lithium battery

|

Polyurethane mill jar

|

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Available Mill Balls & Specifications

|

Descriptions

|

Available Specifications (Diameter Size)

|

|

304 Stainless steel mill balls

|

From 1mm to 30mm

|

|

316l Stainless steel mill balls

|

From 1mm to 30mm

|

|

Alumina mill balls

|

From 1mm-50mm

|

|

Zirconium mill balls

|

From 0.1mm to 30mm

|

|

Agate mill balls

|

From 1mm-30mm

|

|

Tungsten carbide mill balls

|

From 2mm to 20mm

|

|

Carbon steel mill balls

|

From 1mm to 30mm

|

|

Iron core PU mill balls

|

From 15mm-30mm

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.