Reliable Quality and Stability

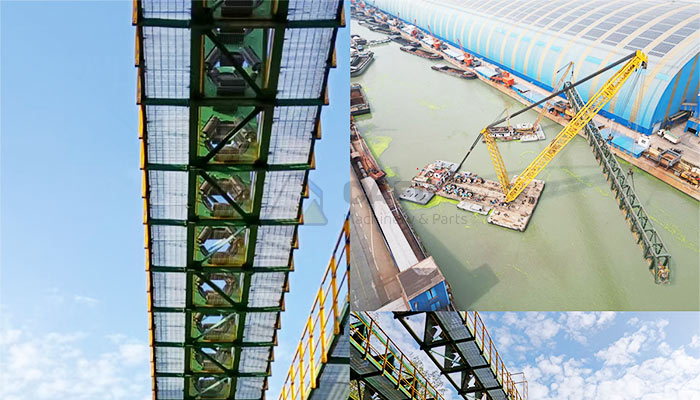

The complex terrain tubular belt conveyor is a reliable and stable solution that is widely used in a variety of applications. It is constructed with high-quality materials and advanced manufacturing techniques to ensure durability in the face of complex terrain and heavy loads. Thanks to its robust engineering, the conveyor guarantees smooth operation across a range of applications, thereby reducing downtime and maintenance costs.

In power plants, for instance, it ensures the uninterrupted conveyance of fuel and other bulk materials. In steel mills, it effortlessly handles large quantities of iron ore and coke, thereby streamlining the production process. In mining operations, it reliably transports minerals from the mine to the processing plant across challenging terrain and harsh environments.

More Efficient Customized Solutions

We provide rapid customization services to meet the distinctive requirements of each client. Our team of experienced engineers and designers work closely with customers to understand their specific requirements in terms of terrain mapping, route planning for tubular belt conveyors, and span selection for support structures. They then develop customized solutions to meet those requirements.

We can customize complex terrain pipe belt conveyors to meet the exact needs of the application, whether it's a specific conveyor length, capacity, or design feature. This flexibility enables us to provide solutions that not only meet but exceed our customers' expectations.

Wide Range of Applications

The complex terrain tubular belt conveyor is a highly versatile piece of machinery that is used extensively across a range of industrial sectors.

In power plants, the Complex Terrain Tubular Belt Conveyor is used to transport coal, wood chips, and other fuels from storage areas to boilers. This guarantees a dependable fuel supply for power generation while minimizing dust emissions and environmental impact.

In steel mills, conveyors are the optimal solution for the transportation of iron ore, coke, and scrap metal. The sealed design prevents material leakage and dust generation, thereby enhancing workplace safety and environmental conditions.

In mining operations, the conveyor can transport a variety of minerals, including coal, copper, gold, and iron ore, over long distances in complex terrain.

In addition to its applications in power plants, steel mills, and mining, the conveyor is utilized in other industries, including cement production, quarrying, and port handling. Its versatility makes it a valuable asset to companies in these industries, providing a reliable and efficient solution for bulk material transportation.

Design and Production Cycles

• Design Cycle

Once the process route has been confirmed, the design of complex terrain tubular belt conveyors can be completed within 15 to 20 days. Our team of highly skilled engineers employs advanced design software and techniques to guarantee that each conveyor meets the customer's specific requirements. The design process considers various factors, including terrain, material properties, and transportation volumes, to create a conveyor system that is both efficient and reliable.

• Production Cycle

The estimated production lead time per 1 km is 70-90 days, with delivery scheduled to commence on the 70th day. During this period, our cutting-edge manufacturing facility commences production of premium conveyor components. We utilize only the finest materials and adhere to the highest quality control standards to ensure that each conveyor meets or exceeds industry standards.

The production process commences with the procurement of raw materials, which are meticulously selected for durability and performance. Subsequently, these materials are processed and assembled into the various components of the conveyor, including the truss structure, drive system, safety guarding system, rollers, and support structure.

As production progresses, our project managers will keep the client informed of the status of the conveyor. They provide regular updates on the production progress and respond to any customer inquiries. This communication and transparency foster a trusting between our company and our customers.

Installation and Service

• Installation Cycle

As an example, the installation cycle time for a conveyor measuring 1 km in length is approximately 60-80 days. (Please note that the actual installation period may vary depending on the installation conditions available for the project.)

Our experienced team of installation guides is trained to develop the optimal installation plan and organize the project installation team to complete the conveyor installation in the shortest possible time.

• Installation Service

Our professional engineers provide on-site installation guidance and services worldwide until successful commissioning, as well as training on the operation and maintenance of tubular belt conveyors. Our team of engineers has extensive experience installing tubular belt conveyors in complex terrain worldwide. They possess a deep familiarity with a range of terrains and installation challenges, enabling them to devise bespoke solutions that guarantee successful installations.

Our installation guidance services for complex terrain tubular belt conveyors are designed to provide a seamless, hassle-free experience for our customers. From installation to commissioning and training, our professional engineers are dedicated to ensuring the success of each project and providing the highest level of service and support to our customers.