|

Model

No

|

SS V002

Oyster

|

|

Materials

|

High

purity 93% natural quartz powder, 7% unsaturated polyester resin and small

amount of pigment .

|

|

Size

|

3000x1400mm,3000x1600mm,

3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12

mm, 15 mm, 18 mm, 20 mm, 30 mm ,etc.

|

|

Surface

Finish

|

Polished,

Honed,etc.

|

|

Mohs′ Hardness

|

7

|

|

Water

absorption

|

<0.05%

|

|

Packing

|

Wooden

bundles, Iron Bundles, wooden crates and wooden cases

|

|

Service

|

We

can offer high quality, competitive price and swift delivery.

|

|

Applications

|

countertop,

Vanity top,worktops, window sill, Wall Tiles, etc.

|

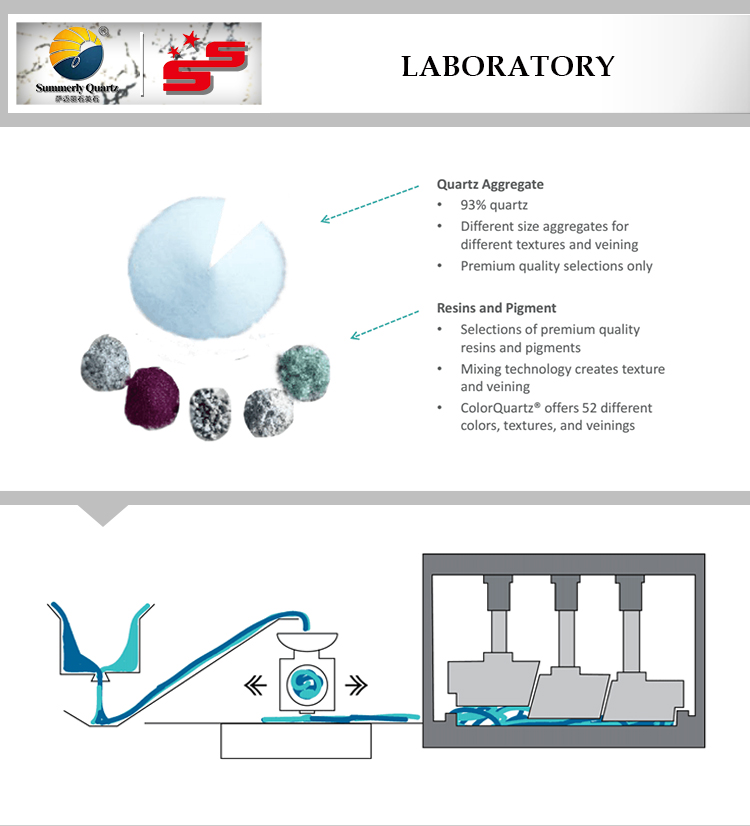

Quartz countertops calls for a blend of

materials with at least 90 % natural quartz and resin. Over the years, higher

quality manufacturing standards called for natural-stone fragments to be as

high as 93%. Quartz is produced in a broad range of colours. If you want to

have a choice between a natural looking slab and solid colour, quartz can

provide you with it.

Engineered stone isn’t porous, which means

hard water deposits won’t penetrate below the surface, thus eliminating the

potential issue of etching. Quartz is also stain resistant and that gives you

peace of mind when choosing a light colour too, because you aren’t going to

have any nasty stains, such as red wine or lemon, coffee,juice, provided you

clean them up straightaway.

Quartz is a great choice for your bathroom

or kitchen.There are not only numerous styles available, but it’snever needs

sealing. It’s also resistant to mold and easy to look after. You just need to

wipe it down whenever it’s wet or it looks smudged.

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

Laboratory:

Packing: