|

Item No

|

SS3991 Blanco White

|

|

Type Name

|

Quartz Stone,Quartz Slabs,Artificial quartz stone

|

|

Composition

|

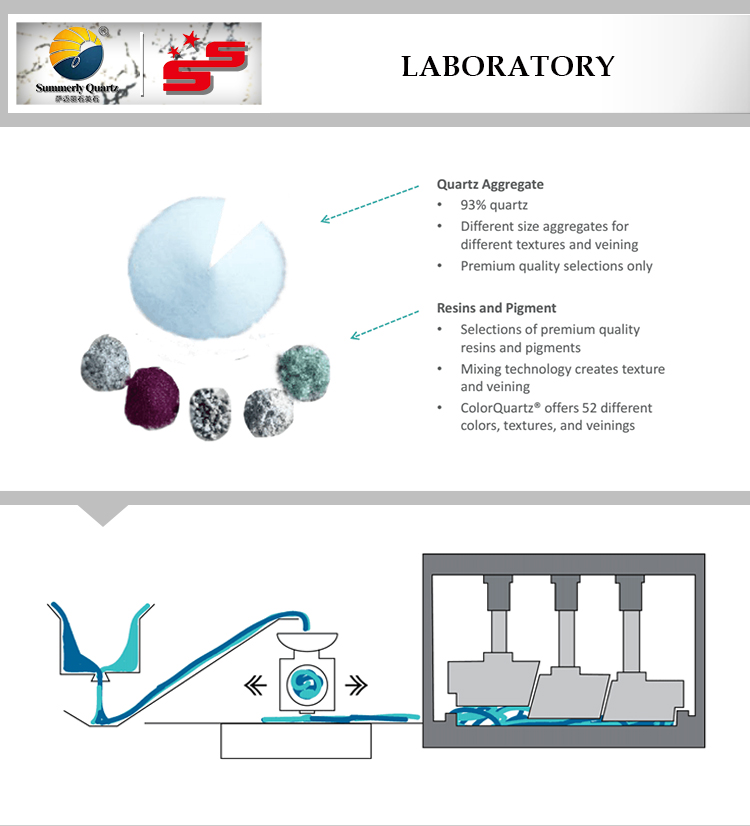

High purity acid-washed 93% quartz stone, 7% polymer material and a

small amount of inorganic pigment.

|

|

Size

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12mm, 15mm, 18mm, 20mm, 30mm,etc.

|

|

Thickness tolerance

|

±1mm

|

|

Surface Finish:

|

Polished, Honed,etc.

|

|

Package

|

Outside with seaworthy strong wooden crate; Inside with soft plastic

foam.

|

|

Usage

|

kitchen countertop, bar tops, Dinner tops, etc .

|

|

MOQ

|

100square Meter

|

|

Payment terms

|

T/T, L/C at sight

|

When installing new countertops, engineered

stone can often provide more dramatic looks than natural stone. Various

materials can be added to the quartz and resin mixture during manufacturing

such as different types of stone or crushed glass, creating unique design

effects.Whether you choose honed or polished quartz, your countertop surface

will ultimately add to, or take away from, the overall aesthetic and vibe of

each room.

Quartz countertop is no need for a sealant or protective wax

coating. Consequently, they require less maintenance when compared to natural

stone countertops. On the other hand, quartz is highly resistant to staining.

It has a sleek and non-porous surface that doesn’t absorb liquids. Granite is

not as prone to staining as some other stones, but it also not as highly

resistant as quartz.

Engineered Quartz allows for a variety of

edging options, and unlike granite, it can be used on sizable vertical surfaces

without the visible seams that are evident with natural stone.Extremely durable

and strong, this material will make even a small bathroom look awesome. Also

called engineered stone, quartz is built to last. Choosing such an option means

you will have tops to boast about for decades to come.

About the Quality

1.

Thickness: Quality allowed +-0.5mm. In production, we will measure the

thickness three times to make sure it is qualified.

2. Size: We will make the slab 20mm longer and wider to make up the lack of

corner problem that possiblely happen.

3. Production line QC will inspect the slab surface meter by meter to make sure

the there are no bubble and other quality problem.

4. General QC will inspect the quality again, to make sure the whole quality is

good.

5. We supply two years's quality warranty, if you found any quality problem

within two years after you received the slabs, you can contact with our

saler.

Laboratory:

Sample Room: