Small Area UV LED Light Source Curing Lamps, its luminescent mode emits a linear light spot, is made of numbers of LED chips. According to choose different wavelength (365nm, 385nm, 395nm, 405nm) and different light spot (10*200,etc., can be customized), the product can be satisfied with UV glue, UV ink, UV gloss oil, UV printing, UV adhesive, etc. on different materials’ requirements.

Parameters of Linear Irradiation UV Curing Light Source for UV Ink :

1.Appearance interface, liquid crystal display, operation intuitive.

A host can control two channels, each of which can be controlled individually or linkage.

2.Time、power、mode are flexible setting

Each channel can be set time between 000.0s~999.9s according to the curing time.

Each channel can be adjusted power between 0%~100%.

Each channel can be set with four modes :

A : Automatic mode, energy and countdown timer setting.

M : Manual mode, energy setting.

ST : STEP mode, step number setting, the front number represents the number of steps.

CLOSE : the channel closed.

3.Key control, foot control, I/O signal interface control, RS-232 compute or PLC control.

4.Long service life, high cost performance

Compared with traditional curing equipment, the service life of its mercury lamp is only 800-2000 hours, the service life of using LED light is over 20000 hours which indirect use is long.

The service life of LED is 30-40 times than mercury lamp. The LED light reduces changing the number of light bulbs, improves production efficiency, and also is very energy-saving. However, traditional mercury lamp, when the curing facility is working, because mercury lamp starts slowly and affects bulbs life by opening and closing, should be lighted up all the time, which will cause necessary power consumption and reduce the working life of mercury.

5.High power, low energy consumption, no thermal radiation, ROSH

With high power LED chip and special optical design, ultraviolet light reaches high precision and high intensity irradiation. UV output reaches 2500mW/cm2 Irradiation intensity. Using the latest optical technology and manufacturing process, to achieve high strength and uniformity which is the better than irradiation mode of traditional mercury lamp. The light is without preheating the tubes, when using instantaneous high power up to 100%, out-of-box, high conversion efficiency of ultraviolet photoelectricity, no toxic mercury, doesn’t produce ozone, is a safer and more environmentally friendly alternative to traditional light source.

Applications of Most Powerful UV LED Light Array for 3D Printing :

UV glue curing, printed circuit exposure, ink curing, mobile phone original assembly, optical communication industry components, microelectronics, liquid crystal, PCB, optical communication and other fields.

|

Type

|

UV-80

|

UV-86

|

|

Channel

|

CH1、CH2

|

CH1

|

|

Time Set

|

000.0s~999.9s

|

NO

|

|

Power

|

0%~100%

|

Manual

|

|

Mode

|

Manual, Automatic, Step, Pulse

|

Manual

|

|

Control

|

Touch, Foot-Switch, Serial Interface

|

Foot-Switch

|

|

Voltage

|

100-240VAC.50/60HZ

|

100-240VAC.50/60HZ

|

|

Humid Environment

|

+5-+40℃ 20-85%

|

+5-+40℃ 20-85%

|

|

Storage Humid Environment

|

-10-+60℃ 20-85%

|

-10-+60℃ 20-85%

|

|

Weight

|

6KG

|

5KG

|

Note: sizes can be customerized.

|

Type

|

Light Source

|

Wavelength

|

Size of Irradiation Head

|

Cooling Method

|

Irradiation Power

|

|

UV3-25

|

LED Chip

|

365nm 385nm 395nm 405nm

|

3*25

|

Air Cooling

|

500-1000mW/cm2

|

|

UV5-50

|

LED Chip

|

365nm 385nm 395nm 405nm

|

5*50

|

Air Cooling

|

100-2500mW/cm2

|

|

UV5-100

|

LED Chip

|

365nm 385nm 395nm 405nm

|

5*100

|

Air Cooling / Water Cooling

|

100-2500mW/cm2

|

|

UV5-200

|

LED Chip

|

365nm 385nm 395nm 405nm

|

5*200

|

Air Cooling / Water Cooling

|

100-2500mW/cm2

|

|

UV10-120

|

LED Chip

|

365nm 385nm 395nm 405nm

|

10*120

|

Air Cooling / Water Cooling

|

500-1800mW/cm2

|

|

UV10-200

|

LED Chip

|

365nm 385nm 395nm 405nm

|

10*200

|

Air Cooling / Water Cooling

|

500-1800mW/cm2

|

|

UV10-300

|

LED Chip

|

365nm 385nm 395nm 405nm

|

10*300

|

Air Cooling / Water Cooling

|

500-1800mW/cm2

|

|

UV10-350

|

LED Chip

|

365nm 385nm 395nm 405nm

|

10*350

|

Air Cooling / Water Cooling

|

500-1800mW/cm2

|

|

UV10-400

|

LED Chip

|

365nm 385nm 395nm 405nm

|

10*400

|

Air Cooling / Water Cooling

|

500-1800mW/cm2

|

|

UV15-480

|

LED Chip

|

365nm 385nm 395nm 405nm

|

15*480

|

Air Cooling / Water Cooling

|

500-1500mW/cm2

|

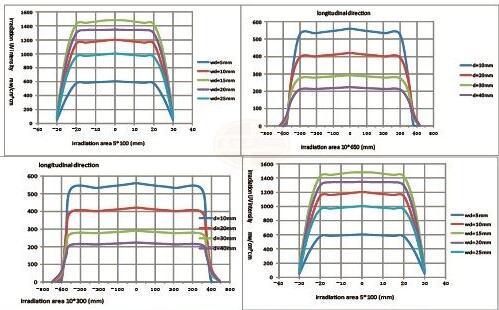

Optical Power Graph of Customized UV LED Curing Systems for Offset Printing :