Product Description:

|

Item No

|

SS-V008 Emperador

|

|

Composition

|

93 % pure quartz crystal, with 7 % of resins, color pigments and others .

|

|

Size

|

3000x1400mm,3000x1600mm,

3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12mm, 15mm, 18mm, 20mm, 30mm

|

|

Finished

|

Polished,

Honed, etc

|

|

Mohs' hardness

|

Grade

6-7

|

|

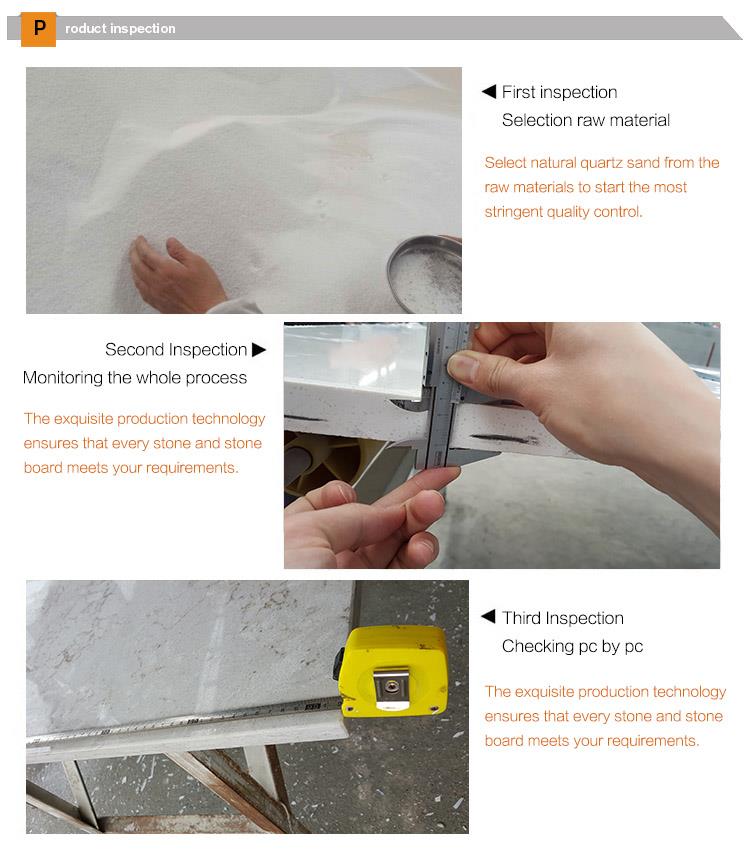

Quality Control

|

Confirmed

Every Details Before Make the Rough Production

|

|

Thickness

tolerance:+/-0.5mm,+/-1mm+85°up Polished

|

|

All

Products were Checked by Experienced QC Before Pack

|

|

Packing

|

By Seaworthy Standard Packing

|

|

Inner With Foamed Plastic

&Outside With Fumigated Wooden Crates

|

|

Payment Terms

|

30%

T/T deposit in advance before production arranged. 70% T/T balance payment

before delivery from factory

|

Quartz is the most durable and luxurious

material available for countertops and is perfect for homes,condo,

hotel,offices, retail stores, Airport building and more. It is made of at least

93% naturally mined quartz and combined with high-quality polyester resins and

pigment to give you an option without the maintenance of similar products. We

believe they are more perfect for homes for several reasons:

1.Heat and Scratch Resistant

2. Non-porous and does not need to be

sealed.

3.it is very low-maintenance and cleaning

is Easy

4.Resistant to bacteria and anti-corrosion

5.Widest colour palette

Quartz is so versatile that you never have

to worry about not being able to do what you want with your home. Whether you

want to use it for your bathroom vanity top, kitchen work top or even wall

cladding, you can do just that.

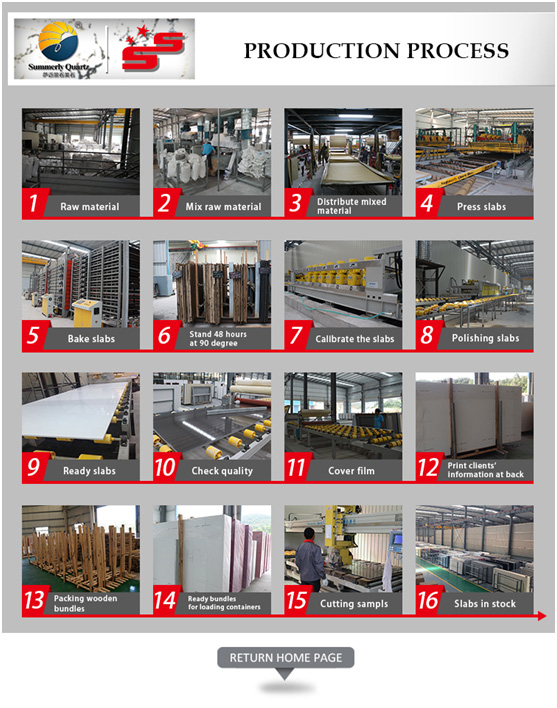

The Production Process:

1.

The process begins with a strict inspection of raw materials.

2.

The natural quartz raw material and polymer resins and inorganic pigments are

put into the mixers and mix together.

3.

After mixing, pour them into a mold and form them into slab size.

4.

Pressing: Then the slab is compacted by a special vacuum and vibration process

at pressure machine.

5.

Then the slab is moved to the curing kiln and heated for a period time to make

their final strenth and srurdiness.

6.

Cut edges, flat , thicknessing and polishing surface to perfect finished.

7.

Finally, through quality inspection and plastic film packaging

Product Inspection: