CNG TYPE 1 GAS CYLINDER

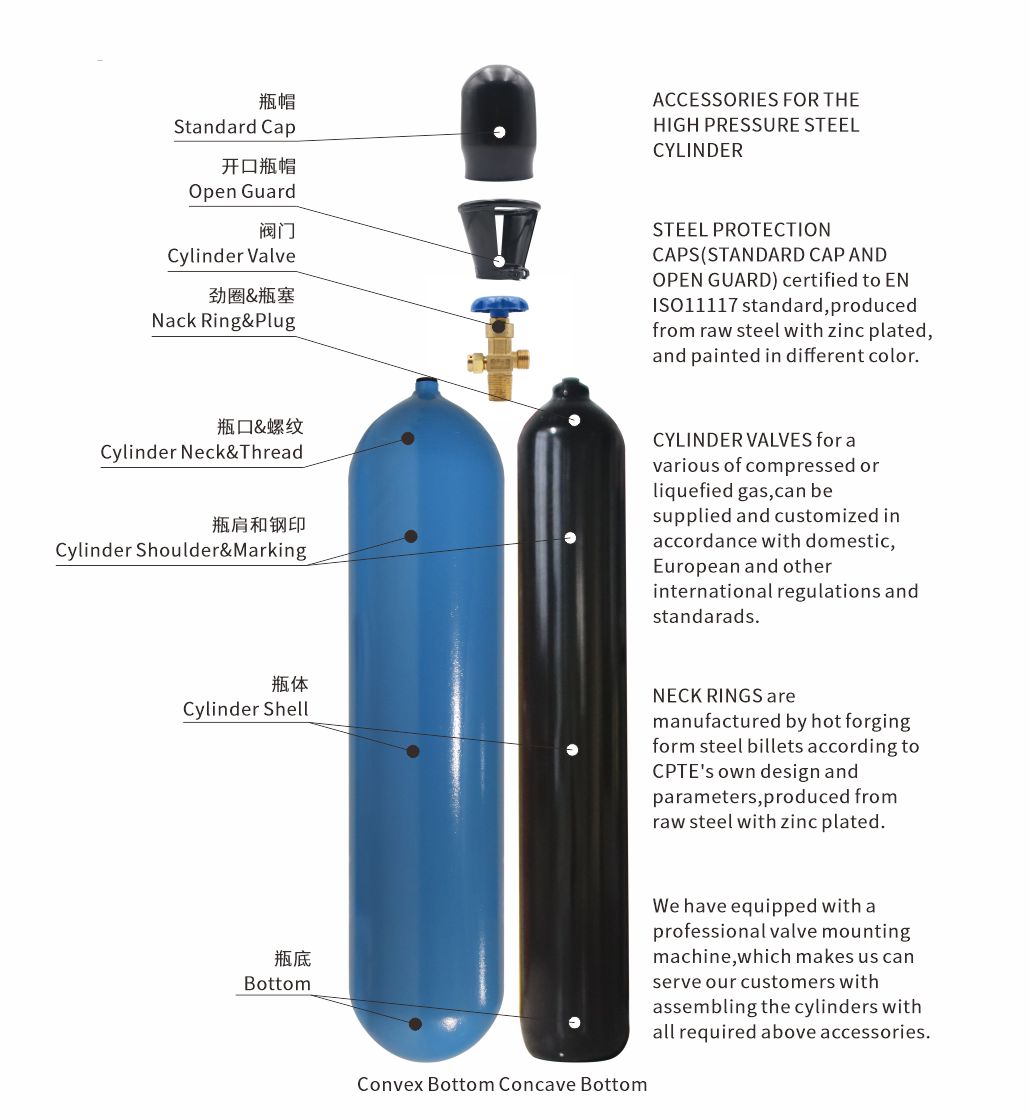

Compressed natural gas (CNG) cylinders are used to store and transport natural gas for use by vehicles such as cars. CNG cylinders are typically made of high-strength steel or other materials and are specifically designed to withstand compressed natural gas at high pressures. Automobile cylinder appearance color can be customized according to market demand; Automobile cylinder size can be customized according to market models to 80L-220L, logo valves can also be customized according to market demand. These cylinders are ECE R110 compliant, have a working pressure of 200bar and a test pressure of 300bar, and are made of materials such as 34CrMo4.

| Implementation standard |

Norminal Working

Pressure(Bar)

|

Hyd.test Pressure

(Bar)

|

Design Wall Thickness

(mm)

|

Material |

Bottom Shape |

Outer Diameter

(mm)

|

Water Capacity

(l)

|

Length(mm) |

Weight(kg) |

|

ECE R110

|

200 |

300 |

8.5 |

34CrMo4 |

Convex |

406 |

80 |

860 |

84.4 |

| 90 |

945 |

92.2 |

| 100 |

1045 |

103.2 |

| 220 |

2065 |

197.5 |

Range of Application:

CNG cylinders can be used to store and transport natural gas as fuel for a variety of vehicles, including cars, buses and trucks, as well as to operate gas stations. Lower fuel costs, lower gas emissions and improve vehicle performance.

Why Choose Us?

- Strong production capacity:With a self-built factory covering over 56,000 square meters and employing over 240 staff, the company has the capacity to produce 300,000

- Direct sales from the source factory:By eliminating foreign trade companies, purchasers can directly access the manufacturer for one-stop procurement

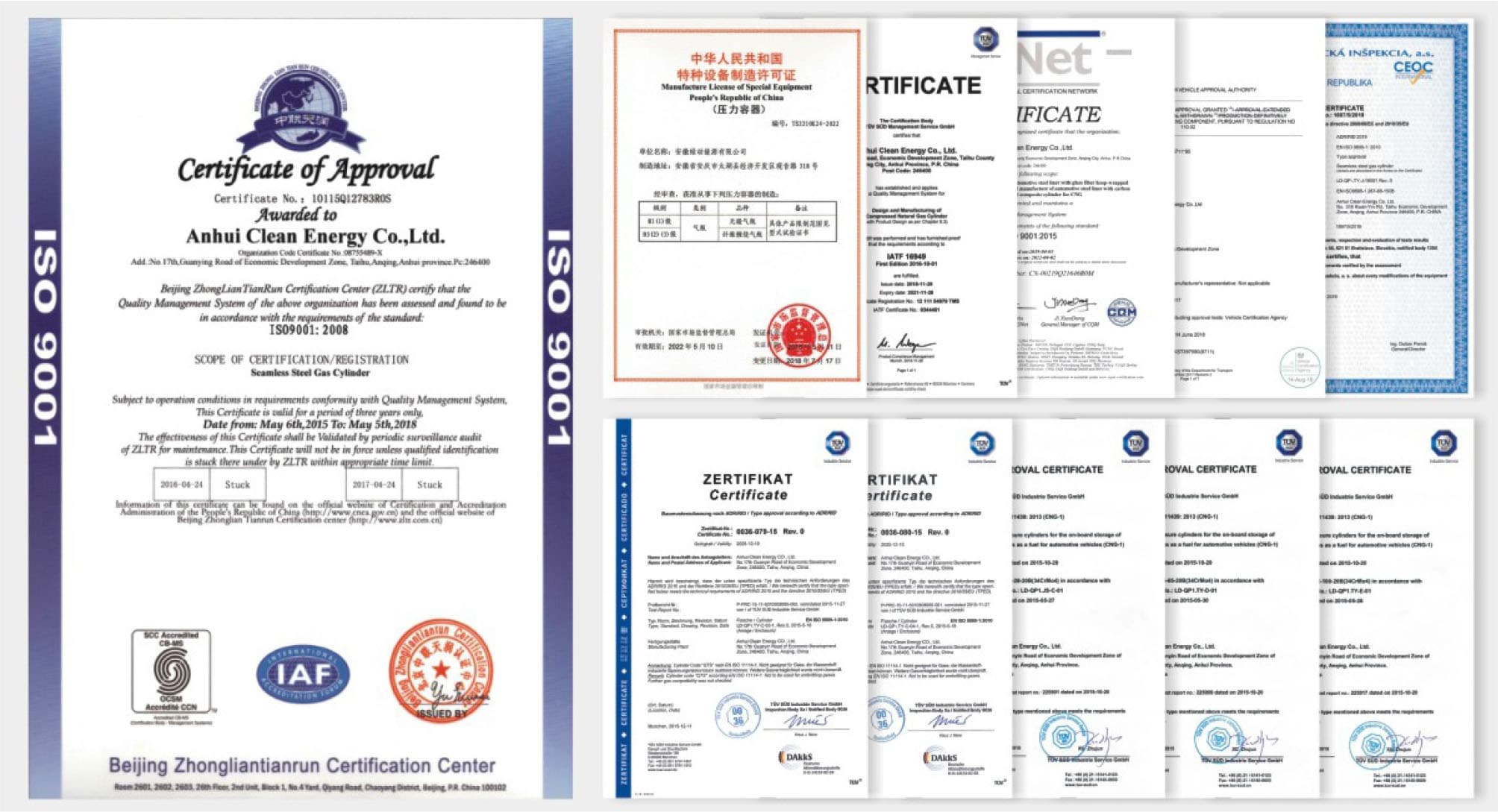

- 10 years of industry experience:The factory holds IATF 16949 and ISO 9001 quality management system certificates,

- Customization capability:Our products can be customized according to your preferences, including color, size, thread, and logo.

- At present, the company has 6 gas cylinder spinning production lines, 3 heat treatment and tempering lines, 2 automatic production lines for machine adding, spraying and winding, and 1 LPG composite gas cylinder production line

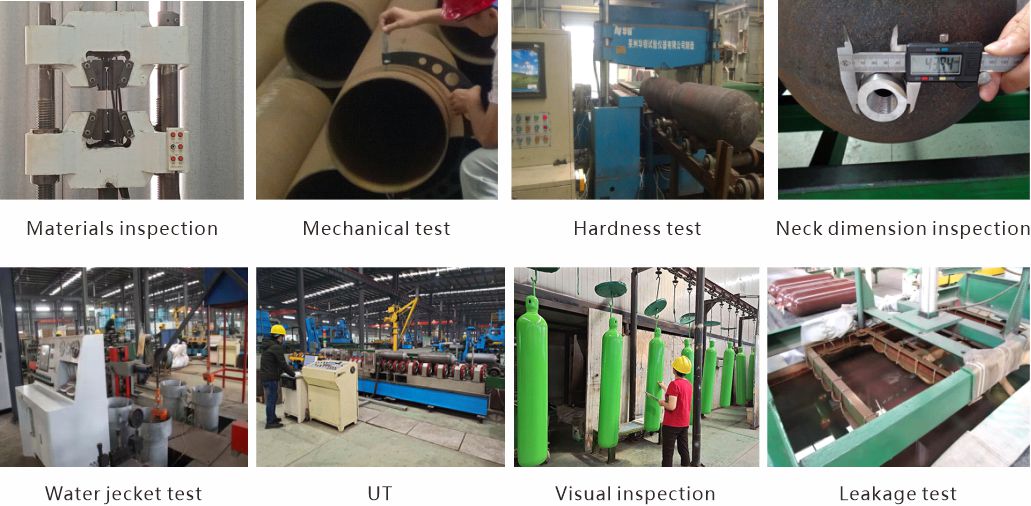

CNG Cylinder Product Inspection Display

The factory undergoes multiple cylinder inspections to ensure product safety and reliability, so you can purchase with confidence and use with safety. Each inspection procedure is scientific and rigorous, leaving no room for any negligence. From material selection to production processes, CNG cylinders strive to combine excellent quality with impeccable safety. Every aspect highlights exquisite craftsmanship and quality assurance.

Quality Control

We have ISO 11439, ISO11119, ISO9089, UN ISO9809, ECE R110, EN11245 and other international certificates, as well as the company's own ISO9001 and IATF 16949 and other international quality system certificates. Having these certifications is an affirmation of our quality control system and the best confirmation of our excellence. We always adhere to the best quality materials, the most advanced production technology, the most rigorous quality control, for every customer to create excellent products.

Since its establishment over ten years ago, the company has a self-built factory covering an area of 56,000 square meters. We currently have a workforce of 240 employees, including 50 senior technical and management personnel. Additionally, we possess the production capacity to manufacture 300,000 various types of gas cylinders per year, as well as 9,000 sets of CNG framework assemblies and gas supply systems.