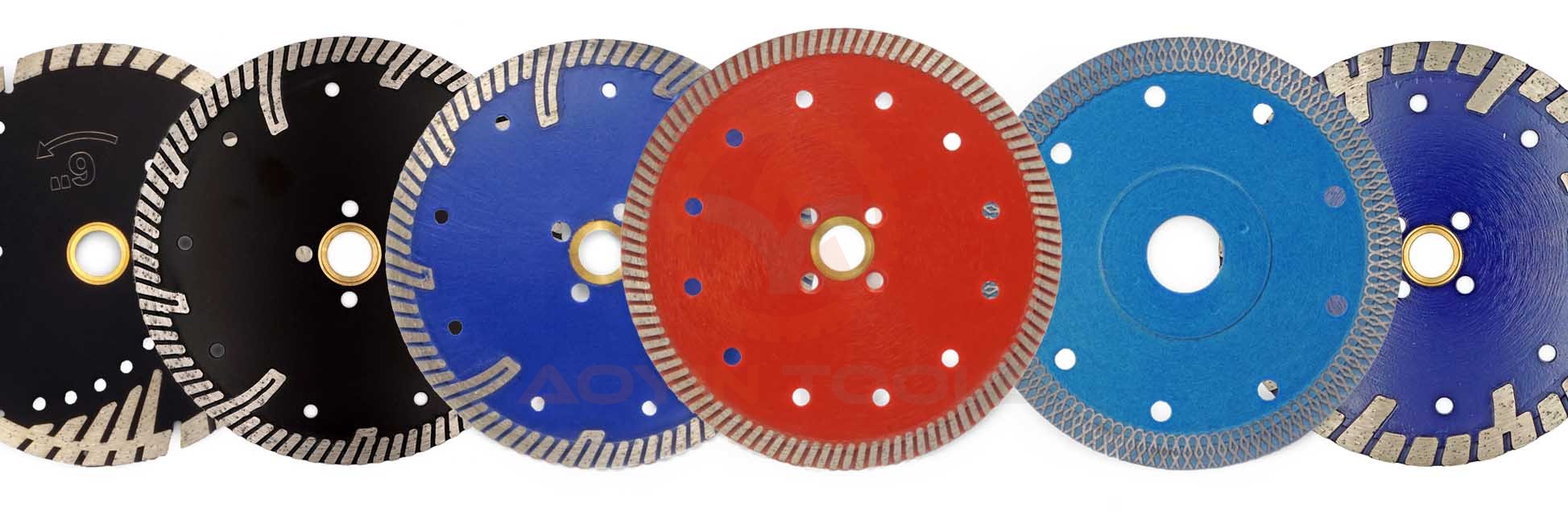

Diamond Narrow Continuous Turbo Rim Blade For Granite Marble

Product Description:

The continuous diamond thin turbo blade is specifically designed for cutting granite and marble materials with precision and efficiency. The turbo segmented rim ensures smooth and fast cutting, while the thin blade design reduces material wastage during the cutting process. It is a versatile tool suitable for both wet and dry cutting applications.

Key Features:

1. High-Quality Diamond Segments: The blade features high-quality diamond segments with sharp and durable cutting edges, providing superior cutting performance and long blade life.

2. Turbo Segmented Rim: The turbo segment design enhances cutting speed and ensures clean and chip-free cutting results, even when dealing with hard materials like granite and marble.

3. Thin Blade Design: The thin blade design minimizes material wastage and ensures accurate and precise cuts, enabling efficient cutting of costly stone materials.

4. Versatile Application: The blade can be used for wet or dry cutting applications, giving users the flexibility to choose the most suitable cutting method based on their requirements and preferences.

5. Compatibility: The Continuous Diamond Thin Turbo Blade is compatible with angle grinders and circular saws, making it a versatile tool for both professional contractors and DIY enthusiasts.

Product Specifications:

- Blade Diameter: (specify the diameter)

- Arbor Size: (specify the arbor size)

- Segment Height: (specify the segment height)

- Cutting Material: Granite, Marble

- Application: Wet/Dry Cutting

- Maximum RPM: (specify the maximum RPM)

| Product Name |

Diamete (mm) |

Core Diameter (mm) |

Segment Dimension (mm) |

Segment Number |

| Narrow Continuous Turbo Rim Blade |

D105 |

20

22.23

25.4

|

T2.4*H10 |

56 |

| D110 |

T2.0*H10 |

64 |

| D115 |

T2.4*H10 |

60 |

| D125 |

T2.6*H10 |

64 |

| D125 |

T2.6*H8 |

84 |

| D130 |

T2.6*H10 |

64 |

| D150 |

T2.6*H10 |

75 |

| D180 |

T2.8*H8 |

106 |

| D180 |

T2.8*H10 |

96 |

| D200 |

T2.8*H10 |

108 |

| D230 |

T3.0*H10 |

120 |

FAQ:

Q1: How to choose the right diamond tool for my project?

A1: The choice of diamond tool depends on factors such as the material to be worked on, the desired finish, and the equipment being used. For example, for stone cutting, a continuous rim diamond blade is suitable, while a segmented diamond blade is more suitable for concrete.

Q2: Can diamond tools be used on different types of stone?

A2: Yes, diamond tools are versatile and can be used on various types of stones like granite, marble, limestone, and more. However, it is essential to ensure that the tool is specifically designed for the type of stone you intend to work on to achieve optimal results and avoid any damage.

Q3: Are there any safety precautions to consider when using diamond tools?

A3: Yes, when using diamond tools, it is crucial to follow safety guidelines. Wear protective gear such as safety glasses, ear protection, and gloves. Ensure that the work area is well-ventilated. Always read and follow the instructions provided by the tool manufacturer. Additionally, regularly inspect the tool for any damage and replace it if necessary.

Q4: Do you offer customization or wholesale options for your products?

A4: Yes, we offer customization services for specific tool requirements or bulk orders for our products. Please contact our customer service team with your specific needs, and we will be happy to assist you with customizing the tools or providing wholesale pricing information.

Please Note:

- Always follow proper safety precautions and wear appropriate protective gear, including goggles, gloves, and a dust mask, when using the blade.

- Cool the blade with water during wet cutting to prolong its lifespan and enhance cutting performance.

- Avoid applying excessive pressure while cutting to prevent blade damage and ensure optimal cutting results.

For more detailed information and pricing, please contact our sales team.