Double Portrait Horizontal Single-axis Solar Tracker System

Product Description

Wintop double portrait horizontal single-axis solar tracker system, a double-row solar panel can generate more electricity at the same time than a single-row solar panel.

The single-axis solar tracker rotates on one axis and moves back and forth in one direction. Different types of single-axis trackers include horizontal, vertical, tilt, and polar alignment, which rotates as the name implies.

Technical Parameters

|

PV-Modules

|

|

PV- Modules supported

|

Fully fit for 210 module

|

|

Structure

|

|

System type

|

One portrait horizontal single-axis tracker

|

|

Maximum capacity per row

|

54kWp (Estimated with 600W PV-Modules)

|

|

PV- Module quantity per row

|

2PX45,2PX30

|

|

Tracking Range

|

±60°(Customized according to project)

|

|

Tracking accuracy

|

±1°

|

|

Motor quantity

|

1 motor per row

|

|

Structural Materials

|

HDG Steel, Al- Mg-Zn Coating Steel

|

|

Foundation

|

Concrete foundation, Steel pile, PHC pile

|

|

Quantity of foundation/MW

|

130 PCS/ MW (Estimated with 600W PV-Modules)

|

|

Electrical

|

|

Solar tracking method

|

Astronomical algorithm + closed- loop control (AI)

|

|

Control system

|

MCU

|

|

Signal transmission

|

Wire (RS485) or wireless (Zigbee)

|

|

Drive method

|

Slew Drive

|

|

Motor Type

|

24V DC Motor

|

|

Power supply

|

AC- powered or self- powered

|

|

Backtracking

|

Yes

|

|

Manual operation

|

Yes

|

|

Protection function

|

|

Wind protection

|

≥18m/s

|

|

Night stow mode

|

Yes

|

|

Overheat prevention

|

Yes

|

|

Overheat prevention

|

Yes

|

|

System fault self-diagnosis

|

Yes

|

|

Rotate to horizontal time

|

4-5min

|

|

Environment

|

|

Wind load

|

Customized according to local condition

|

|

Operating temperature

|

-30℃ ~ +60℃

|

|

Operating temperature

|

C5

|

|

Slope tolerance

|

North-south 10%~20%, East-west no limits

|

|

Other

|

|

Special tools

|

Not required

|

|

Load design standard

|

GB, ASCE, BS EN,AS (according to project)

|

Electrical Principle

Features & Benefits

-

Fully fit for 210 module

-

Intelligent AI algorithm to improve power generation

-

Adaption to various terrains allowing a north-south slope up to 10% to 20%

-

Easy installation and easy maintenance

-

Stable and reliable operation

-

Power generation increasement of 15-30%

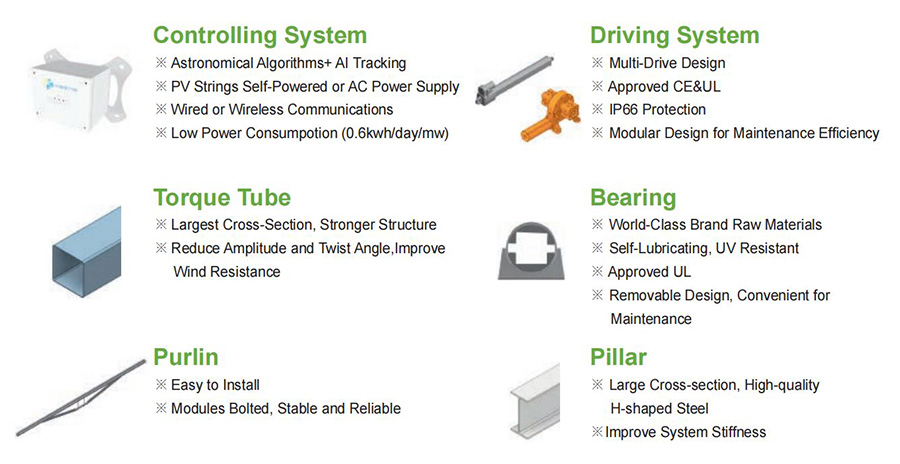

Main Structure components

CPP Wind Tunnel Test

Wintop established a partnership with CPP, the first American company to provide wind engineering services to architects and engineers. Combining the frequency and characteristics of damping ratio of the WT-tracker tracking system, study the resonance, flutter, gallop, torsional divergence and other results of the WT-tracker system caused by aerodynamics, and analyze the influence and instability during the operation of the system.

Wintop Multi-drive Solar Tracker Advantages:

-

System Damping Ratio is greater

-

Reduce Amplitude on Modules by 50%

-

Reduce the Force on Torque Tube by 50%

-

Reduce the Force on Driving Pillar by 50%

-

Reduce Torsion Angle on Torque Tube by 50%

-

Optimize Wind Resistance System

-

Traditional Single-drive Tracking System

-

WTT Multi-drive Tracking System

Operating Mode

Terrain Adaption

WT-Tracker System

-

Flexible Layout

-

Fully Use Irregular Land, Improve Land Utilization

-

20% N-S Slope

-

Unlimited E-W Slope

Foundation Options

|

Type of

Foundation

|

Steel Piles

|

Concrete with

Steel Piles

|

Poured

Concrete Pile

|

PHC Piles

|

PHC Piles

|

|

Application

|

Soft Ground

|

Soft Ground

|

Gravel

Ground

|

Agriculture PV

Complementary

|

Fishery PV

Complementary

|

|

Connection

Method

|

Direct

Ramming

|

Ramming+Conc

rete

|

Anchor Bolt

Connection

|

Pile-Top Welding

|

Pile-Top Welding

|

Modules Array Proposals

Project