|

Description |

Quartz Stone |

|

Product

Name |

SS3287

Tornado |

|

Color |

Grey |

|

Size |

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc. |

|

Thickness |

15mm, 18mm, 20mm, 30mm. |

|

Surface |

Polished or honed or customized |

|

Water

Absorption |

≤0.04% |

|

Harness |

7 Mohs |

|

MOQ |

100 Square meters |

|

Package |

Packed with strong wooden crates and foam, film inside |

|

Ideal Use |

Countertop, Vanity Top, Sink, Floor and Wall Tiles, Step, Window Sills

etc. |

While granite remains the most popular countertop material among homeowners, there’s a new contender. Quartz is steadily becoming the top choice among homeowners today. Quartz countertops are beautiful, and it is one of the best options for your kitchen.

The benefits of having a quartz countertop include:

• Quartz is a mineral and one of the most abundant on our planet.

• Eye-catching beauty with a wide array of color options and sparkling or veining effect of granite, marble, or other natural stone.

• Quartz Countertops are the hardest of all countertop surfaces.

• Quartz countertops are nonporous; therefore, food and moisture cannot penetrate the surface.

• Quartz is an expertly manufactured high performance countertop surface that is comprised of 93% natural quartz and 7% resin.

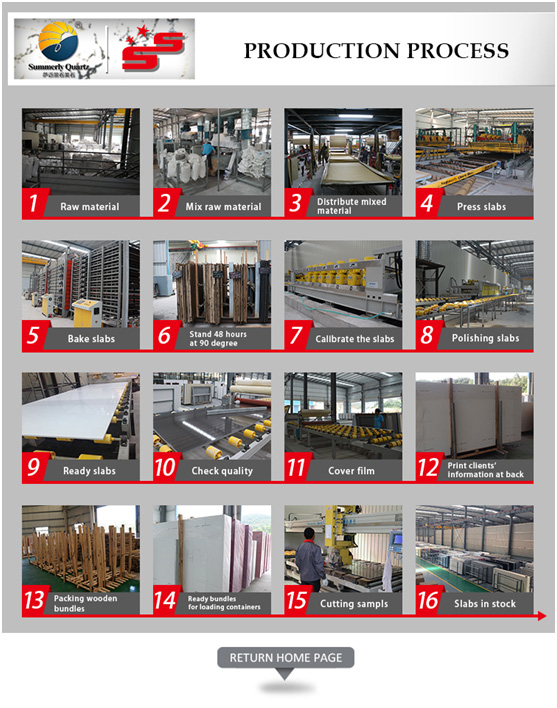

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

Packing: