Economical Warehouse Industrial Heavy Duty Pallet Racking

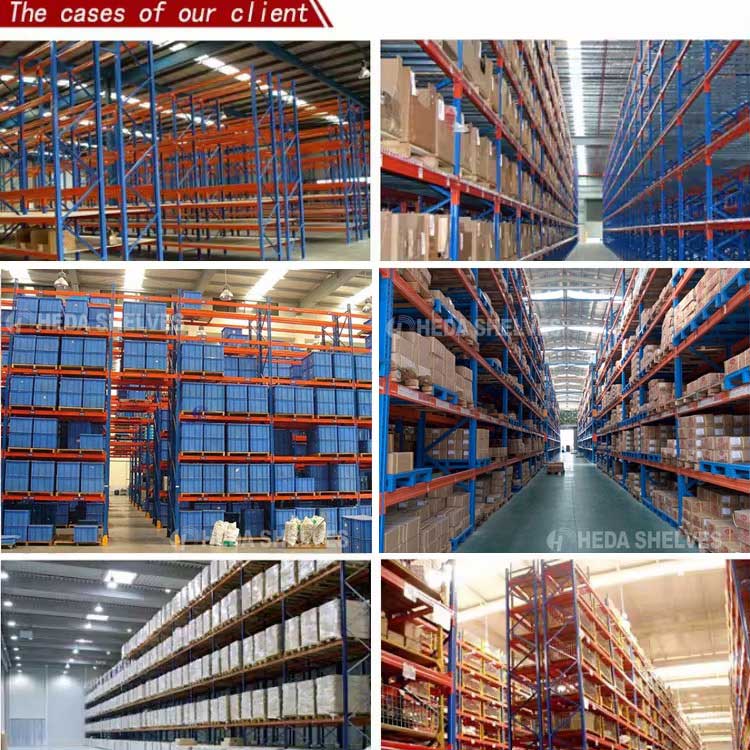

Heavy Duty Pallet Racking, the most favorable cost-saving storage system in warehouses, can be founded in all regions and countries around the world. Heavy Duty Pallet Racking have the characteristics of heavy load-bearing, adjustable height, high selection efficiency, and high space utilization.

Product Parameter

Material:Cold-rolled Steel

Loads Type: Palletized/ multiple items

Loading Capacity:1000~5000kg/layer

Surface:Electrostatic spray surface

Use area:Warehouse, factory, storage place

Heavy Duty Pallet Racking, the most favorable cost-saving storage system in warehouses, can be founded in all regions and countries around the world. However, for many beginners who's not familar with storage and material handling industry, they may find it difficult, even though selective system is relatively simple compared to other storage systems. As one of our best-selling products, we export excellent quality selective pallet rack columns, beams and accessories to more than 100 countries with our one-stop services including consultancy, design, manufacture, installation and maintainence. Turning to professionals for help is always a good choice, while at the same time, we would like to be your information provider by sharing our valuable projects experience for customers who want to learn more.

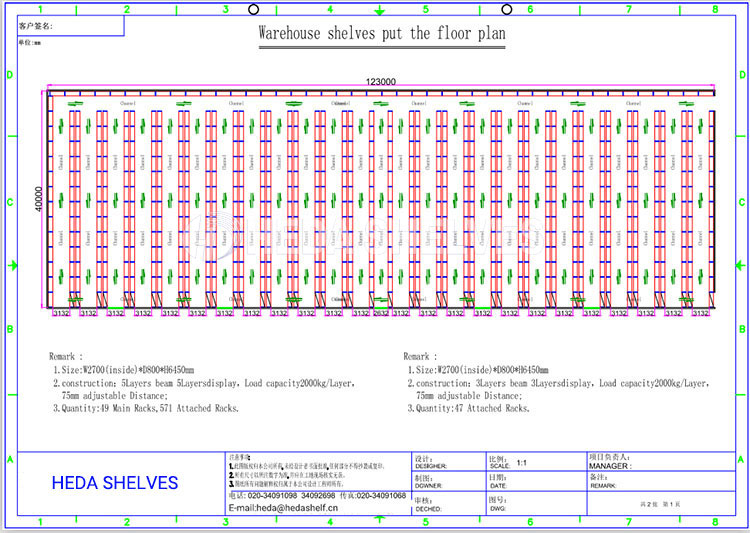

With its great popularity, Heda shelves has finished numerous related cases and now I'll show you a simple one to help you understanding how this whole process works.

-->>Step1: Information collection

When the customers find us and ask for storage solution advices, Heda shelves will discuss with them first and figure out their main requirements. The following was an information form collected from the client.

Information collected from customer:

|

Required Details |

Feedback |

Notes |

|

Warehouse Condition |

Normal temperature |

Need CAD design |

|

Storage Density |

Normal |

No compact solution required |

|

Loads Type |

Palletized/ multiple items |

Pallet rack |

|

Loading Capacity |

1000~2000kg/layer |

Heavy duty |

|

Material Handling Method |

Standard pallet truck |

Aisle width:3~4m |

|

Stock Rotation |

Fast |

FIFO |

|

Selectivity |

100% |

Selective pallet rack |

|

Accessibility |

Instant |

Direct handling end |

|

Operation |

Easy |

Standard forklift |

|

Cost |

Cost-effective |

Common type |

|

Maintenance |

Easy and low cost |

Simple structure |

-->>Step2: Proper storage solution selection

-->>Step3: Project details confirmation

Confirmed the design drawing with our clients then made some adjustments to their satisfaction. Then our engineer chose proper material type and size for this Heavy Duty Pallet Racking that are functional, safe and cost-saving.

To be noted that all the Economical Pallet Racking manufactured by heda shelves are using high quality cold rolled steel purchased in large national steel plant. And all our professional engineers are trained with rich experience and always put rack safety at the first position. Then we offered our best quotation to our clients considering purchasing quantity and raw material market.

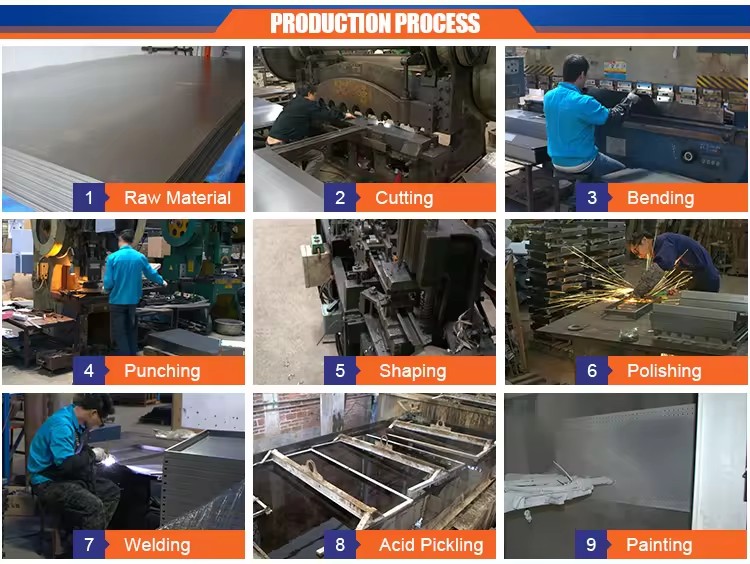

-->>Step4: Order placement and production

Our client was satisfied with our price and service, then signed the contract very fast. After payment, we started the production process.Our manufacture procedures are indicated as follows:Raw-material- →Cutting- →Bending- →Punching- >Shaping-→Polishing-→Welding-→Acid Pickling-→Painting-→Finished products.

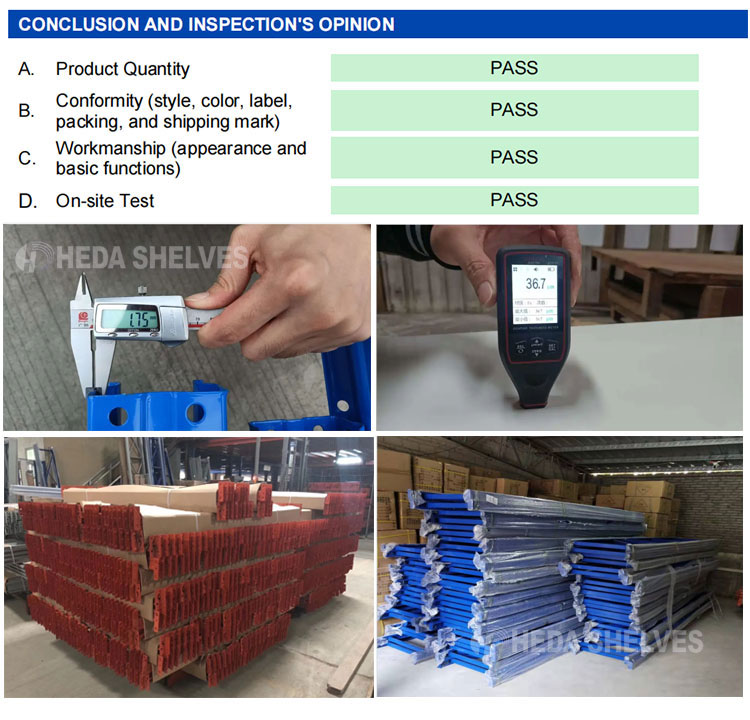

-->>Step5: Quality management

Heda shelves can't emphasis more on product quality and carries out strict quality management from raw materials purchasing to the whole manufacture procedures. Before dispatched from the factory, a whole series of factory examination regulation of racks will be followed for quality guarantee. Besides, a third party quality test is available as our customers' personal request.

-->>Step6: Package and shippment

-->>Step7: Installation support and examination

Some clients used to have concerns about the installation step until they deal businesses with Heda shelves. Taken all these issues into consideration, Heda shelves provides detailed project installation support varying from assembly drawings and videos to installation engineers' specific instruction via Internet or onto the project site personally.

-->>Step8: After-sale services

Heda shelves Company Information