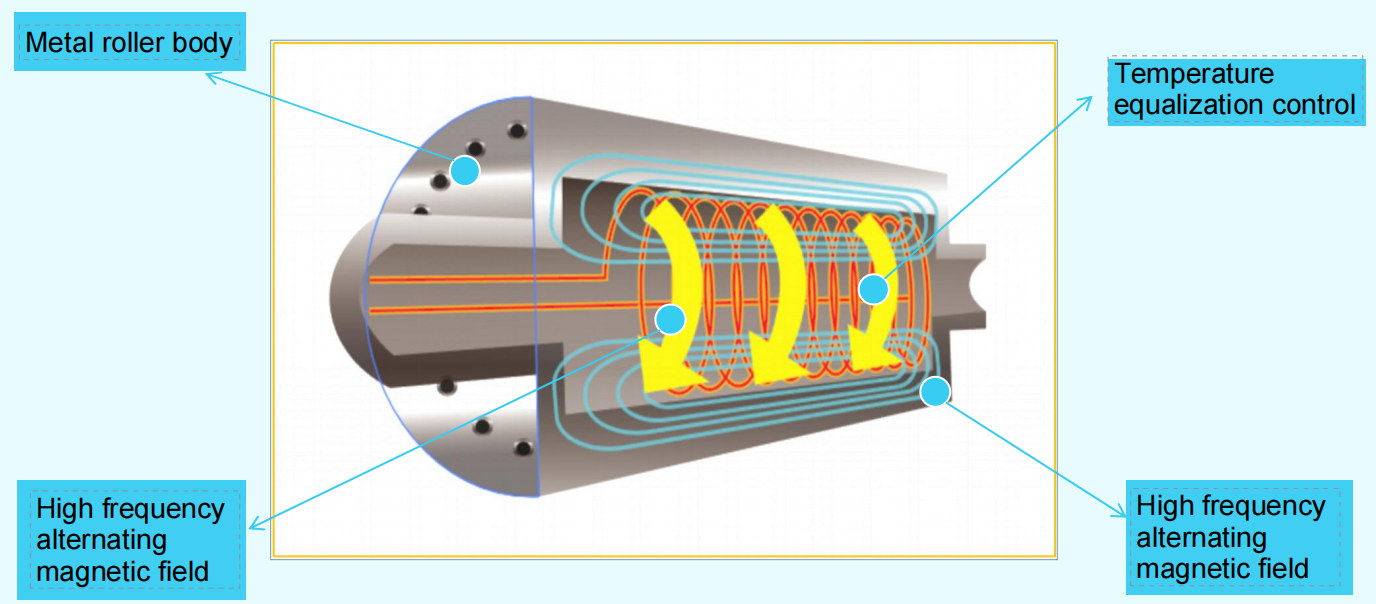

Heating principle of electromagnetic heating roller

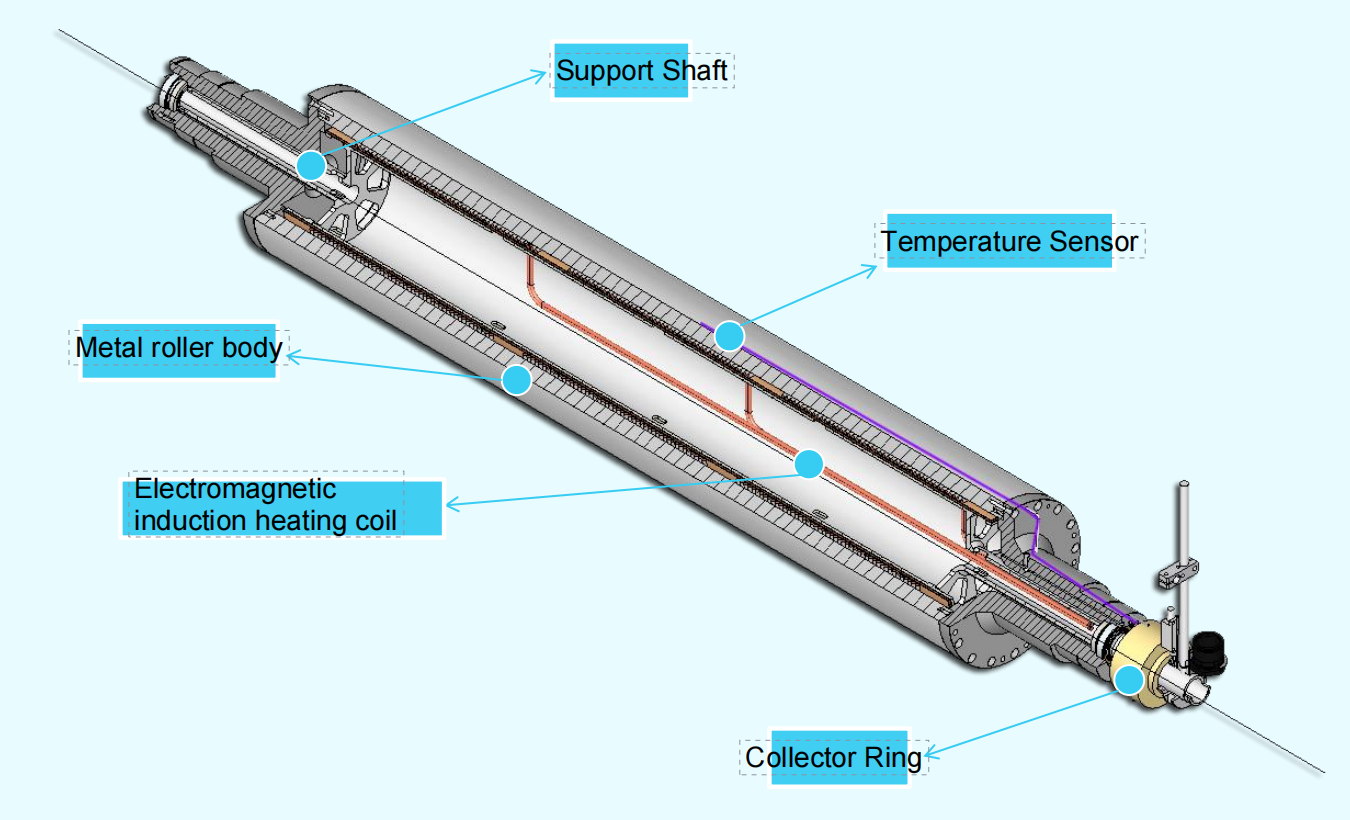

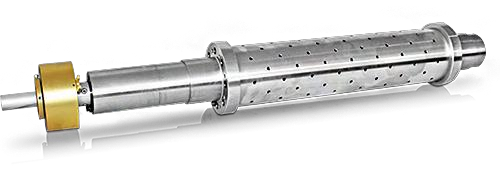

Internal basic structure of Electromagnetic heating roller

Main classification of electromagnetic heating roller

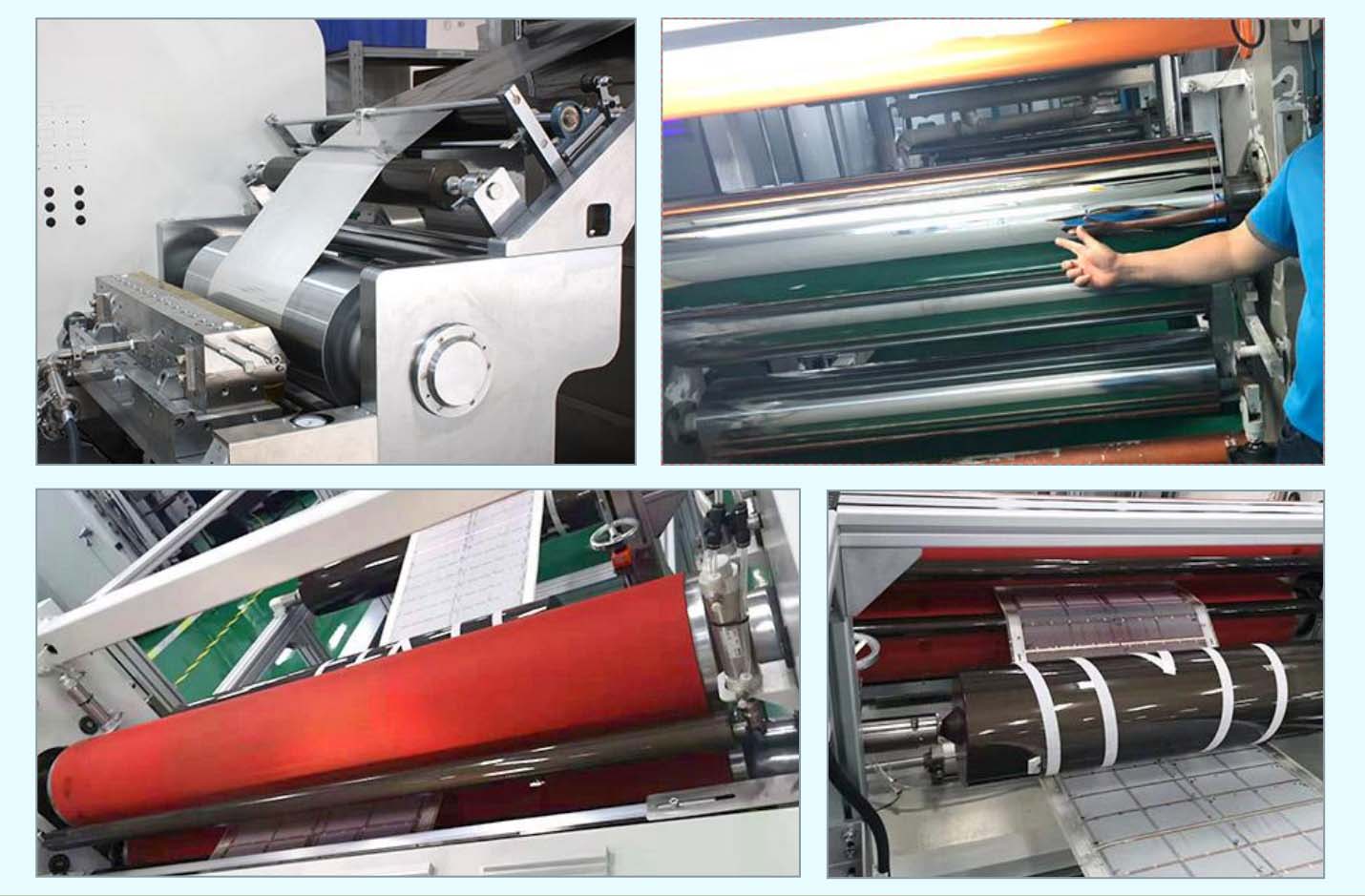

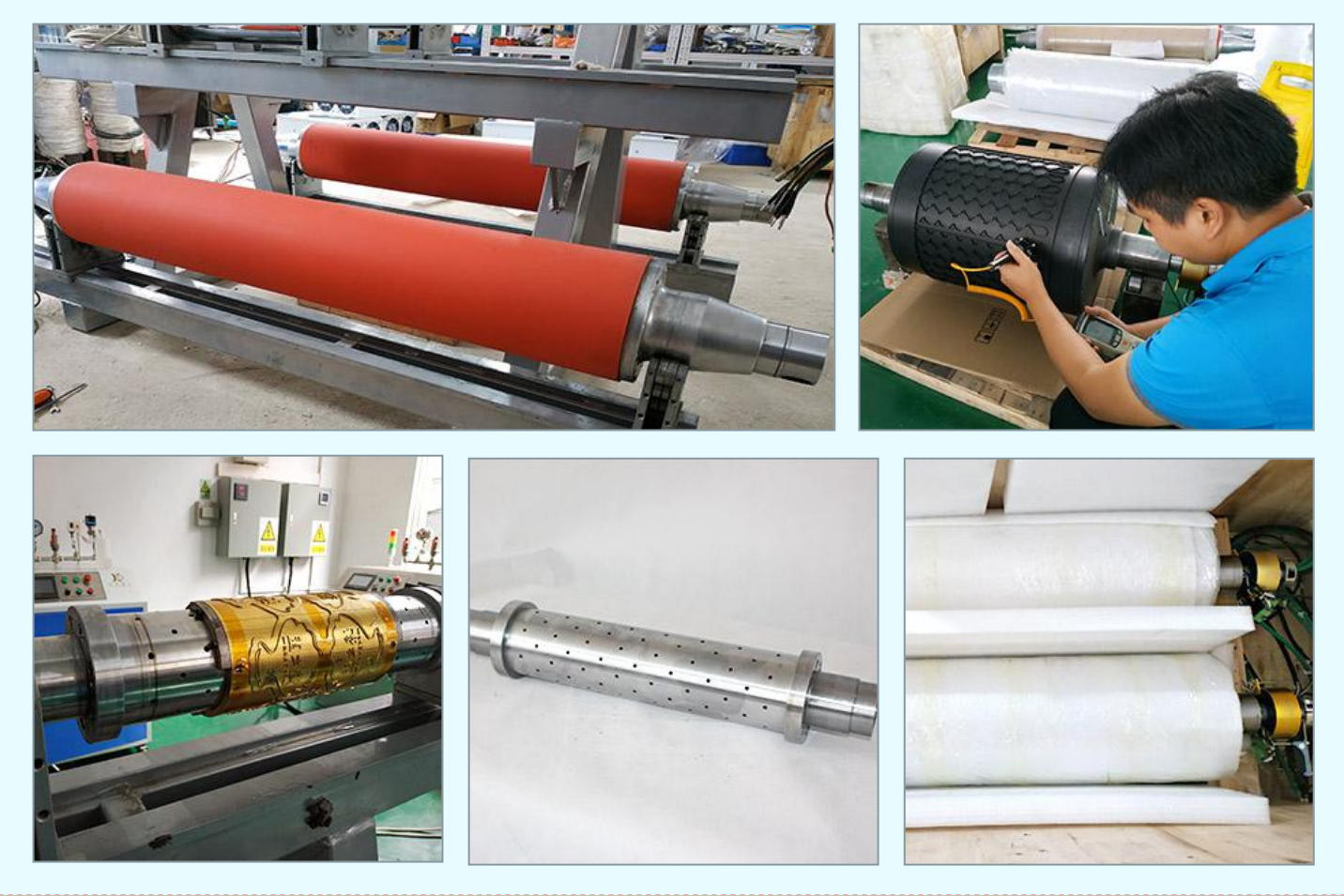

I.Compound Roller

【Process description】:

In the production process of composite materials, the temperature needs to be precisely controlled according to the characteristics of composite materials and adhesives.

The electromagnetic induction heating roller can keep the temperature difference of the surface temperature of the roller body within +1°C in a large temperature range, which can make polyester, polyethylene and polypropylene etc.the polymer film and aluminum foil, paper, iron plate and other dissimilar materials are perfectly bonded to produce a variety of composite materials.

【Application field】:

Liquid crystal panels, aluminum-plastic composite panels, food containers, electronic products materials (PCB, lead rack), plastic greenhouses and other agricultural and industrial materials food cans, beverage cans, washing machines, refrigerators and other home appliance materials, automotive interior materials, other packaging materials and materials composite.

II. Moulding Roller

【Process description】:

In all kinds of high-grade tobacco, alcohol, capsule shell, cosmetics and other packaging materials processing, usually need to use anti-counterfeiting printing technology, molding roller is the core component of anti-counterfeiting printing machine, our company produced electromagnetic heating molding roller series products cover temperature uniform single plate roller. Energy consumption is reduced by 50%-70% compared with traditional thermal oil or electric heat pipe.

【Application field】:

Air Bubble bag packaging rolling, capsule packaging rolling, various plastic materials rolling shape.

III. Gold / Silver Stamping Roller

【Process description】:

Used in the packaging industry, and the leather industry, the efficiency is 10 times faster than the traditional up-and-down ironing silver, and the efficiency is greatly increased.

【Application field】:

Packaging and printing industry, leather goods industry and other industries that need hot gold and silver stamping.

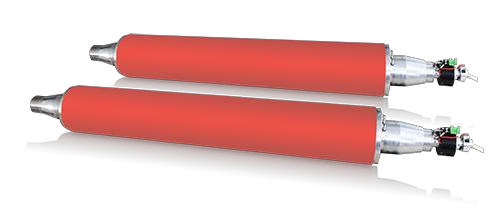

IV. Electromagnetic heating roller with silicone coated

【Process description】:

Used for upper and lower composite, uniform temperature, high efficiency and energy saving, fast heating speed.

【Application field】:

Various materials composite industry.

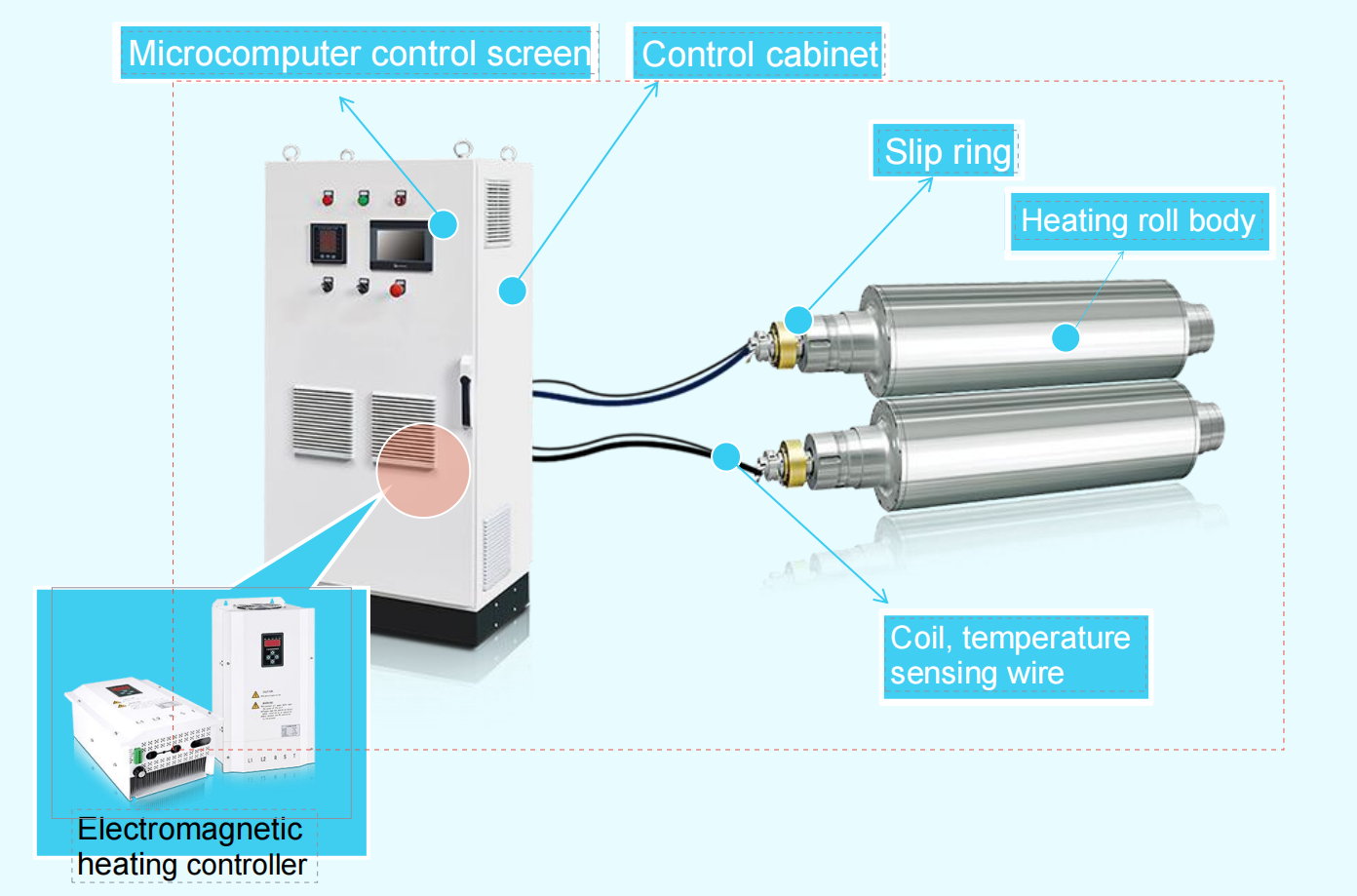

Electromagnetic heating roller main configuration

[The main accessories are as follows] :

1. Roller 2. Electromagnetic heating mandrel 3. Slip ring 4. Electric cabinet 5. Air switch 6. Contactor 7. Delta PLC and temperature control module

8. Weylon touch screen 9. Izumi button and indicator light and other electrical accessories 10. Temperature sensor 11. Electromagnetic heating controller

Comparison of electromagnetic heating roller with other traditional heating rollers

! ! Performance advantage comparison ! !

| Comparison factors |

Thermal oil roller |

Electric heating tube roller |

Steam heating roller |

Electromagnetic heating roller |

| Heating medium |

Heat transfer oil |

Electric heating tube |

Hot steam |

Electromagnetic field |

| Thermal energy utilization rate (η) |

70% |

80% |

70% |

96% |

| maximum roller surface temperature ℃ |

280 |

350 |

180 |

420 |

| Roller surface temperature uniformity ℃ |

±10

|

±18

|

±6

|

±1

|

| Temperature control accuracy ℃ |

±4

|

±10

|

±4

|

±1

|

| Heating speed |

Slow (Heating 200 ° C required 30-50 minutes) |

Slow (Heating 200 ° C required 30-40 minutes) |

Slow (Heating 200 ° C required 30-40 minutes) |

Fast (Heating 200 ° C required only 18-20 minutes) |

| Reheating speed |

Slow |

Slow |

Slow |

Fast |

| Working environment |

oil pollution, odor |

Relatively clean |

Gas and water cost |

Clean, pollution-free, silent |

| Production risk |

Heat conduction oil leaks, flammable |

More dangerous, easy to leak electricity |

Need to install a boiler, easy to leak air |

No leakage, no direct contact with electrical, safe |

| Post-maintenance |

Disassembly pipeline is complicated |

Replace the electric heat pipe frequently |

Disassembly pipeline is complicated |

Electrification automatic control, intelligent, simple, no maintenance later |

| Operating performance |

oil circuit is easy to block and coking |

Temperature is difficult to control |

Easy to leak gas and produce scale |

Man-machine interface visual operation |

| Service life (years) |

3~5 |

3~5 |

3~5 |

More than 10 |

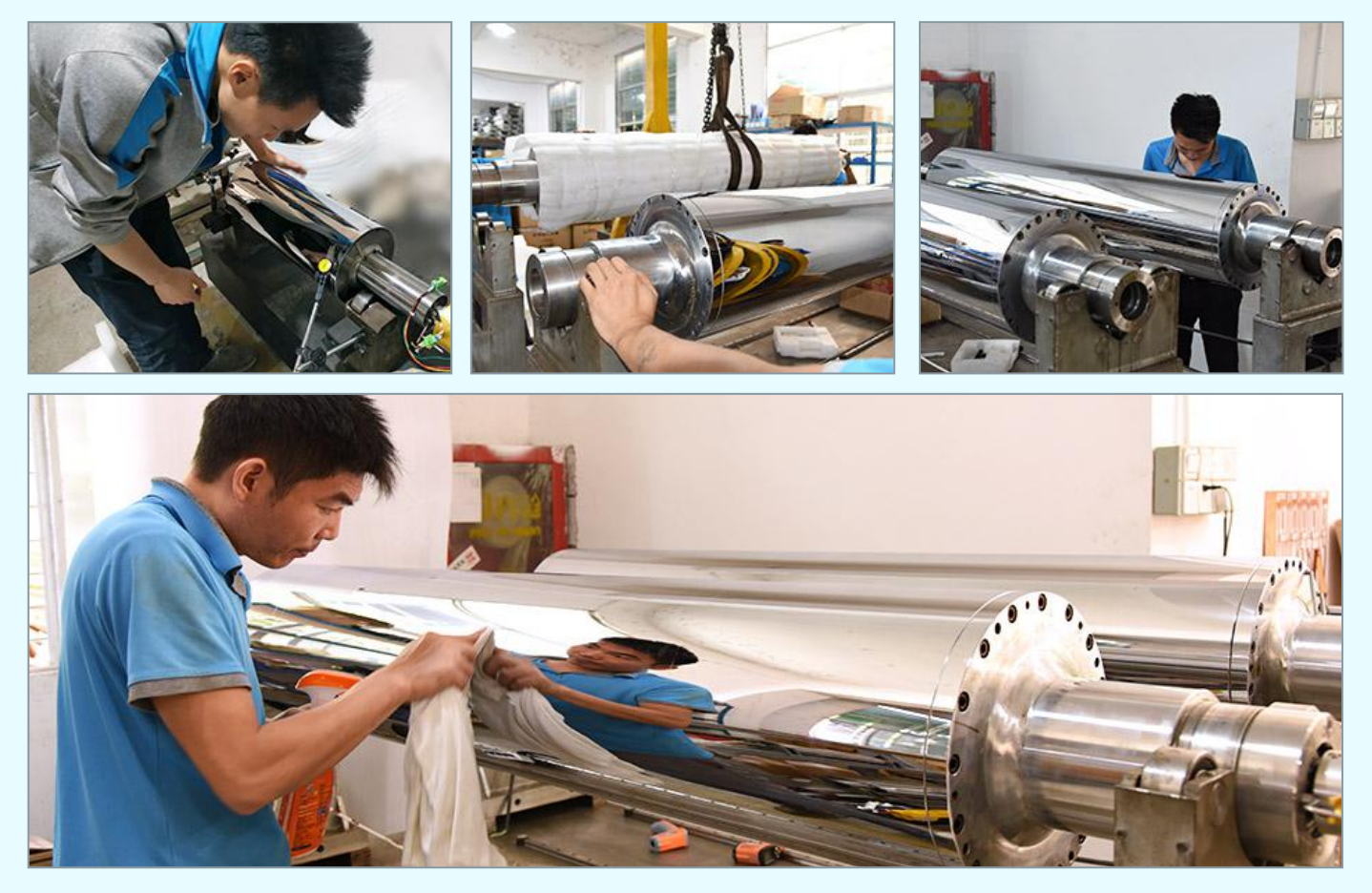

Workshop

Application Case