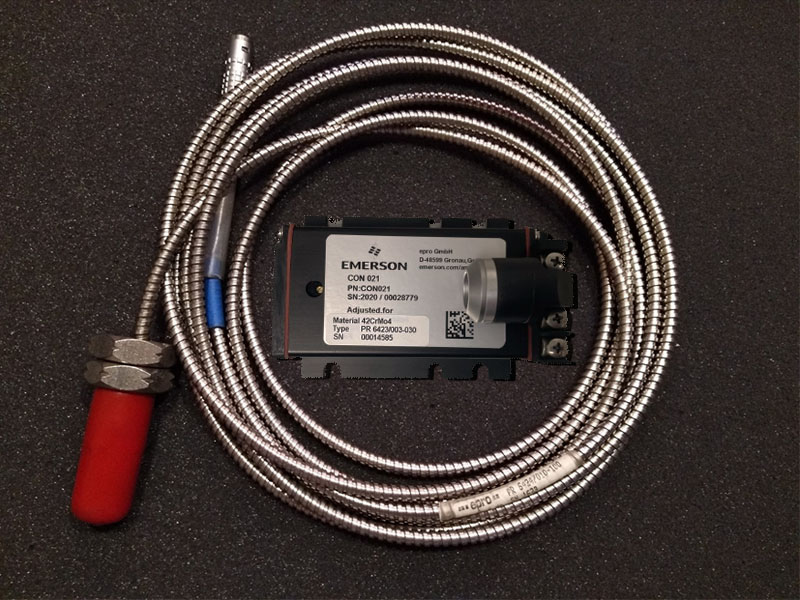

EPRO PR6424/006-030 16mm Eddy Current Sensor

Function principle and design:

Together with the signal converter CON 0.. the PR6424/006-030 eddy current sensor forms an electric oscillator whose amplitude is damped by the approach of metallic targets in front of the sensor head.

The damping coefficient is proportional to the distance between transducer and measuring target.

Upon delivery, the sensor could be adjusted to the converter and to the measuring material, thus there is no additional adjustment work necessary for the installation.

Only the initial air-gap between transducer and measuring target must be adjusted to get the correct signal at the output of the converter.

Applications

Measuring systems with eddy current transducers serve the measurement of mechanical quantities, such as shaft vibration and shaft displacement. Applications with such systems can be found in different industrial areas and laboratories.

Due to the contactless measuring principle, small dimensions, a rugged construction and the endurance against aggressive media, this type of sensor is optimally suitable for the use at all kind of turbines.

epro offers a wide range of devices for measuring and monitoring.

Measuring quantities are e.g.:

- Air-gaps between rotating and stationary parts

- Vibrations of machine shafts and housing parts

- Shaft-dynamic and eccentricity

- Deformation and deflection of machine parts

- Axial and radial shaft displacement

- Abrasion and position measurements at thrust bearings

- Thickness of oil film in bearings

- Differential expansion

- Housing expansion

- Valve position

Construction and dimensions of measuring amplifier and relevant sensors apply to international standards, e.g. API 670, DIN 45670 and ISO10817-1.

At connection via safety barriers, sensors and signal converters may also be operated in hazardous areas. The certificate of conformity according to the European standard EN 50014/50020 has been submitted.

| Dynamic Performance |

| Sensitivity/Linearity |

4 V/mm (101.6 mV/mil) ≤ ±1.5% |

| Air Gap (Center) |

Approx. 2.7 mm (0.11”) Nominal |

| Long Term Drift |

< 0.3% |

Range: Static

Dynamic |

±2.0 mm (0.079”)

0 to 1,000μm (0 to 0.039”) |

| Target |

| Target/Surface Material |

Ferromagnetic Steel

(42 Cr Mo4 Standard) |

| Maximum Surface Speed |

2,500 m/s (98,425 ips) |

| Shaft Diameter |

≥80mm |

| Environmental |

| Protection Class |

IP66, IEC 60529 |

| Operating Temperature Range |

-35 to 150°C (-31 to 302°F) |

| Temperature Error |

<4%/100°K (API 670 Compliant) |

| Pressure Resistance to Sensor Head |

10,000 hPa (145 psi) |

| Shock and Vibration |

5g @ 60Hz @ 25°C (77°F) |

| Physical |

| Material |

Sleeve – Stainless Steel, Cable – PTFE |

| Weight (Sensor & 1M Cable, no Armor) |

~200 grams (7.05 oz) |

100% brand new and original,All the goods will be tested before shipment.

For the in stock items, we will send the order out within 5-7 days after receive the payment.

Global supplier of quality automation and control components.

Topteng offers a 12-month warranty from the date of delivery.

In the event of non-conforming product ( if damaged or incorrect product is received ),

Any nonconformity must be reported within 7 days of receipt of goods.

Questions? Call +86 18050017653 or Email sales4@nseauto.com