Product name:High performance granite polishing machine

Product specifications

|

Description

|

Unit

|

ZDMJ-12 RS

|

ZDMJ-16 RS

|

ZDMJ-20 RS

|

ZDMJ-24 RS

|

|

Power of main motor(Optional)

|

KW

|

11/15

|

11/15

|

11/15

|

11/15

|

|

Max. processing width(Optional)

|

MM

|

2200

|

2200

|

2200

|

2200

|

|

Processing height

|

MM

|

10-60

|

10-60

|

10-60

|

10-60

|

|

Conveyor belt running speed

|

M/MIN

|

0-4

|

0-4

|

0-4

|

0-4

|

|

Number of polishing head(optional)

|

PCS

|

12

|

16

|

20

|

24

|

|

Water consumption

|

M³/H

|

15

|

19

|

23

|

27

|

|

Total power

|

KW

|

157/205

|

201/265

|

245/325

|

289/385

|

|

Dimension(L×W×H)

|

MM

|

9800*3100*2700

|

11800*3100*2700

|

15000*3100*2700

|

17000*3100*2700

|

|

Weight of machine

|

KGS

|

26500

|

29500

|

34500

|

36500

|

|

Note:Customers can choose the number of polishing heads and polishing height according to their requirements

|

Product features

|

Machine structures

|

|

|

|

|

|

|

Basement with interchangeable plates

|

Pneumatic lifting system

|

Spindle carrying bridge

|

1)The base of WEIYE granite disk line polishing machine is made by high-strength steel,and is processed by large CNC machine center,to reduce the vibration and polishing noise,get better operation experience and polishing quality in a long using life.

2)After a long time wear,machines table is extremely vulnerable to damage by conveyor belt long time sliding.In order to avoid this situation,WEIYE adopts special interchangeable iron plates to reinforced tables surface.

|

Polishing heads rise and fall rely on one set of pneumatic lifting system what is built by WEIYE engineers.This pneumatic system assembles with air cylinder,air pressure valve ,solenoid valve and special lifting shaft etc.Under the perfect match,the polishing heads can be flexibly raised and dropped.Ensure slabs can be polished into good quality with high efficiency.

|

In order to keep maximum equilibrium to the polishing heads and to prevent any vibrations of spindle carrying bridge,WEIYE choose whole piece of 2.5mm thick steel weld into spindle carrying bridge.In the use of materials, WEIYE never hesitate ,always try the best possibility to ensure the durability, safety and stability of the machine .

|

|

Electrical configuration

|

|

|

|

|

|

Power panel

|

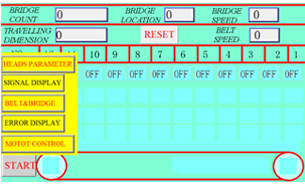

Program page

|

Control panel

|

|

Power panel is the soul of whole machine,it gives vitality to the machine.So the quality of the machine is closely related to the quality of electronic control accessories,WEIYE attaches great importance to the quality of electrical spare parts.Consistent for decades,all kinds of WEIYE machines are equipped with the international first class accessroies,such as Schneider,Fuji and Mitsubishi etc.

|

1) Program is the master of whole machine,a good system can make machine runs better,more stable and smooth .WEIYE program was completely independent designed ,well-tested in the market.Upgrade year after year,WEIYE system is currently one of the most widely used operating systems on the market.

2) WEIYE system integrates supervision, intelligence, and convenient interaction.The operator can observe the running status of the machine in real time, there is no delay in human-computer interaction, and the machine will respond immediately if any operation instruction is issued

3) This system can automatically detect the shape of the slabs, regardless of whether the edge shape of the slabs are regular or not, the machine can determine the best polishing plan in time and implement it.

|

WEIYE automatic polishing machine is equipped with a touch screen control panel,with user friendly interface,which the operator can interact in an extremely intuitive way by using clear screens which represent the machine or a portion of it. All the work parameters of the machine can be consulted in real time.

|

Our advantage

1) The Chinese manufacturer with the largest annual output and export of granite polishing machine.

2) We exported line polishing machine to many countries, such as India, Italy, Mexico, Poland, Algeria, etc.

Quality service

We provide free installation service and one year warranty time to our customers.

Packaging and shipment

Waterproof plastic film, well fixed in container or bulk carrier suitable for long transportation.

FAQ

Q:When is the delivery time.

A:Normally 30-40 days after deposit received,if need urgent,can be negotiated further.

Q:How about the machine using life.

A:Under normal use and maintenance,no deliberate damage,machine can be used over 10 years.

Q:What is the difference between disk line polishing machine and fickert polishing machine .

A:Fikcert line polishing machine is especially used in polishing big granite slabs which slab width is over 1.8m,and disk polishing machine is normally used to polish small slabs which slab width is less in 1.3m.The above conclusion is not absolute, customers can choose the most suitable model according to their own needs.