Specification of aluminum polishing nanopowder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

MP13-50N

|

50nm

|

99.9

|

20

|

0.1

|

2.7

|

Spherical

|

black

|

MP13-100N

|

100nm

|

99.9

|

15

|

2

|

2.7

|

Spherical

|

black

|

MP13-1U

|

1-3um

|

99.9

|

9

|

4.2

|

2.7

|

Spherical

|

grey black

|

Note: We can supply different size products of aluminum polishing nanopowder according to client's requirements.

The nano aluminum powder has high purity, uniform particle size distribution and easy to disperse.

Application of aluminum polishing nanopowder:

1. High-efficiency catalyst: greatly improve fuel burning speed and improve combustion stability;

2. Activate the sintering additive to reduce the sintering temperature and increase the density and thermal conductivity of the sintered body;

3. Surface conductive coating treatment of metal and scrap metal: microelectronic device coating is carried out under anaerobic conditions and below the melting point of the powder;

4. Conductive film layer, preparation of polishing paste, and the like.

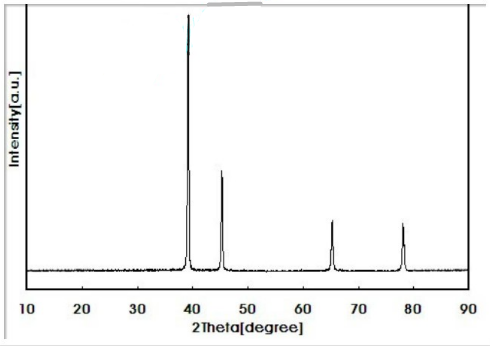

SEM & XRD of aluminum polishing nanopowder:

Storage conditions:

aluminum polishing nanopowder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.