High Temperature Resistant Silicone Sheet Coil Insulation Silicone Board

- GMARK manufactures the broadest and deepest selection of sealing solutions on the market. Within these categories, we have thousands of sizes, styles and formulations to choose from.

Product Description

- We specialize in premium materials and grades designed for industrial applications. We stock coils, sheets, rods, strips, films, ropes, rods, tubes and balls in all sizes. We can manufacture custom sizes and shapes, add adhesive and deliver finished products within days.

Product Use

- Hardness range: Shore hardness 5A-50A, conventional is 15A.

- Special-shaped rubber strip: according to customer needs, customize different shapes.

- Dimensional tolerance: conventional size +/-1mm, some dimensional tolerances can be +/-0.5mm.

- Temperature resistance range: from -50℃ to 280℃, 380 degree high temperature resistance can be customized specially.

- Value-added services: The surface can be bonded, cut, added with LOGO, and glued according to customer needs.

- Product certificate: SGS, ROHS and other related environmental safety test reports, tasteless.

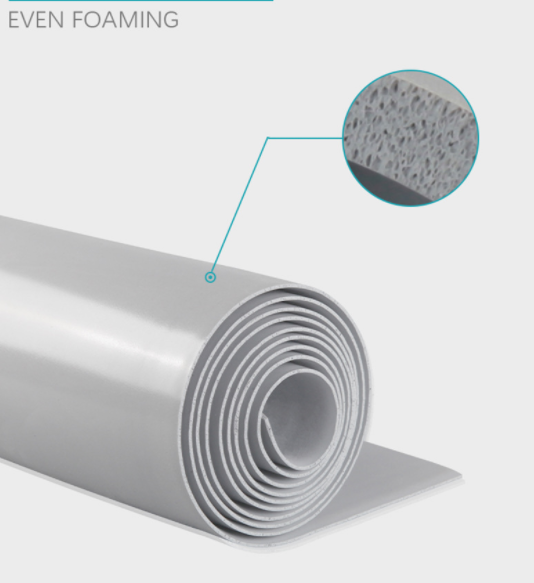

- Product performance: The silicone foam sheet belongs to the molding process and is pressed by a large molding machine. Because it is like a sponge, it is generally called a silicone sponge sheet, and the silicone foam sheet mainly plays a role in sealing, temperature resistance, and It is called temperature-resistant silicone foam sealing sheet. Compression deformation resistance, durable, can ensure long-term shock protection of accessories; small surface tolerance, diameter tolerance ± 0.3mm, uniform foam density; environmental protection, insulation, high temperature resistance, compression resistance, strong resilience.

Physical Properties

| NO. |

Test Item |

Test Method |

Result |

Conclusion |

| 1 |

Compression Deflection |

ASTM D1056-14Section 17~23 |

12.7psi |

/ |

| 2 |

Compression Set |

With reference to ASTMD1056-14 Section50~56 and client's requirement |

4% |

/ |

| 3 |

Density |

With reference to ASTM D792-13 Method Band client's requirement |

0.385g/cm3 |

/ |

| 4 |

Dielectric Strength |

GB/T 1695-2005 |

5.51kV/mm |

/ |

| 5 |

Low TemperatureResistance Test |

Provided by client |

No damage |

/ |

| 6 |

Tensile Test |

With reference to ASTM D412-16 Method A and client's requirement |

| Tensile Test |

0.651MPa |

| Elongation at Break |

230% |

|

/ |

| 7 |

Volume Resistivity |

GB/T1692-2008 |

4.23x1016Ω·cm |

/ |

| 8 |

Water Absorption |

ASTMD570-98(2018) |

0.68% |

/ |

How to contact

How to contact

Tel: +86-17803901720

Email:contact@gmarktape.com

Please scan the QR code and add me to serve you!