Screw Chiller

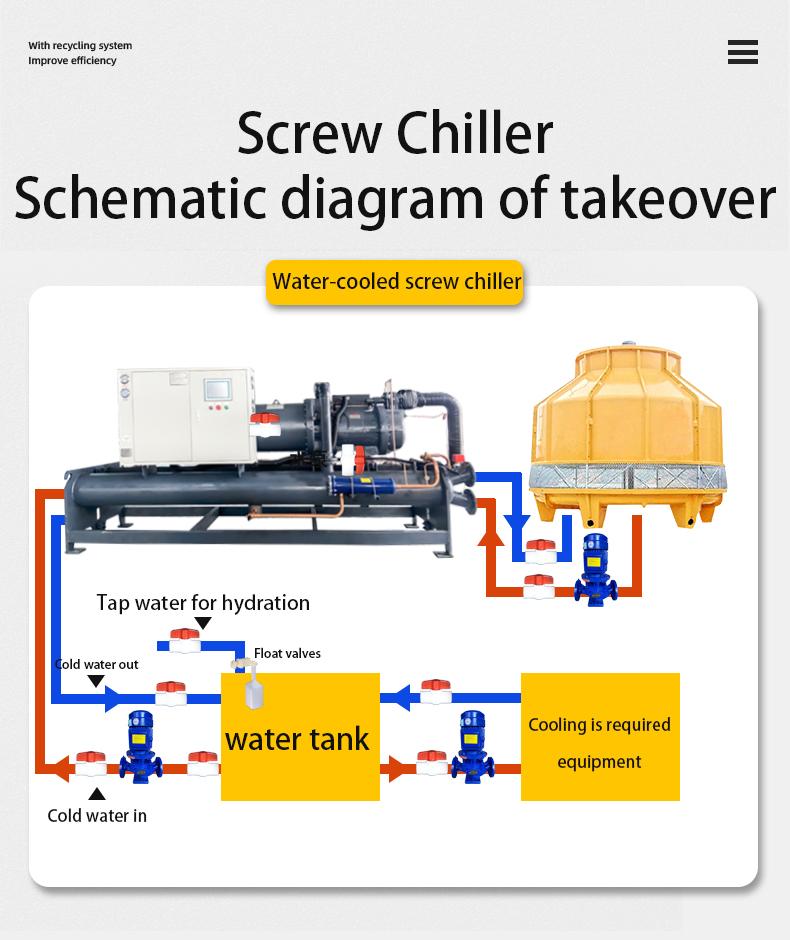

The working principle of the screw chiller is based on the refrigeration cycle, which comprises four key processes: compression, condensation, expansion, and evaporation. These processes continuously cycle to provide the desired cooling effect for the user. The chiller is named "screw chiller" because the compressor within the system utilizes a screw-type structure.

Specifically, in this refrigeration cycle:

The evaporator absorbs heat, causing the refrigerant to evaporate from a liquid state into a gaseous state. The compressor then compresses the gaseous refrigerant, increasing its temperature and pressure. The high-temperature, high-pressure gaseous refrigerant enters the condenser, where it releases heat and condenses back into a liquid state. The liquid refrigerant then passes through an expansion valve, where it undergoes a pressure drop and becomes a mixed liquid-gas state. This low-pressure, low-temperature mixed refrigerant enters the evaporator, repeating the cycle of absorbing heat and evaporating.

In addition, screw chillers have the advantages of high reliability, simple maintenance, and low noise. Whether it is a large factory or a small and medium-sized commercial space, you can choose the right unit size according to your actual needs.

With excellent performance and wide applicability, screw chillers have become a leader in the field of refrigeration and are favored by users. As an energy-saving, environmentally friendly and convenient refrigeration equipment, it will surely play an important role in the future.

Key Features:

1.Exclusive Customization:

We will tailor different HP screw chillers for you according to the needs of customers, and the price required for different HP will be different.

2. High energy efficiency: Spiral compressors have high working efficiency, which can make better use of energy, thereby reducing operating costs.

3. High reliability: The main components of high quality, such as bearings, oil pumps, etc., are used to ensure the smooth operation of the screw compressor and reduce the occurrence of failures.

4. Simple maintenance: Compared with piston compressors, the structure of screw compressors is simpler and more compact, and daily maintenance and overhaul are more convenient and fast.

5. Low noise: The unique screw compression structure and perfect sound insulation design can greatly reduce the operating noise of the unit and improve the comfort of use.

6. Widely applicable: It can be widely used in industrial refrigeration, commercial air conditioning, pharmaceutical, refrigeration and other fields to meet the customized needs of different customers.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?

You can contact us by email about your order details, or place order online.

3) What's the order procedure?

We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?

Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you all paper you need.