Specification of MgO nanopowder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

OP1208-40N

|

40nm

|

99.9

|

30

|

0.74

|

3.6

|

Spherical

|

white

|

OP1208-1U

|

1-3um

|

99.9

|

12

|

1.24

|

3.6

|

Spherical

|

white

|

Note: We can supply different size products of MgO nanopowder according to client's requirements.

1. The product has high purity, small particle size, uniform distribution, large specific surface area, high surface activity, and low bulk density;

2. high purity, low impurity content, with spherical and high specific surface area and other characteristics, in line with the requirements of electronic grade powder materials, can be widely used in electrical, chemical and alloy materials.

Application of MgO nanopowder:

1. Adsorbents and catalysts: Nano-magnesia has a large specific surface area and is an important raw material for the preparation of highly functional and fine inorganic materials, electronic components, inks, and harmful gas adsorbents;

2. High-performance ceramics: Nano-magnesia has good sintering properties. It is not necessary to use sintering aids to achieve low-temperature sintering to produce high-density fine-grained ceramics or multi-functional magnesium oxide films, which are expected to be developed as cutting-edge materials under harsh conditions such as high temperature and high corrosion;

3. Absorbing materials: Due to its high activity and high dispersibility, nano magnesium oxide is easily compounded with polymers or other materials. This kind of composite material has good microwave absorption performance, and at the same time it will not reduce the indexes such as strength and toughness of raw materials, but also add fibrous magnesium oxide to reinforce the effect;

4. Coatings, plastics, rubber and other fillers: Nano-magnesium oxide, due to its high degree of dispersion, can be used as a filler for paints, papers and cosmetics, fillers and reinforcing agents for plastics and rubber, and auxiliary materials for various electronic materials.

5. Flame Retardant Material: Nano-magnesium oxide has a good flame-retardant effect, and it can be used together with sawdust and shavings to manufacture refractories such as light weight, sound insulation, thermal insulation, fire-resisting fiberboard, and cermets. Fireproof coating, adding 0.3-3%, good effect;

6. The nano-composite ceramic additive prepared by sintering together with nano-alumina, nano-titanium dioxide, etc. can replace the noble metal nickel to prepare the heat-resistant steel. Among them, nano-magnesium oxide for fine ceramics is recommended to add 3 to 15%;

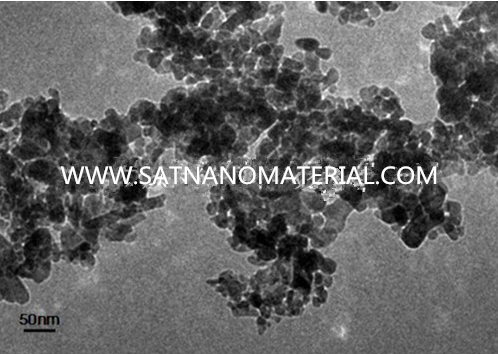

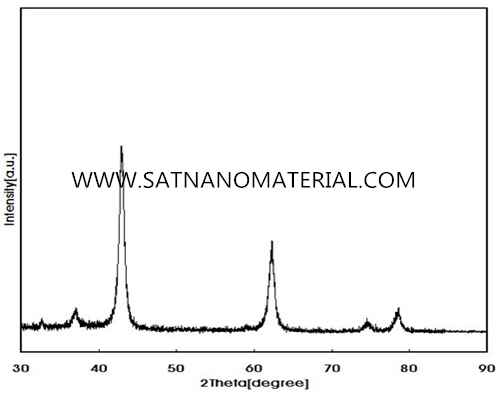

SEM & XRD of MgO nanopowder:

Storage conditions:

MgO nanopowder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.