Powerful Crusher

The power crusher has an inlet, a crushing chamber, a rotary cutting tool, a screen, an outlet and a drive.

Its working principle is to feed the material to be crushed into the crushing chamber through the feed port, and under the action of a high-speed rotating cutting tool, it is crushed into smaller particles. The crushed material is screened through a sieve, and the material that meets the particle size requirements is discharged from the discharge port, while the material that does not meet the requirements continues to be crushed in the chamber.

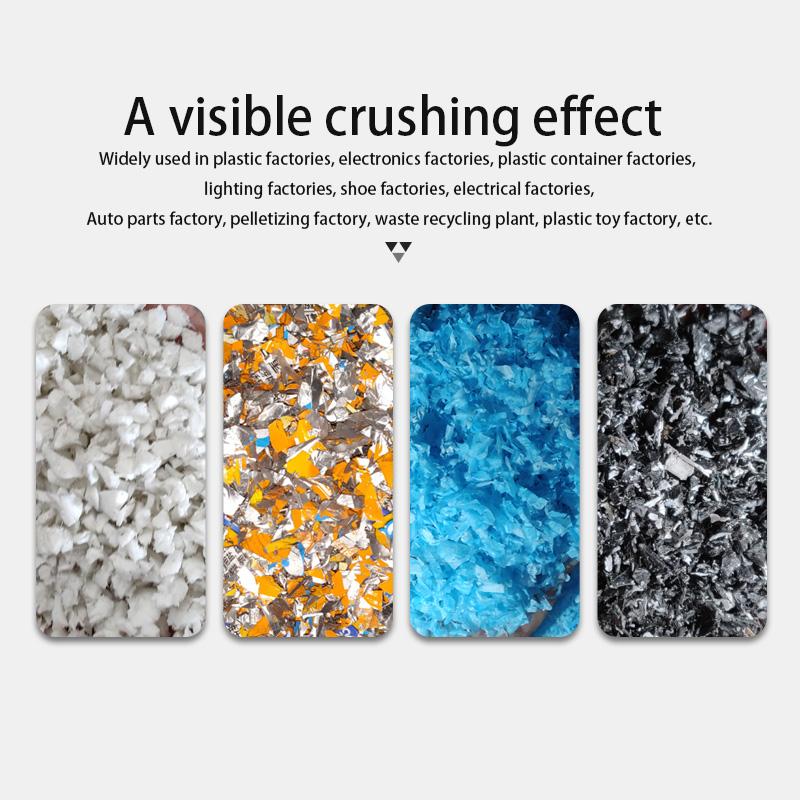

It is suitable for the crushing and reuse of various plastics, especially for various hard plastics (such as material heads, shoe shading materials, etc.), and the effect is better.

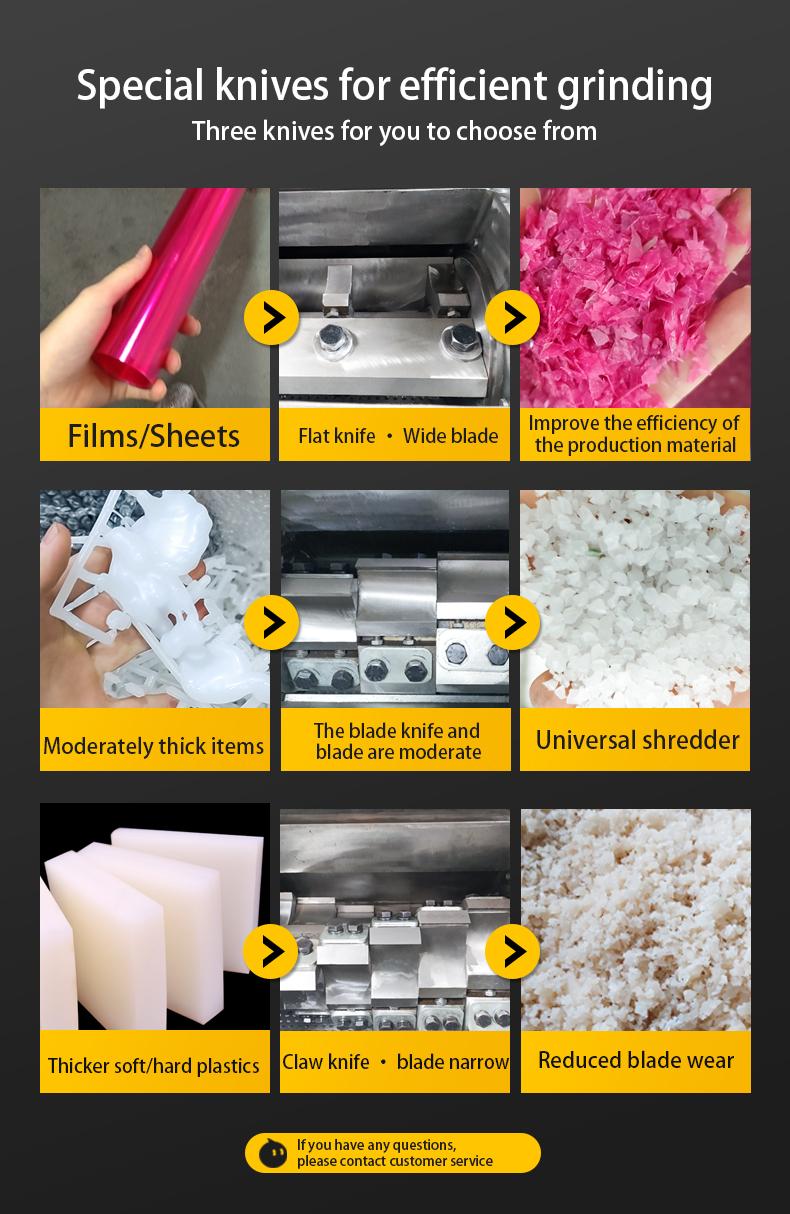

The crusher is simple to operate, and the tool change is simple and fast; The optimized design of the tool holder distributes the claw knife and increases the shear force of each blade, making it suitable for crushing thick materials, hard blocks, material heads, etc., which effectively improves the cutting force of the tool and reduces the wear of the tool. Equipped with electronic control safety design, the hopper adopts a double-layer structure and is filled with sound insulation materials, so that the equipment has good safety, environmental protection, energy saving and durability.

The powerful crusher has the advantages of high crushing efficiency, uniform crushing particle size and wide applicability. It can be used to crush materials of various hardness and properties, such as plastics, rubber, wood, papermaking, traditional Chinese medicine, chemical raw materials, etc. It plays an important role in industrial production and resource production.

Main Features:

1. Exclusive Customization:

We will tailor different models of powerful pulverizers for you according to the needs of customers, and the price required for different power will be different.

2. Efficient crushing

With high-power motor and professional blade design, it can quickly and efficiently crush all kinds of hard materials to the required particle size, which greatly improves production efficiency.

3. Durable and wear-resistant

The body is made of high-quality steel and is equipped with a high-hardness grinding tool to maintain excellent service life and wear performance even when handling strong materials for a long time.

4. Safe and reliable

Equipped with multiple safety mechanisms such as emergency stop switch and overload protection to ensure the stable and reliable operation of the machine, while protecting the safety of operators to the greatest extent.

5. Easy to maintain and clean

The modular design and quick disassembly of major components greatly simplify equipment maintenance and cleaning, reducing downtime.

6. Multi-functional application

Whether it's a wide range of hard materials such as metals, ores, plastics or wood, this powerful shredder can easily handle the crushing needs of different industries.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?

You can contact us by email about your order details, or place order online.

3) What's the order procedure?

We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?

Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you all paper you need.