Equipment Composition of the System

3.2.1 Equipment Composition of the System

Server, workstation, on-site touch screen control, mobile(iPad) and other handheld devices, smart centralized controllers (or gateways), loop switch controllers, loop dimming controllers, single-lamp smart lighting management terminals, dual-lamp smart lighting management Terminal, dual-colors(2700K~6000K) intelligent lighting management terminal, dual-mode(hybrid of PLC+LoRa) intelligent lighting management terminal, multi-functional intelligent lighting management terminal, smart panel switch, illuminance meter (or brightness meter), motion sensor, linkage sensor, gas sensor, weather sensor, etc., and emergency Or supporting professional equipment (repeaters, copy controllers, monitors, debugging equipment, etc.).

Generally speaking, the system are divided into cloud management center equipment, human-machine interface equipment, local management center equipment, lighting fixture control equipment, sensor equipment, and debugging equipment.

3.2.2 Cloud Management Center Equipment

The core of cloud management center is system software, hardware carrier is server or server group. The cloud management center relies on the private cloud platform to collect the needed information, integrates through the big data component, uses the data collection, the data governance, the data warehouse, the data intelligence four big function modules to realize the concrete function.

Server--Software Monitor Center

Server is generally installed in the monitoring center and the core of the whole system. All the man-machine interface equipment access to the field equipment, long-term data storage ofthe field equipment, data statistical analysis and other related operations need to be coordinated and managed through the server, which is the link and bridge between the workstation, device and field equipment.

3.2.2 Human-machineInterfaceEquipment

One-Site Touch Screen Control

As a supplement to the workstation, simple operation and convenient installation location make the on-site touch control screen an indispensable part of the system.

The on-site touch control screen can operate independently from the cloud management center equipment to achieve the smallest control system; in the event of a cloud management

Mobile/IPAD Moving Control Device:

As a supplement to the workstation, simple operation and convenient installation location make the on-site touch control screen an indispensable part of the system.

Workstation:

A high-efficiency work platform with a friendly man-machine interface for workers in the field of industrial control applications.

Under the B/S architecture, the system supports parallel operation of multiple workstations (multi-users), which is flexible and convenient.

Handheld devices:

As a supplement to the workstation, simple operation and convenient installation location make the on-site touch control screen an indispensable part of the system.

Inspection panel switch:

In maintenance or emergency use, it can also replace the original circuit switch.

3.2.3 Local Management Center Equipment

As a management device connecting the previous and the next equipment,torealize the conversion of communication channels and the operation and management of local devices.

It is mainly used for loop dimming, multi-module integration, bus single-lamp controller control, etc.

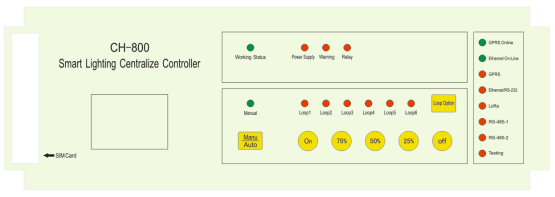

Centralized controller CH-800:

As a management device connecting the previous and the next equipment, it realizes the conversion of communication channels and the operation and management of local devices.

Mainly used for energy consumption management, PLC single-lamp controller, wireless single-lamp controller control, Hybrid PLC + LoRa Controller, 2700-6000K CCT Auto Changing Single Lamp Controller.

Smart Gateway:

As a management device connecting the previous and the next equipment, it realizes the conversion of communication channels and the operation and management of local devices.

Mainly used for switch circuit control,loopdimming control, lamp dimming control, lamp colors control, sensors control, etc.

3.2.4 Management & Control Equipment Terminal

3.2.5.1 Loop control level equipment

CH-HC201:

The max. control current (resistive load) of each loop is 30A. Multiple loops can be correlated with each other and can operate according to input signals from multiple sensors, with loop fault detection.

CH-H0102:

Single-loop switch control, to controlthe 3-Phase power line, needs to be used with an ACContactor.

The maximum loop control current (resistive load) is 5A. Can be cascaded, with loop fault detection.

3.2.5 Single lamp control level equipment

Individual lamp controller:

CH-D0001,CH-D0002,CH-D0004,CH-D1001,CH-D1002,CH-D1006,CH-D2001,CH-D2002,CH-D2005,CH-D5001,CH-D5002,CH-D5004, CH- D7001, etc.

Switching,Dimming the single lamp according to different models,will choose Industrial Bus, LORA, NB-IoT,power line-communication, and other channels.

With multi-functions on Fault detection and reporting, such as: lamp failure, communication abnormality, power supply failure, led chip failure, high temperature, etc.And functions of collecting electric parameters and measuring electricenergy.

Dual-lamp controller,

Multi-lamps controller:

CH-D0601,CH-D1601,CH-D1606,CH-D260,CH-D5601,CH-D2604,CH-D7601,etc.

Same function asthesingle lamp controller, which can control two or more lamps at the same time.

Dimming &2700k~6000k CCTauto changingcontroller:

CH-D0201,CH-D0202,CH-D0204,CH-D120,CH-D1202,CH-D2201,CH-D2202,CH-D520,CH-D5204,CH-D7201:

On the basis of theindividual-lamp controller,addingthe function ofdual colors(2700~6000K) auto-changing in different environment.

Hybrid PLC+ LoRa Controller:

CH-D6001,CH-D6002,CH-D6004,CH-D7401, etc.:

On the basis of theindividual lamp controller, one or two communication channels are added to realize the simultaneous operation of multiple communication interfaces.

3.2.6 Signal Repeater & Debugging Equipment

A variety of Repeaters, Copy Controllers, Monitors, and Debugging Equipment.