Kaolin Clay Slurry Press High Pressure Filter Plate Filtering Machine

Filter Press Characteristic:

1. The main parts of filter press is made of cast steel.The filter plates are made of high intensity HDPE, which could sustain high feeding pressure, the highest value could be 2.0Mpa.

2. The hydraulic parts adopting the contact meter to maintain the pressure automatically, saving labor cost, improve the working efficiency.

3. The machine structure is simple and reasonable, easy installation and maintenance.

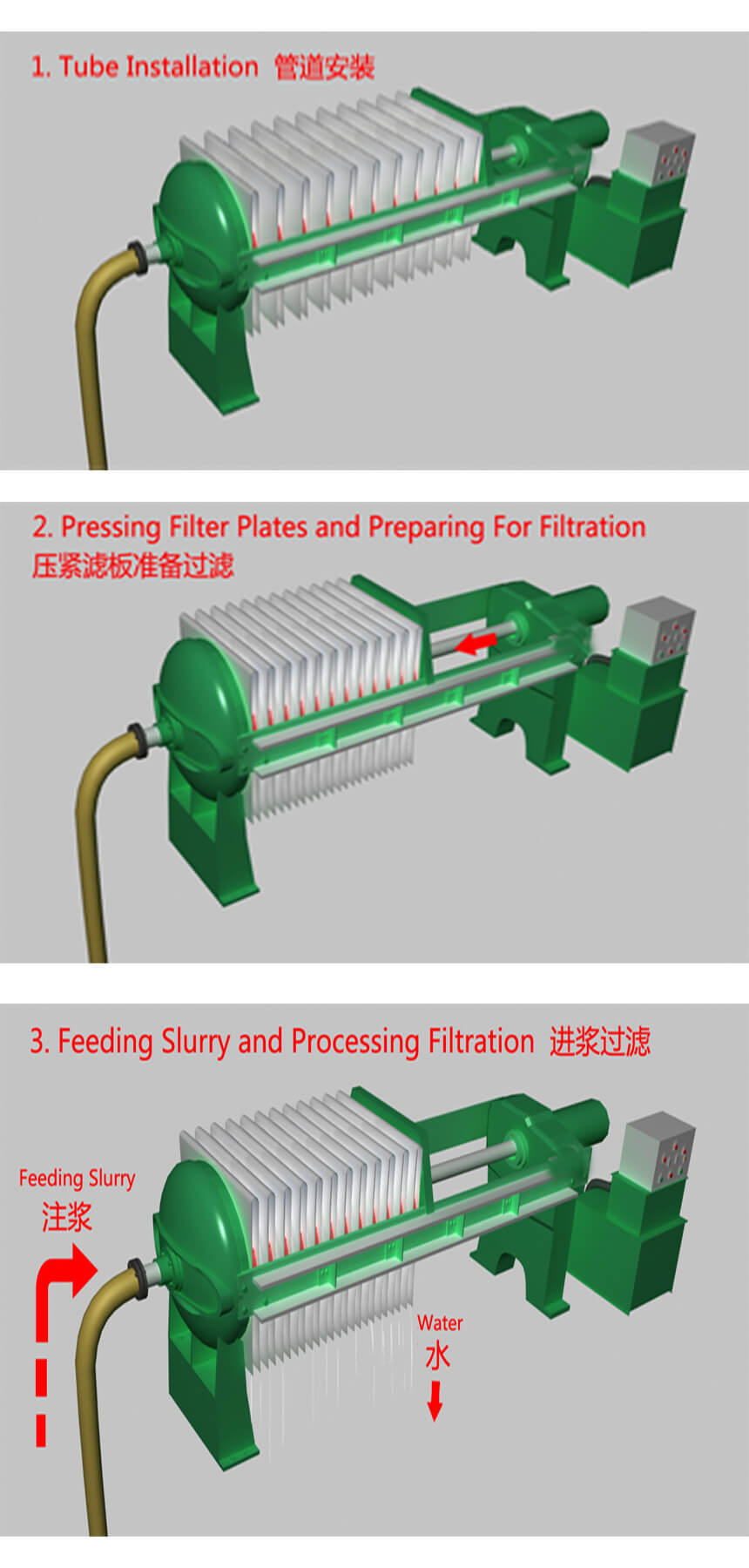

How Filter Press Work:

Ceramic plunger pump transports the slurry into the filter press from the feeding head, the chambers created by the plates are filled up with the slurry, the cloth (specifically developed for each material) and the high pressure dry the cakes, faster and better. The clean water is discharged into water collector, ready to be reused, and the cakes can now be disposed of easily.

Filter Press Application:

This filter press could be used in Mining, Waste water Treatment(Ceramic, marble, granite, glass and so on) , Kaolin, Clay, Sand Washing and other solid-liquid separation.

Filter Press Technical Parameters:

Model | Filter Area (m2) | Inner Size (mm) | Plate Thickness (mm) | Motor Power (kw) | Plate Number (Pcs) | Filter Capacity (L) | Working Pressure In Chamber (Mpa) | External Size (mm) L*W*H | Weight (kg) |

WYB-650 | 27 | Φ650 | 50 | 3 | 40 | 367 | ≤1.5 | 3950*1150*1170 4800*1150*1170 5800*1150*1170 | 2500 |

40 | 60 | 546 | 2700 |

54 | 80 | 725 | 3000 |

Plates quantity could be added or reduced according to customers' requirements. |

Other Introduction

In 2012, Relying on the advantages of Fujian Nan’an Machineries manufacturing base and optoelectronic information industry base, we founded another company Fujian Nanxing Environmental Technology Co., Ltd. invest heavily for new factory and new equipments, put into use in 2014.Through standardized and scientific management, we satisfies customers with the products and service better and better, creating more and more value for customers.