Materials

|

93% quartz powder, 7% resin and pigment.

|

Model No

|

SS5375 Autumn Snow

|

Specification

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

Thickness

|

12mm,15mm, 20mm,30mm etc.

|

Harness

|

7 Mohs

|

Modulus of Rupture

|

55.3 MPa

|

Flexural Strength

|

57.7 MPa

|

Application

|

Counter tops and Vanitytops, etc.

|

Surface finished

|

Polished,Honed, etc.

|

Packing

|

Wooden bundles for Slab, Styrofoam boxes and seaworthy wooden pallets

|

Payment Terms

|

T/T,L/C

|

If you’re planning to renovate your bathroom and a chic, modern space is what you’re after, quartz countertops may be a worthwhile addition to your wish list. Perhaps the best part of quartz countertops is their functional qualities, which make them perfectly suited for modern living. This material makes kitchen countertops:

-Ease of Maintenance,No bubble, clear more convenient

-Joint invisible, more beautiful appearance

-Most impervious of all surfaces; resists heat, stains, scratches, bacteria, fading

- Quartz is naturally dense and hard, making it highly resistant to chips and cracks.

-Quartz is extremely hard and makes for a good work surface.

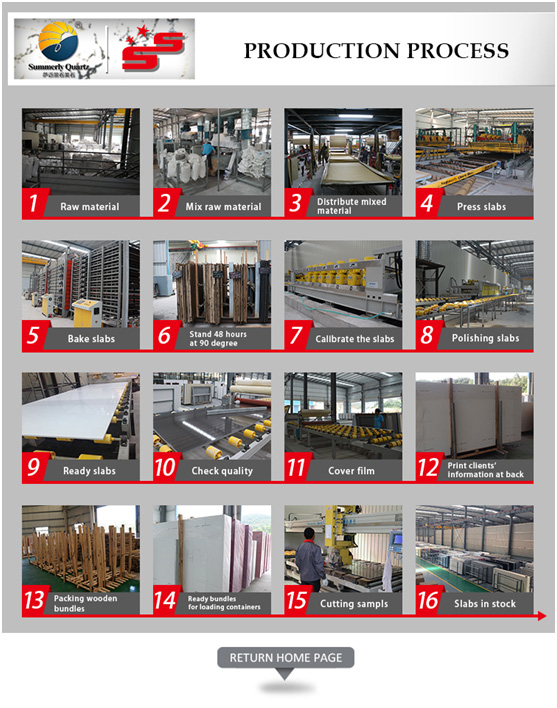

Production Engineering:

1. The process begin with a rigorous inspection of raw materials.

2. Feeding natural quartz raw material and polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed through quality inspection and packed with a plastic film.

Packing wooden crate (slab) wooden box (tiles/ countertop)