Medium Speed Crusher

As an efficient and energy-saving industrial crushing equipment, 420 medium-speed pulverizer has been widely favored in chemical, mining, metallurgical and other fields in recent years. Its unique crushing process and optimized structural design make it stand out among many crushing equipment and become the preferred crushing equipment for many factories.

At the heart of the medium-speed shredder is its innovative crushing mechanism. Different from traditional low-speed mills and high-speed cutting machines, medium-speed grinders use a high-speed rotating rotor to perform multiple impacts, cuttings and frictions on the material. Under the action of gravity, the material is quickly fed into the crushing chamber, driven by the high-speed rotation of the rotor, and undergoes a repeated crushing process. The rational design of the sieve strip can accurately control the discharge particle size to meet the requirements of various production processes. This unique grinding mechanism not only improves the grinding efficiency, but also significantly reduces energy consumption and noise.

Compared to conventional grinding equipment, medium-speed grinders offer a number of significant advantages. First of all, its crushing efficiency is significantly improved, and the output per unit power is greatly increased, which greatly reduces the unit energy consumption. At the same time, the equipment is suitable for brittle and medium-hard materials, such as gypsum, dolomite, coal, etc., and is widely used in chemical, building materials, metallurgy and other industries. In addition, the structure design of the medium-speed pulverizer is reasonable, the maintenance is simple, and the operator training cost is low, which greatly improves the production efficiency.

With the continuous improvement of industrial production requirements for material particle size control, medium speed pulverizers will play a more important role in the future. On the one hand, its excellent crushing performance and reliability will further strengthen its position in traditional applications. On the other hand, the future medium-speed pulverizer will also develop in the direction of more energy conservation and environmental protection, and further reduce energy consumption and emissions by optimizing the design and adopting high-efficiency motors. In addition, with the continuous expansion of the application field of the process, the medium speed pulverizer will play a greater role in emerging industries such as new energy, advanced materials and other fields.

In short, with its excellent crushing performance, low energy consumption and environmental protection characteristics, the medium-speed pulverizer will become an indispensable and important equipment in future industrial production, and has shown broad application prospects in many fields.

Key Features:

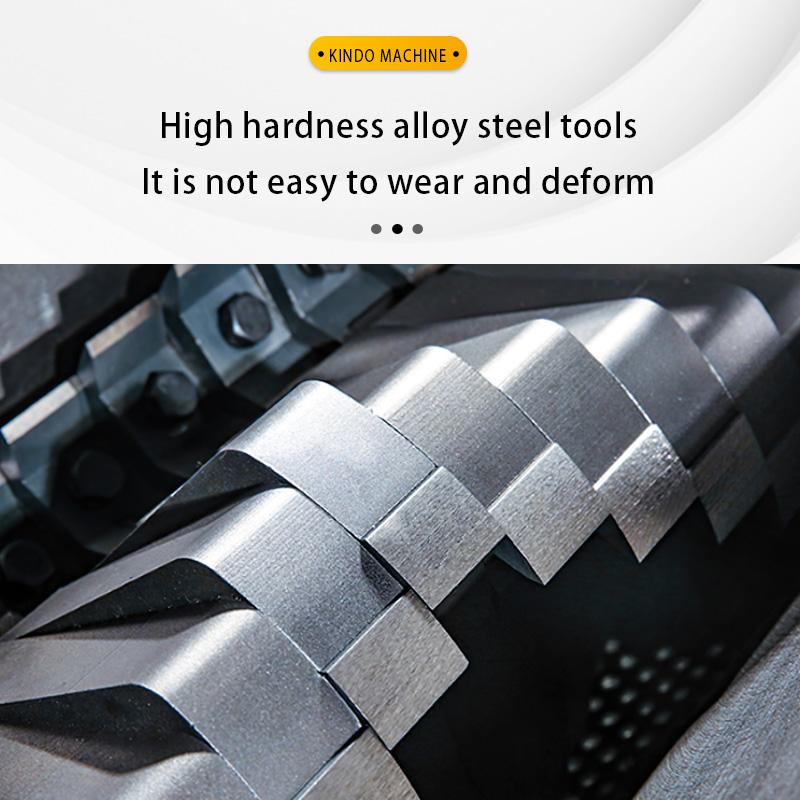

1. Efficient crushing: The unique crushing blade design and high-speed rotation mechanism can quickly and efficiently crush the raw materials to the required fineness.

2. Widely applicable: It can be applied to crush all kinds of brittle, fibrous and medium hardness materials, such as chemical raw materials, food, minerals, etc., with a wide range of applications.

3. Low energy consumption: Compared with the high-speed grinder, the medium-speed grinder has lower power, more economical and economical energy consumption, and more reasonable operating costs.

4. Convenient maintenance: The structure of the machine is simple and compact, and the daily maintenance and repair operation is easier and faster, which minimizes the maintenance cost.

5. Low noise: The unique sound insulation design and low-speed rotation mechanism make the noise generated by the medium-speed pulverizer more micro-low during operation, and create a quiet working environment for users.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.