Quartz Stone Composite Kitchen Sinks

Product Name

|

SS-C005 Capricom

|

Size

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

Thickness

|

12/ 15 /18 /20/ 30mm

|

Thickness tolerance

|

±1mm

|

Glossiness

|

>55 Degree

|

MOQ

|

100 Square meters

|

Resistance to Deep Abrasion

|

5×10-2g/cm2

|

Usage

|

Kitchen countertops, worktops, table tops,island tops, and so on

|

QC

|

Safe packing

Color differece control

Thickness tolerance: /-1mm

All products checked by experienced QC pieces by pieces and then pack

|

Package

|

Pack in strong wooden bundles (after fumigation) and each surface cover with PE film.

|

Payment term

|

T/T, L/C,etc.

|

Sample Request

|

Free Sample with Freight Paid by Customer

|

Whether you're creating a warm, traditional design or a more contemporary look, quartz can play a role. Quartz Countertops have the largest color selection,quartz countertops can add the perfect accent that you're looking to match your cabinets.Because quartz is a man made product, the color options are much more robust than you would find with a surface like granite. There are natural looking designs that imitate marble, with a white base and light veining. You can also find the speckled look that imitates beautiful granite countertops. If you want a countertop that will flow nicely with the rest of your home, then quartz countertops will be the right choice. For an entirely cohesive look anywhere in your home.

Quartz can live in homes with little worry of constant maintenance or replacement.Because it is so durable, it is safe from the stain that oils ,wine,or other food can have on other surfaces. There is also no need to constantly reseal its surface. They resist staining and corrosion. Quartz is also scratch resistant too which makes it absolutely superb for being used in the kitchen areas as a work surface. In the kitchen, you will never have to worry about slipping with the knife when you are prepping your meals as it is incredibly difficult to scratch the surface.

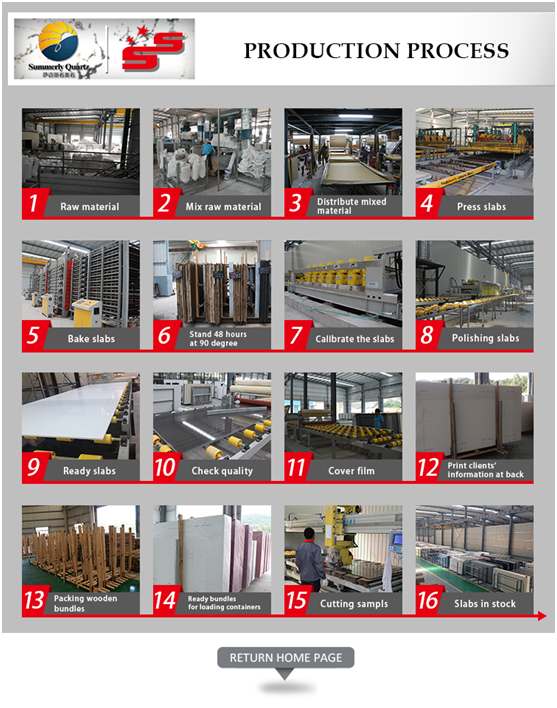

The Production Process:

1. The process begins with a strict inspection of raw materials.

2. The natural quartz raw material and polymer resins and inorganic pigments are put into the mixers and mix together.

3. After mixing, pour them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special vacuum and vibration process at pressure machine.

5. Then the slab is moved to the curing kiln and heated for a period time to make their final strenth and srurdiness.

6. Cut edges, flat , thicknessing and polishing surface to perfect finished.

7. Finally, through quality inspection and plastic film packaging.