Optical fiber laser cutting machine

Characteristics of our laser cutting machine

1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process.

|

Product Parameters

|

|

Brand and manufacture

|

BCSK LASER

|

Machine Model

|

BCL-3015

|

|

working area

|

1500*3000mm

|

Laser power

|

Selectable

|

|

Machine weight

|

4600KG packing

|

Fiber laser Generator

|

Max,IPG Brand,nLIGHT,ect

|

|

Laser wavelength

|

1070mm-1080mm

|

Laser Beam quality

|

<0.373mrad

|

|

Worktable

|

Sawtooth with pneumatic easy

moving attachment

|

Fiber Laser cutting head

|

Switzerland Raytools auto focusing

|

|

Focus lens

|

Raytools

|

Working life of fiber module

|

More than 100000 hours

|

|

Motors & Drivers

|

YASKAWA servo motor made in

Japan or other imported

|

Reducer

|

Japan Shimpo

|

|

Guide Rails

|

High accuracy linear brand from

Taiwan

|

Transmit system

|

DUAL drive rack and pinion 4 Focus lens

|

|

Chain system

|

Enclosed high quality

|

Water Chiller

|

Hanli or Tongfei

|

|

Control system

|

Professional laser control

system--Cypcut

|

Position type

|

Red Dot pointer

|

|

Cutting thickness

|

≤5mm(stainless steel)

|

Max. Idle Running Speed

|

100M/min

|

|

≤12mm(carbon steel)

|

|

Geometric Position Accuracy

|

within ±0.08mm/M

|

Max Cutting Speed

|

32M/Min

|

|

Reorientation accuracy

|

within ±0.05mm/M

|

Lubrication system

|

Auto Electrical motored,wholly and sound

|

|

Min. Line Width

|

±0.02mm

|

Power Consumption

|

10-13KW total

|

|

Power supply Voltage

|

380V/50Hz/60Hz

|

Auxiliary gas system

|

Japan SMC series components, dual air inlets,

low pressure piercing , automatic pressure

adjustment and switching

|

|

Auxiliary Gas for cutting

|

Oxygen, Nitrogen, Air

|

Compatible software

|

Autocad, Coreldraw, etc

|

|

Graphic format

|

DXF/PLT/AI/

|

Working method

|

Industrial PC control with console desk and

romote

|

|

Total power protection rating

|

IP54

|

|

|

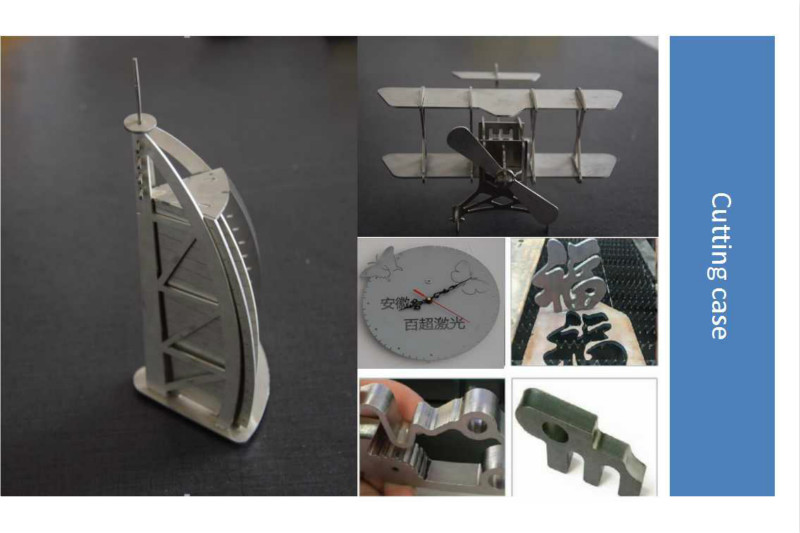

Appicable Industry and Cutting Samples

This machine is widely used in various industries such as advertising decoration,kitchen ware,engineering machinery,steel and iron,automobile,metal plate chassis,air-conditioner manufacturing,metal plate cutting,etc

Pre-sales & After-sales service commitment

Pre-sales service:

Free sample making

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Try before you buy.

Progressing Solution Design

According to customer's product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

After-sales service:

Training to install:

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/SKYEPE/Wechat and so on, when you meet some problems of installation, using or adjusting. (Recommended)

B. You can come to BCSK Laser factory for training. BCSK Laser will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

C. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator for both of our engineers during the training period. Training Time: 5~7 days

Remark: The charge of air ticket, accommodation expenses in your country will burden by your side.