Product and working principle:

MFP plug-in

electromagnetic flowmeter is a new type of fluid flowmeter developed on the basis of pipelin magnetic flowmeters. On the basis of retaining the merits of pipeline electromagnetic flowmeter, aiming at the difficulty of installing large pipeline and the defect of cost headlamp of pipeline electromagnetic flowmeter, according to the principle of NIKURADS, the average velocity of fluid is measured by electromagnetic method to obtain the volume flow of fluid. Especially after adopting the technology of pressure opening and pressure installation, the plug-in type magnetic flowmeters can be installed without stopping the mechanical (water) condition, as well as on cast iron pipes and cement pipes. The successful development of the

plug-in electromagnetic flowmeter provides a new means for the detection of fluid flow.

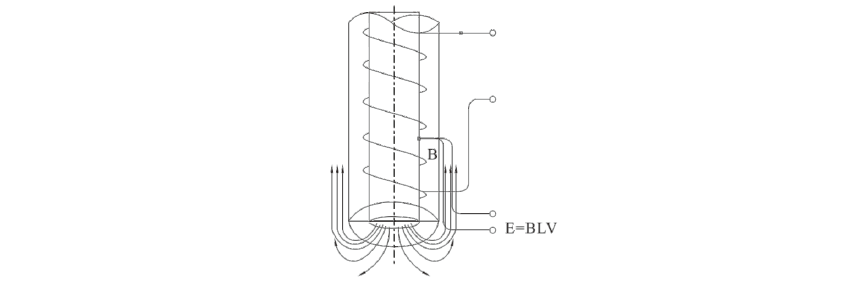

Unlike the general electromagnetic flowmeter, the sensor of the

plug-in electromagnetic flowmeter is a magnetic field emitted from the outside. The principle of the electromagnetic flowmeter is shown by the measuring electrode at the end or both sides of the sensor (as shown below). It is noteworthy that the induction signal of the electromagnetic velocity sensor emitted by an external magnetic field is affected by the thickness of the boundary layer between the fluid and the magnetic field, which will reduce the linearity of the measurement.

For MFP plug-in electromagnetic flow meter, the conductive liquid in the pipeline is the conductor moving in the magnetic field, and the distance between the two electrodes is the length L of the conductor. Its induced voltage is proportional to the average velocity of flow. In this case, the flow rate of fluid in the pipeline can be derived from this formula.

Q = 兀D

2U/4KBL

D: Measuring inner diameter U: induced voltage B: magnetic induction intensity

K: Coefficient related to magnetic field distribution

Product composition

Product composition

A set of MFP plug-in electromagnetic flowmeter is composed of sensor and converter. According to the protection level and parameter setting, two different types are formed:

1 > integrated installation of sensor and converter,

2 > separate installation of sensor and converter.

Integral installation is to connect sensors and converters through the interior to form a whole, which directly outputs current or frequency signals linearly related to the flow rate. This kind of launch has been done well when it is out of the factory, and all parameters have been adjusted according to the user's requirements.

Separate installation is to connect sensors through external shielded cables, which constitute a complete electromagnetic flowmeter. The parameters of the converter can be adjusted according to the user's requirements and process data. This method is suitable for diving/immerged and other occasions.

Conditions of use:

Conditions of use:

Ambient temperature: - 25℃ ~60 ℃

Power supply: AC100V-230V, DC11V-40V

Working power: <20W

Environmental humidity: 5%~95%

The highest material temperature is 80℃ (one body) and 120℃ (split body).

The characteristics of plug-in electromagnetic flowmeter are as follows:

-

Insertion electromagnetic flowmeter is simple to install, does not need to cut off the current, and can open the hole with pressure on the spot. It has absolute installation advantages and price advantages.

-

plug-in magnetic flow meter is suitable for liquid flow detection with conductivity above 5us/cm in water, sewage, acid and strong alkali. The change of conductivity does not affect the change of performance and the complex change of strong using fluid. It is especially suitable for flow measurement of drainage pipes.

-

The accuracy of measurement can reach the indication value (+0.5%~1.0%), and the flow in both front and oppiste side of directions can be measured. This provides a good method for accurate flow measurement.

-

The flow measurement is only related to the depth of insertion, so the flowmeter has wide versatility and strong interchangeability. One type can be applied to the fluid measurement requirements of pipelines of various specifications.

-

The instrument adopts dual-frequency excitation mode, which is not affected by power frequency and works steadily and reliably.

-

Converter has good interchangeability and accuracy can be achieved without re-calibration of current.

-

Small signal excision function. Users can set the lower limit voltage and the lower limit flow through the display panel to remove the interference small signal flow.

-

Converters and sensors have a variety of protection levels and installation methods, and IP68 level is suitable for diving installation.

Magnetic flowmeters technical data

|

Model No .MFP

Plug-in type magnetic flowmeters

|

|

One body

|

Split body

|

Regular Error range

|

±2%/5% of display value

|

|

Carliber(mm)

|

DN200~DN3000

|

DN200~DN3000

|

|

Flange material

|

stainless steel

|

|

Pressure grade

|

1.6MPa

|

|

Converter Shell material

|

Aluminum Die Casting Alloys

|

|

Sensing element shell material

|

Stainless steel

|

Sensing element Structural material

|

Stainless steel ,PVDE

|

Electrode

|

316L/Hastelloyalloy/Titanium/ tantalum,/Platinum, gold

|

Electroconductibility

|

≧ 5μs/cm

|

Protection grade

|

IP65/IP67

|

IP65/IP67(sensing element IP68 available)

|

Enviroment Temperature

|

25℃~60℃

|

EnviromentTemperature effect

|

﹤±1%/10℃ or ±0.25%/10℃

|

Medium temperature

|

-25℃~80℃

|

-25℃~120℃

|

Repeatability

|

﹤±1%/ ±0.25%

|

Analog output error

|

≤0.02mA

|

|

Measuring range flow rate

|

0.3m/s≤V≤10m/s

|

|

Embeddability

|

Null

|

≤5m (only for IP68)

|

Electrical connection

|

M20*1.5 seal gland ,G1/2,NPT1/2

|

Sensing element cable

|

Null

|

≤30m (any more should contact us )

|

Output interface

|

Standard(pulse+4mA~20mA +single current output),RS485 output,HART

|

Outline Dimension

Size of sensor

The fixed method of sensor is flange connection. First, the length of the base connecting pipe is calculated according to the diameter of the pipe, and then the pipe openings are made. The base is welded to the pipe openings. When welding, the correct orientation and insertion depth of the flange bolts of the main base should be absolutely determined, so as to ensure that the probe direction of the sensor is perpendicular to the direction of the fluid. The base connecting pipe should not exceed the inner wall of the detected pipeline to ensure the smooth inner wall of the outer pipeline.

Specific dimensions and material specifications and models are shown in the figure.

(1) DN200 mm, DN300 mm, DN400 mm (no pressure installation)

|

No.

|

Name/Carliber(mm)

|

DN200

|

DN300

|

DN400

|

|

1

|

Sensor(LxΦ)

|

182xΦ38

|

|

2

|

Flange

|

DN40 1.6MPa

|

|

3

|

Connectiong Pipe

|

Φ45

|

|

4

|

Pipeline

|

Φd XS

|

Installation Principle:

Installation Principle:

Ensure the depth of electrode insertion into water pipe

H=(D-2s)X10%, A=182-(h+S) (that is, 10% of the pipe diameter)

Note: In case the production device is not allowed to stop flow, the selection can be carried out with pressure installation. Firstly, weld the base directly to the installation position of the measuring pipeline, then install the ball valve at the upper root, and then open the hole. The hole is Φ45 mm~Φ50 mm (we can provide special pipe opener, hole opener is an optional purchasing parts ). After the hole is opened, close the ball valve, the fluid will not spill. Then connect the seal provided by the manufacturer, and install the sensor. (Pressure installation does not affect normal production). Specific dimensions are as follows: