Main Features:

1. Adjustable filling range. (10-100ml, 20-250ml)

2. Filling Nozzles can be customized according to the size of your bottles/Jars.

3. 35L Hopper can be customized.(Mixing and Heating is optional)

4. Pedal and Automatic filling are available.

5. Fully pneumatic control, doesn't need electricity, Safe and easy to operation.

6. Pneumatic components useTaiwan's AirTac. More durable.

7. Connect partsare made for 316L Stainless steel, other parts are made for 304 stainless steel, Meet GMP Standard.

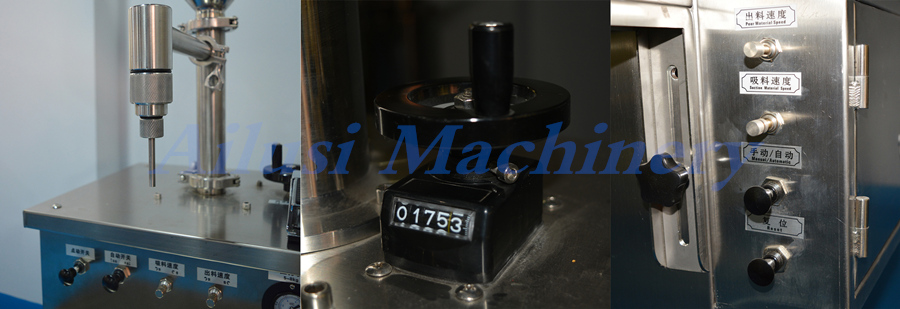

Details of Vertical Filling Machine:

● Contact parts are made for 316L Stainless steel, other parts are 304 Stainless steel, Sanitary Grade Standard.

● Quick open cartridge, removable, easy to clean;

● Normal gravity type

feeding products.

● Piston cylinder

control volume, High accuracy, the error is only 1%

● Movable wheels, easy to remove.

● The height can do customized, can be equipped with Cream Feeding Pump, Semi-automatic Capping Machin, Semi-automtic Labeling Machine.

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.