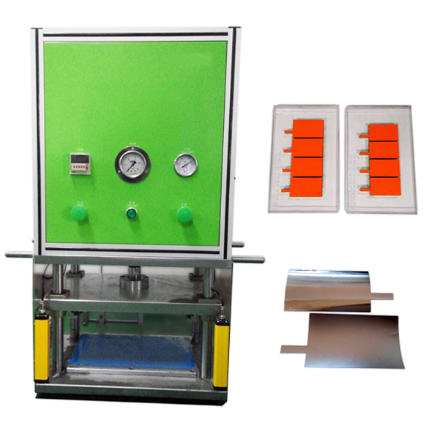

Pouch Cell Sealing Machine Vacuum Sealer for Li ion Battery Assembly

It mainly used for the first vacuum sealer of punch/polymer battery (soft-pack)lithium cell after injected and final sealing.

1)lithium battery pouch sealer can suitable for different specifications of battery,easily to adjust,only do the speed regulation(or change)clamp and adjust(or change)the related sealing head ok.

2)There are battery pressing platen within the upper cabinet,to press the battery tightly and make the welding effrect better.

3)The sealing-head is made of copper materials, heat transfer effect is good save power consumption,improve work efficiency.

4)The head temperature can set through the thermostat panel button control, the current value of the temperature and the set point can be through its LCD screen display, intuitive and easy operation.

Working principle

This equipment is used the tilt(flip type)to form a closed cavity,then pump the air in the cavity to form -90KP of in a negative pressure state,so that make the air within batteries core excluded.

Platen of the upper chamber use the cylinder pressing materials,and then trough sealing head using the heat conduction effect acting on a lithium battery packaging material(aluminium-laminated film),and heated close to the molten state softened and fused together.

|

Model

|

Compact Vacuum Sealer TMAX-YF

|

|

Source voltage

|

AC 220V/110V, 50/60HZ

|

|

Power

|

600W

|

|

Warranty

|

Two years limited warranty with lifetime support

|

|

Advantages

|

1 Sealing Head adopts copper material, good heat transfer effect,

2 Can apply to different sizes of battery

|

|

Vacuum degree

|

-95Kpa - 0

|

|

Sealing head

temperature

|

RT-250℃, adjustable

|

|

Temperature accuracy

|

±1.5℃

|

|

Sealing

pressure

|

0-7Kg/cm2, adjustable

|

|

Sealing time

|

0-99s, adjustable

|

|

Sealing Blade

|

Hard type (without rubber, only for Al case sealing,

not suitable for sealing case with tab in between)

If you need heat sealer for Top&side sealing with rubber blade,please click the pic below

|

|

Sealing width

|

Customized according customer's request

|

|

Sealing head

length

|

Standard sealing length: 200mm

The sealing length can be customized according customer's request(100-500mm selectable)

|

|

Air source

|

0.5-0.7MPa (72.5-102psi)

|

|

Dimension

(L*W*H)

|

Sealing Unit with Chamber Closed: 470*430*480mm

Sealing Unit with Chamber opened: 470*430*559mm

Control Unit: 420*320*220mm

|

|

Weight

|

About 50kg

|

|

Note

|

For completing the full sealing procedure, you may need the following combination:

a.Compact Heating Sealer(suitable for top&side sealing with tab)

b.Vacuum Sealing Machine(for pre-sealing in glove box after injection of electrolyte)

c.Final Vacuum Sealing Machine

(for vacuuming and second sealing with automatic puncture and degassing function)

If you don't want to spend too much budget on the sealing part, we also can provide 3 in 1 sealing machine for you:

|

|

Recommendation

|

For the pouch cell assembly, we also recommend you the following items:

Forming machine Ultrasonic tab welder

Stacking machine Die Cutter

|