Masterbatch Machines

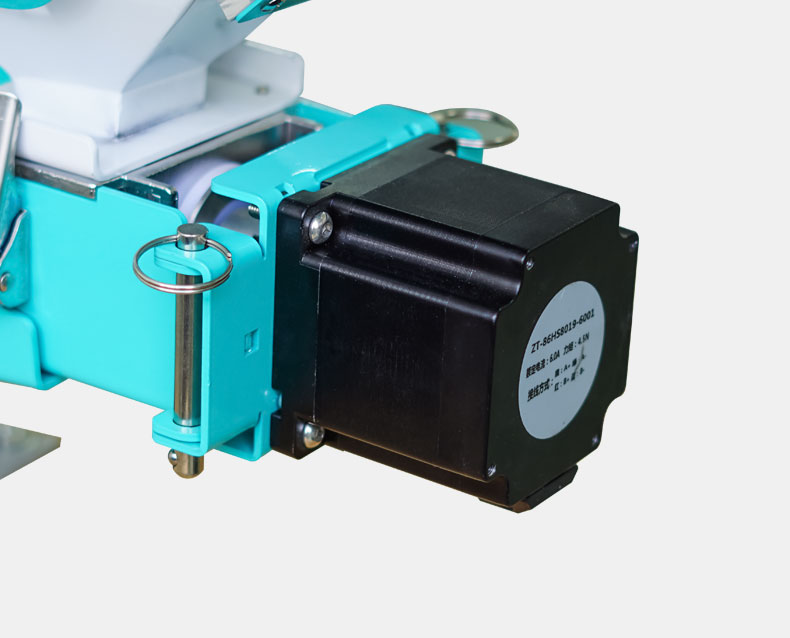

Modern masterbatch machine is constantly innovating in technology, adopting a variety of advanced designs and functions to meet the production needs of different users. First of all, masterbatch machines are usually equipped with highly efficient screw systems, which are finely optimized for efficient material mixing at low energy consumption. The different designs of the screws can be adapted to the characteristics of different masterbatches and substrates, ensuring optimal melting and mixing results.

Secondly, modern masterbatch machines also introduce an intelligent control system, which can monitor various parameters in the production process in real time, such as temperature, pressure and mixing time. This automatic control not only improves production efficiency, but also reduces the error caused by human operation, ensuring the stability and consistency of the product. At the same time, users can easily set up and adjust through the touch screen interface, which greatly improves the convenience of operation.

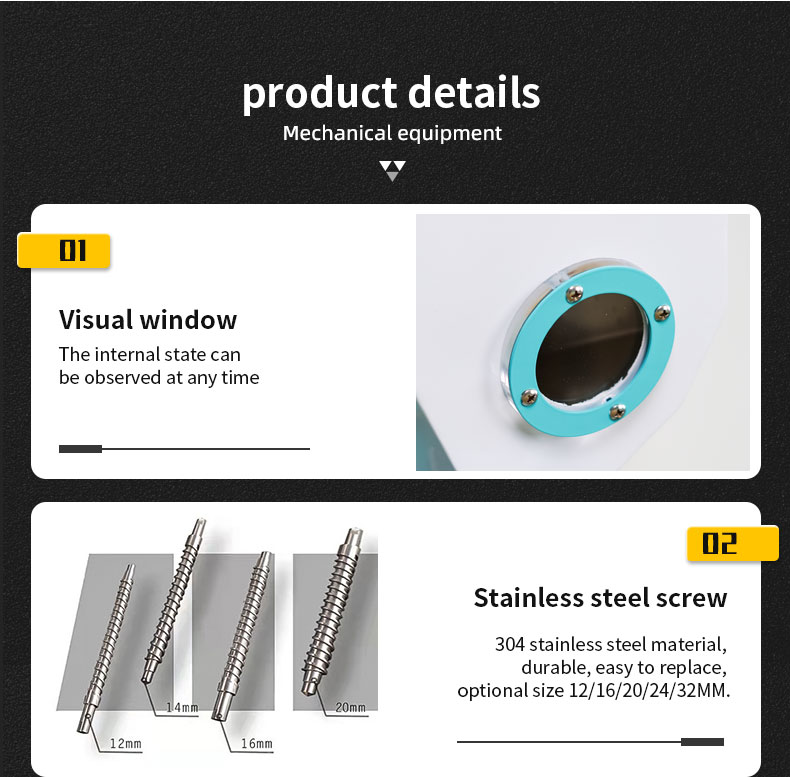

In terms of safety and environmental protection, many masterbatch machines adopt a closed design and a high-efficiency filtration system, which effectively prevents the leakage of dust and odors. This design not only protects the health of the operator, but also reduces the environmental impact. In addition, the masterbatch machine is very easy to clean and maintain, and the equipment is usually removable so that the user can quickly replace parts, reducing downtime.

Finally, the versatility of the masterbatch machine allows it to adapt to different production needs, allowing users to quickly adjust production schedules according to market changes and flexibly respond to various challenges. Overall, modern masterbatch machines, with their advanced technical features and flexible production capacity, provide strong support for the plastics processing industry and help enterprises gain a competitive advantage in the market.

Key Features:

1. Efficient mixing performance

Advanced mixing technology is used to ensure that the masterbatch and substrate are fully and evenly mixed, improving the color dispersion effect and meeting strict production standards.

2. Intelligent operating system

Equipped with a user-friendly intelligent control interface, real-time monitoring of mixing status, simplifying the operation process, reducing human error, and improving production efficiency.

3. Durable structure design

It is manufactured with high-quality wear-resistant materials to ensure long-term stable operation of the equipment in a high-intensity working environment, reduce maintenance costs and prolong service life.

4. Energy saving and environmental protection

The design is optimized to reduce energy consumption, reduce material waste in the production process, meet modern environmental standards, and help enterprises achieve sustainable development.

5. Wide adaptability

It can handle many types of plastics and masterbatches, flexibly adapt to the needs of different customers, and is suitable for various industries, such as plastic processing, packaging, etc.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.