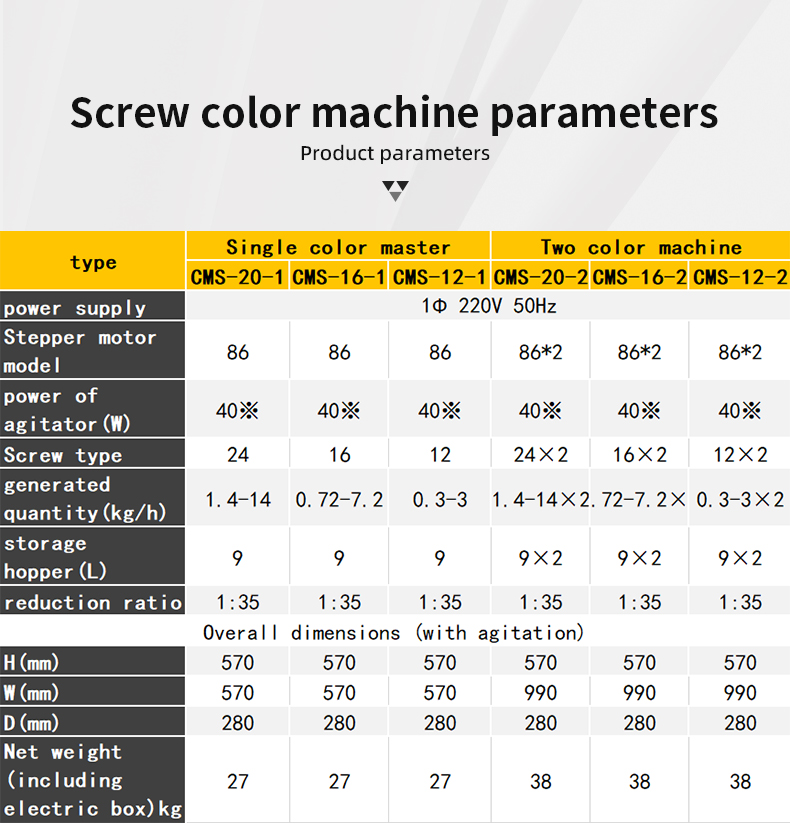

Masterbatch Machines

Masterbatch machines are widely used in many industries, and their main function is to provide color solutions for a variety of plastic and rubber products. In the plastics industry, masterbatch machines are used in the production of a wide range of everyday products, packaging materials and electronic components to ensure that products are attractive in appearance and competitive in the market. For example, in the field of food packaging, masterbatch machines are able to effectively provide vivid colors and make products more eye-catching.

In the automotive industry, masterbatch machines also play an important role. The color consistency and stability of automotive interior and exterior trim parts directly affect consumers' purchase decisions. With the help of the masterbatch machine, manufacturers can quickly adjust and produce auto parts that meet market demand, improving production flexibility and product quality. In addition, the masterbatch machine can also be used to produce various automotive plastic parts, such as instrument panels, door interiors, etc., to ensure color durability and wear resistance.

The pharmaceutical and cosmetics industries are also important markets for masterbatch machines. In pharmaceutical packaging and medical devices, masterbatch machines are used to ensure the recognizability and aesthetics of the product. For the cosmetics industry, especially skin care products and cosmetic packaging, the masterbatch machine can provide a variety of color options to help brands create a unique market image.

To sum up, the masterbatch machine has a wide range of applications, and with its efficient coloring ability and flexible production methods, it provides high-quality color solutions for many industries and helps enterprises stand out in the fierce market competition.

Key Features:

1. Efficient mixing performance

Advanced mixing technology is used to ensure that the masterbatch and substrate are fully and evenly mixed, improving the color dispersion effect and meeting strict production standards.

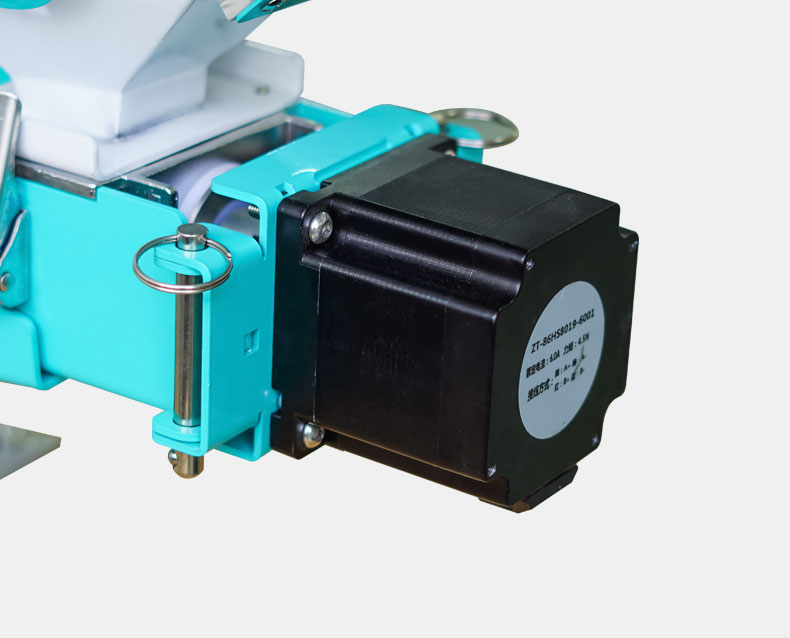

2. Intelligent operating system

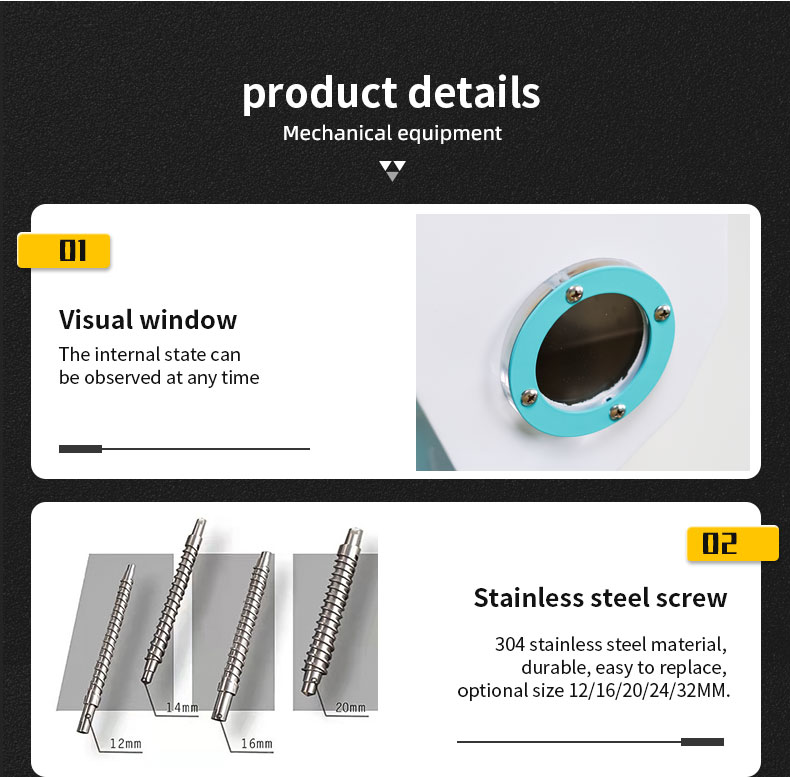

Equipped with a user-friendly intelligent control interface, real-time monitoring of mixing status, simplifying the operation process, reducing human error, and improving production efficiency.

3. Durable structure design

It is manufactured with high-quality wear-resistant materials to ensure long-term stable operation of the equipment in a high-intensity working environment, reduce maintenance costs and prolong service life.

4. Energy saving and environmental protection

The design is optimized to reduce energy consumption, reduce material waste in the production process, meet modern environmental standards, and help enterprises achieve sustainable development.

5. Wide adaptability

It can handle many types of plastics and masterbatches, flexibly adapt to the needs of different customers, and is suitable for various industries, such as plastic processing, packaging, etc.

FAQ

1) Are you manufacturer?

Yes, we are manufacturer over 10 years' experience.

2) How can I place order?You can contact us by email about your order details, or place order online.

3) What's the order procedure?We issue you Proforma Invoice after you confirm the order. And then You make the payment for the deposit before we go into production.It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?You can make payment by T/T (telegraphic transfer) ,Western Union,Moneygram and L/C.

5) Do you have manual with the machine?Yes, of course. It is in English version. We will send it with the machine.

6) Can you offer us the necessary paper to do the customs clearance?Yes, of course. We will send you all paper you need.