|

Item Name

|

SS5820 Black & White

|

|

Color

|

Black,white,Brown,red,blue,etc.

|

|

size

|

Slabs

size: 3000x1400mm,3000x1600mm, 3200x1400mm,etc.

Countertop: 48*26".

70*26", 78*26", 96"x26", 108"x26"

Vanity top:

22"x25", 22"x31",

22"x37", 22"x49", 22"x61", 22"x73",etc.

|

|

Thickness

|

12mm,

15mm, 18mm, 20mm, 30mm.etc.

|

|

Thickness Difference

|

1.0mm

|

|

Bulk Density

|

>2.30g/cm3

|

|

Usage

|

Wall,Floor and Inner

decoration for Ceiling, Kitchen Countertops, Bathroom vanity top,

Fireplace, and Window Sills, etc.

|

|

Payment Terms

|

30%

T/T deposit in advance before production arranged. 70% T/T balance payment

before delivery from factory

|

|

Packing

|

Strong

wooden crates with fumigation worthy to seafreight.

Wooden

crate is 2.3cm thickness, with foam and plastic for water resistence

|

Engineered quartz is man made which means

you can get quartz countertops in a variety of colours and patterns. It can instantly improve the aesthetic value

of your kitchen countertops. The technology used to make quartz gives it

additional benefits that natural stones don’t have.

Quartz tops are highly durable and almost

indestructible. Bacteria takes a very long to take hold of these countertops.

They are maintenance free. This ultra

clean, hygienic option is safe for the entire family since it is non-porous and

non-toxic. Quartz also resists scratches, stains, heat, and mold.

For a contemporary, upscale look with very

low maintenance required, quartz countertops are definitely worth considering.

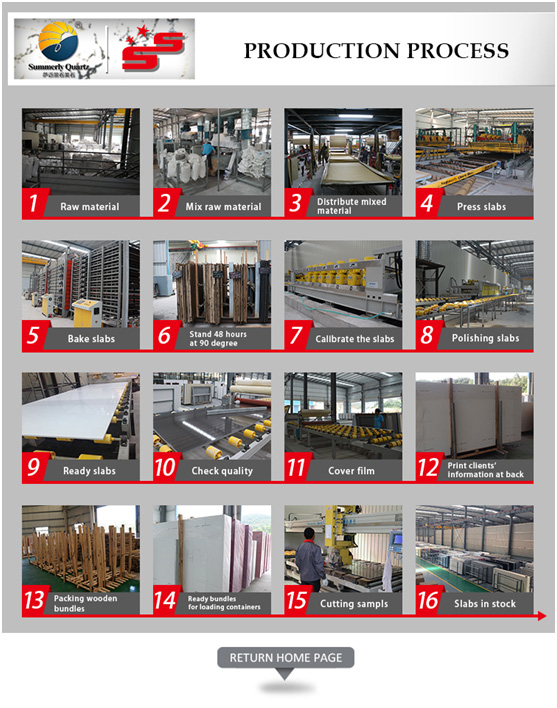

The Production Process:

1.

The process begins with a strict inspection of raw materials.

2.

The natural quartz raw material and polymer resins and inorganic pigments are

put into the mixers and mix together.

3.

After mixing, pour them into a mold and form them into slab size.

4.

Pressing: Then the slab is compacted by a special vacuum and vibration process

at pressure machine.

5.

Then the slab is moved to the curing kiln and heated for a period time to make

their final strenth and srurdiness.

6.

Cut edges, flat , thicknessing and polishing surface to perfect finished.

7.

Finally, through quality inspection and plastic film packaging.

Sample Room: